I ended up making a new tool rest for my bench grinder. I had been using the stamped metal bracket that came with it. I didn't make a super fancy replacement capable of sharpening end mills, etc. -- that's a project for another day.

I just put together materials on hand, namely some angle iron sections of a bed frame, a spare strap hinge, and some steel cutoffs, spot welded together. But it's a hundred times better than the grinding rest that came with the machine!

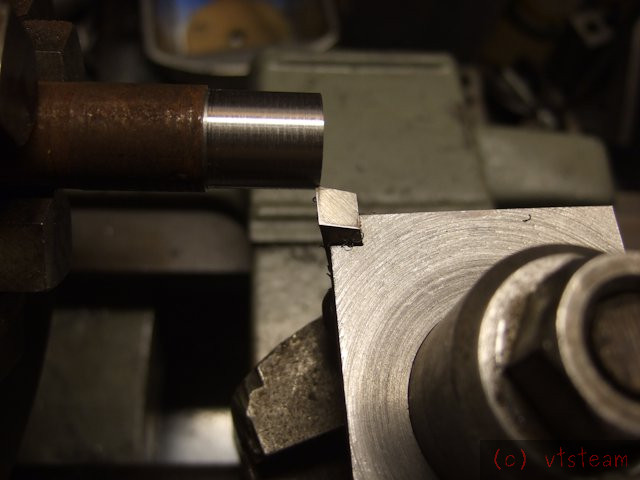

Then I was able to make a new tool bit for the tangential tool holder, and I got a true 28 degrees, measured, for the cutting face.

I honed it on a little diamond hone and tried it out on the same chewey steel test bar I had earlier. It gave the smoothest finish I've been able to achieve so far -- a personal best. Probably not as good as others can achieve, but It feels shiny smooth, which is a big improvement for me. I do see some slight regular variation in surface appearance, but I'm thinking that is probably due to lathe vibration and lead screw. I need to make a more solid base for the lathe than I have right now. The whole table top shakes.

Very happy with this tool post! I might reserve it for finish use, though. I'm not sure it's suitable for taking heavy cuts.

Here's a current picture: