I have spent a few years researching the drawing records of the Lima Locomotive Works and I have drawn 5 Shay locomotives and a really nifty geared 4 wheel critter with side rods all from original Lima records. The bulk of this work appeared in "Steam in the Garden" a small mom and pop magazine that was edited by the late Ron Brown a steamup buddy of mine and a real friend to the G1 live steam community,

The series of articles I wrote was titled The Nuts and Bolts of Shays and they are about the engineering of Shay locomotives. The series concluded with several articles that included all the drawings I could locate for Shop number 2800. This was a small 2' gauge 10 ton Shay with 2-6"x10" cylinders that ran at the Mapleton Tramway in Queensland Australia.

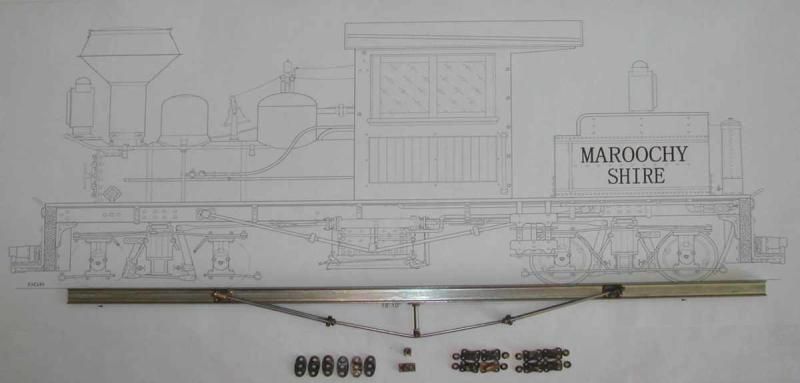

Issue #100 was the start of the Mapleton section Ron gave me a double fold out so the full up drawing was printed in the build scale of 7/8" to the foot. Both sides and the front and back of the locomotive are drawn full model size.

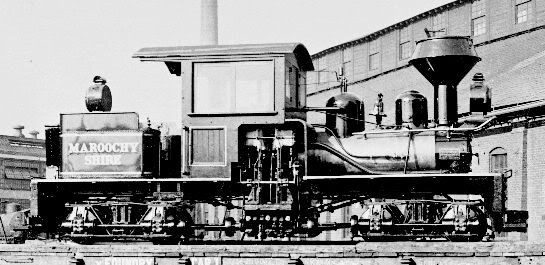

Here is the photo of Shop number 2800 posted with permission of the Allen County Historical Society Lima Ohio.

The frame seamed like the logical place to start so I had to think about milling scale I beam to get a good looking model. I have tried several ways that did not give satisfactory results so this time I used a 10

0 tapered ball end mill after the 1/2" square 12L14 stock was roughed to size. Here is the set up for the mill.

I found out right off that I had to make the same cut on both sides of the frame stock to prevent warping. Here is the photo of the first attempt that proved that concept.

Here is the finished I beams and some channel stock for final inspection.

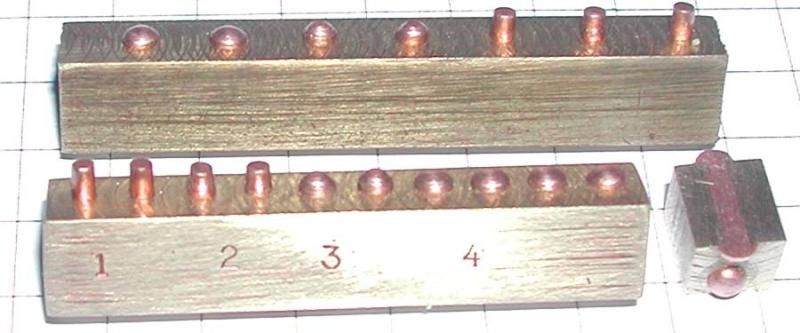

Next up is a bit of rivet practice, the tools are modified versions of what is in the Harris boiler book fitted to a heavy duty Starrett automatic center punch.

The small section of brass stock is a guide that is 1.5 times thicker than the body of the rivet so i can use the flush cutter to leave the proper amount to from a rivet head the bucker for the vise is also shown.

Here is an early practice run the numbers more or less match what is in the boiler book but I reduced the operation to two dies for the center punch.

Here is a couple of master patterns. The truss pads are right and left handed so I made a single master that the angle can be adjusted for either way. The left and right core are also shown. The little truss post guide was tricky to machine, I am really glad that I only have to make one of those. The grid is 1/4" square.

Here are the parts for a test fit. The frame is 19.25" long.

More to come to catch up to date.

Dan