One of the things I realized in all of this was that there were three ways to adjust a Z axis in horizontal milling machines. The first is to have a knee or slide with the work on it. The second, less common way is to have the mill head adjustable in the Z dimension. Gingery's horizontal mill uses this method.

The third method which I had here developed for my lathe was to make a set of adjustable fly cutters to provide adjustment range up to the center height of the lathe These could be mounted on an arbor between centers, or a stub fly cutter. However this was mainly to be an intermediate stage in producing a vertical slide type, and in fact a rotary table version of that so I could mill the Tesla ports.So the next stage was casting the vertical ways and slides, which would ride on the boring and milling table as an accessory.

I would now use the milling table to finish those parts instead of laboriously filing and scraping them into bearing. I decided also that maybe I could re-use the library of slide patterns I'd already created in making the lathe. So I standardized on their dimensions, and realized I could add removable adapters to the patterns where they needed to be different than what was required by the lathe.

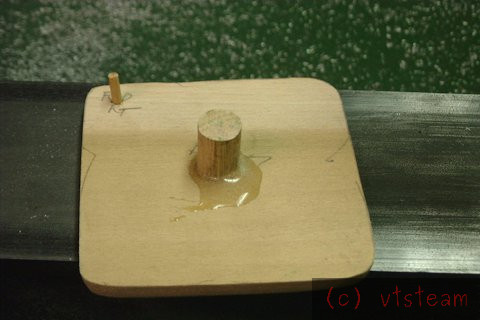

Here is one of the adapter pattern pieces being glued up.

.