I have made a bit of progress on this project. I have nearly all of the frame castings done so that section is nearly complete.

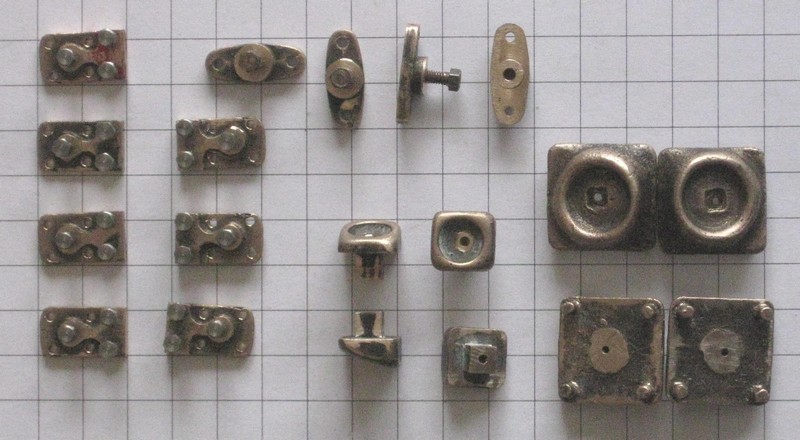

I made the push pole pocket and the frame brace pad from metal so a rubber mold is a one step process to get castings. Here are the Mapleton push pole castings and the frame brace pads.

With more complex parts I usually start with wax and cast a metal pattern. Here are the patterns for the steam jamb and old style push pole pockets for the Dulong, brake rods and the boiler pad clamp.

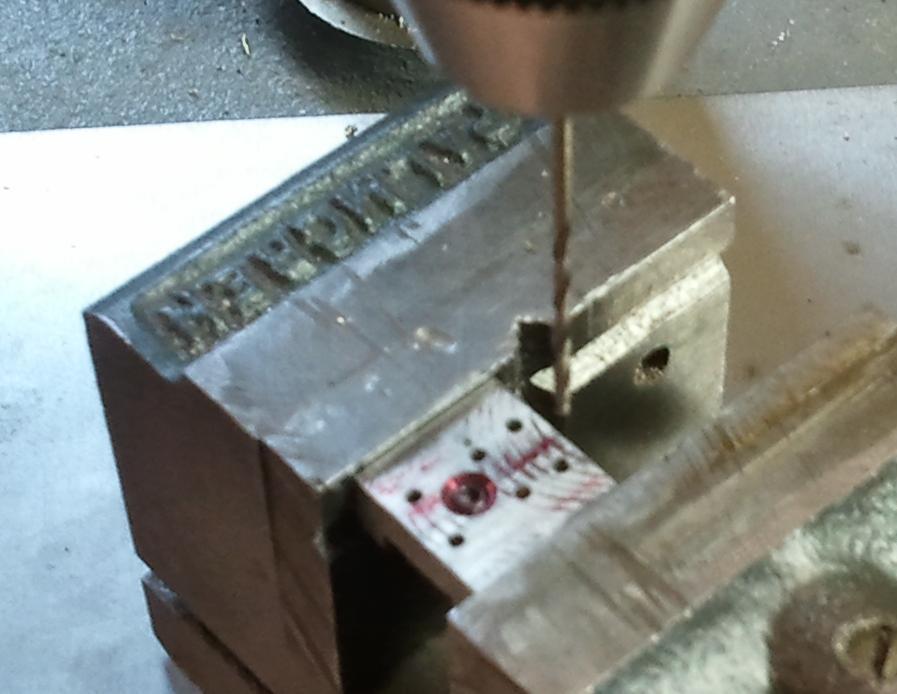

Here are the machine steps for the boiler pad clamps. The casting has a cored hole that is drilled to tap 0-80. Then it can be bolted the fixture shown in the center. The sprue is trimmed and the top is faced in the mill.

The final step is to drill the rest of the holes.

Here are the steps to machine the frame brace pads. They are for the smokebox brace. The sprue end was chucked up and a light cut to true up the spud was made. The part was reversed and the sprue/chucking piece was cut true and the back side of the flange faced. Light cuts with a sharp tool are the order of the day. And remember which way to turn the hand wheels I stuffed one with a senior moment.

The final lathe operation is to face the spud and tap it 1-72. Cut off the sprue and file the back was the final operation not shown.

The chucking piece I left on the smaller push pole pocket did not really center well with a scroll chuck so I chopped it off and used the 4 jaw chuck. I used the back edge of a tool holder to center the flat sides of the casting.

I set the hand wheels to zero after centering the first casting and it was simple to quickly set the other castings square for the machine work. I used a small end mill in the tailstock to cut the counter bore but as it starts on an angled surface slow feed is needed until it makes a full cut.

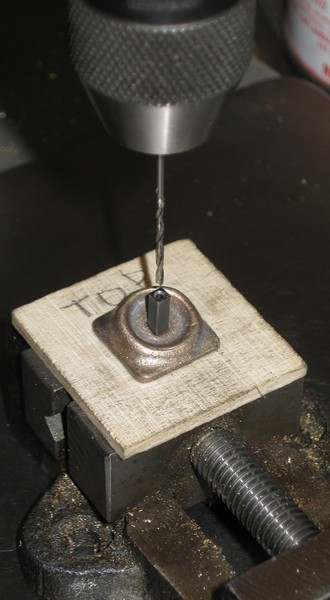

The old style push pole pocket has a square hole for a square head bolt. I used a section of the same steel square square stock that was used for a core and drilled a hole in the center. This was used as a drill guide to for the hole. I used a thin section of plywood and drilled for the sprue and the four pins on the back. The sprue extends past the plywood and is clamped in the vise.

Here is a shot of the new parts for both the Dulong and the Mapleton. I am missing one of the boiler pad clamps but I only intend to add the clamp that has a common rivet with one of the running board brackets. The other boiler pad clamps will be located when the boiler is installed.

Dan