This bit is purely for the tail stock ram. Different to most as fully back it only protrudes 2.6mm from front of casting ruling out the easier method of clamping round the ram.

Heres what we are dealing with and mock up of install.

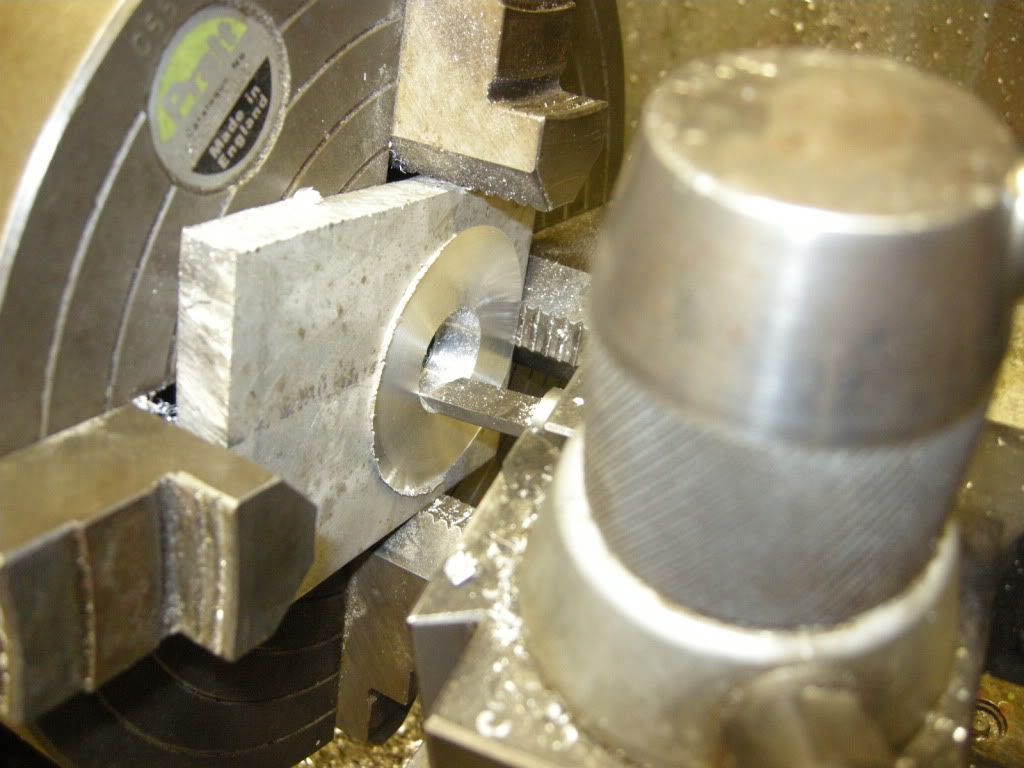

Couldnt be bothered to turn jaws round i still had clearance on carriage and top slide, just checking clearances. 11" chuck feel the wind as it rotates

Easy job drilling through 1/2" thick aluminium. Unknown grade but quite hard.

Easier to use boring bar to face off getting close to the lowest jaw.

Down to the nitty gritty i normally do this type of work quite often. If the aluminium was 6082 i wouldnt be going through in one pass with 5mm dia cutter and coolant. Thats still 12.7mm thick using FC3 disposable cutter in 8" rotary table and 5 1/4" 3 jaw chuck. Just get a feel for whats happening!

Done it differently here, dont know what come over me but thought i would try the mill readout out for PCD stuff. Also showing that superb three flute 3.3mm drill in MT3 collet.

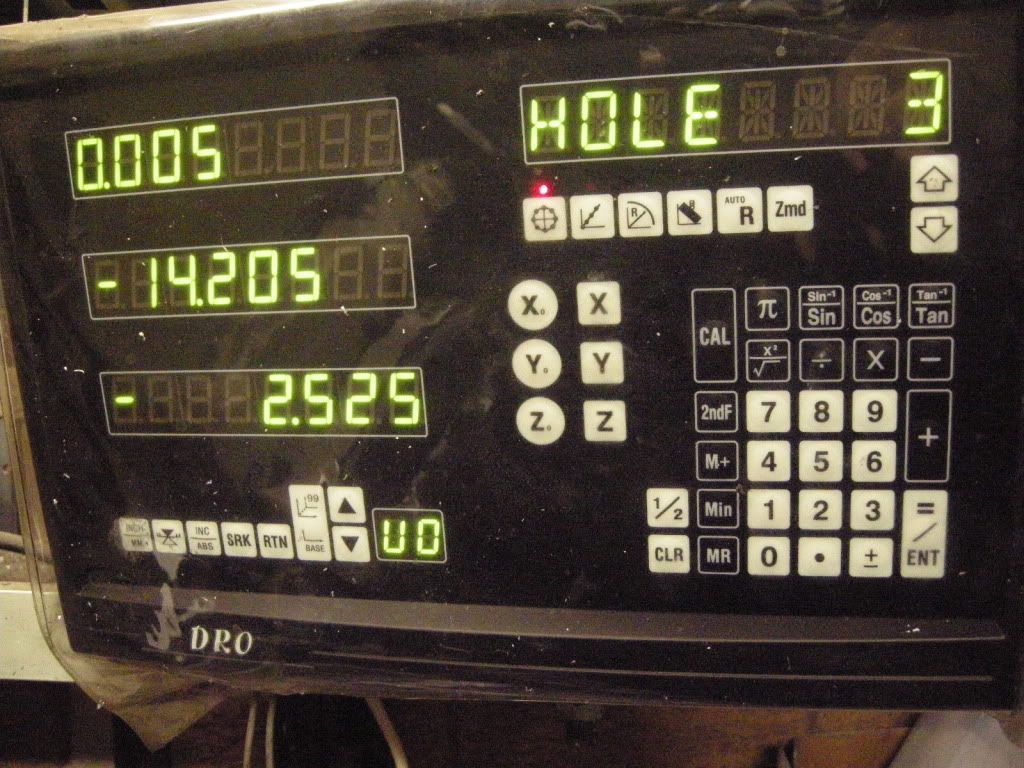

Never read the manual for readout but self explanatory in the programme to create PCD, just put in what you want. This is the cheap readout bought over three years ago and thought at time it was easier to use over all others.

All you have to do is press up and down to select next operation and bring into position so readout registers zero.

Patterned out with drilled 3.3mm holes countersunk pushed on to tail stock ram. Hand drill marked the locations with 3.3mm drill perfectly centres, thats why i didnt drill 4mm plus for screws at time.

Ram removed from tail stock and in 3 jaw chuck on rotary table. 3.3mm decent drill in 1/8" MT3 collet.

Finally tapping the tree M4x20 deep holes in ram.

From above i am totally amased how good these taps are. There are hard patches in the ram and only when hit them i had to back off like you would normally use a hand tap. Otherwise just ploughed straight in. Didnt have the bottle to power in when drilling them, if M6 and above yes.

Also shows the modded top slide to accept the Harrison 140 style of T. I have loads of tool posts all with multiple tools in each. I wouldnt have time to make 30 T2 QR tool posts as i hate having to put tools in to holders and centring for maybe 10 secs work.