Well.... I just spent about an hour writing a full blown post on my works and it got erased when my mum's computer decided to shut down IE8... POS!

So here we go again!

Thanks for the tips fellas, will look into them if my tech nerd fails (shouldn't do.) at least I have every picture and video saved on 2 external hard drives

Now, on to the mill....

First was to butcher a few of the brackets provided with the DROs....

In the instructions it has all sorts of jiggery pokery with a finger/dial gauge... I opted for a different approach, being so damn lazy!

My little Wixey digital angle meter. accurate to 0.1 of a degree will do me. (thanks for the batteries John

)

This approach will work just fine as it's set to zero on the mill table and then used to make sure the brackets are square to the table.

The rear mounting plate for the 2 part shield is fitted, the good thing about this is it is the mountig plate for the scales with the holes pre drilled and tapped.

So once it is in position the scales should be too... Checked with the wixey .... Spot on!

My mill foot is angled so I needed to set the bracket away at the top till it was plumb with the mill table.

Using the wixey on it's side it was zeroed on the mill table and then the plate moved out at the top till it read zero, making it the same. It needed an ~3mm gap at the top so 2 pieces of 1/8 HSS steel were employed as packers and once they were wriggled into position and all was tight it was checked again with the wixey.

This is actually plumb with the mill table!

Another bracket butchered and the drop bracket and spacer are created and fitted...

The rear scale is fitted in much the same way but I had to fab up a new bracket from scratch to fit around the oil nipples and

fit to existing holes since I couldn't get the drill in without removing the mill's column.... Erm, no chance!

Can we say "bodge it and scarper clamping method" ? Well doesn't everyone use a piece of 6mm threaded bar in a pinch

Fitted. ready for test (see above posts for that! )

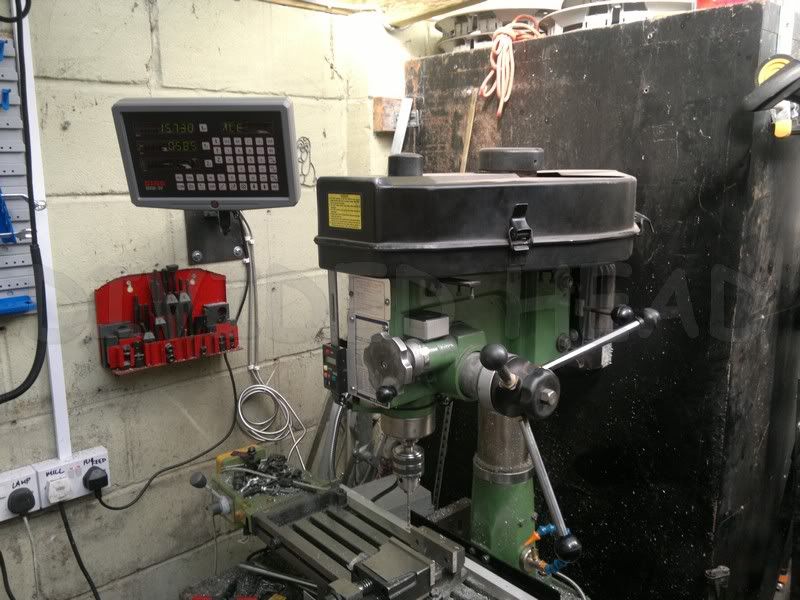

Last bit of fab'n'fit, the mounting of the head. There is absolutely no where on my mill to fit the mounting bracket.

so it's on the wall with it!

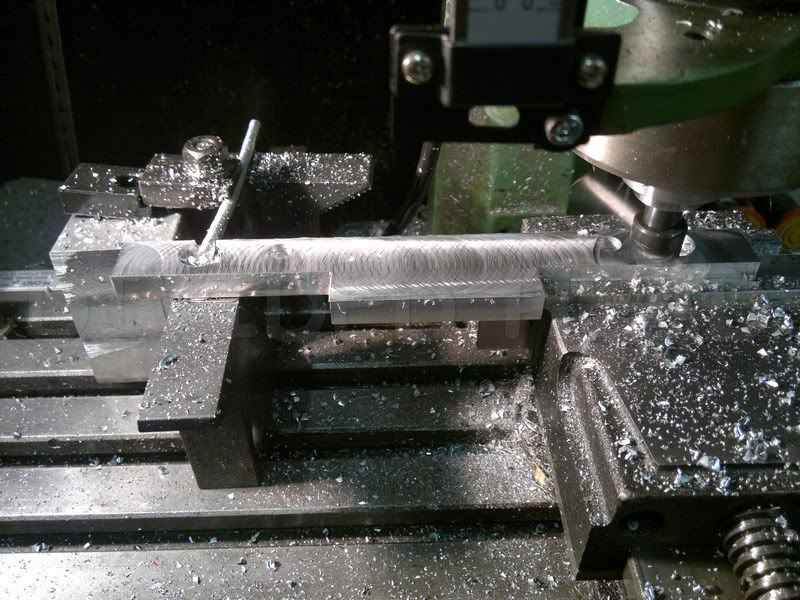

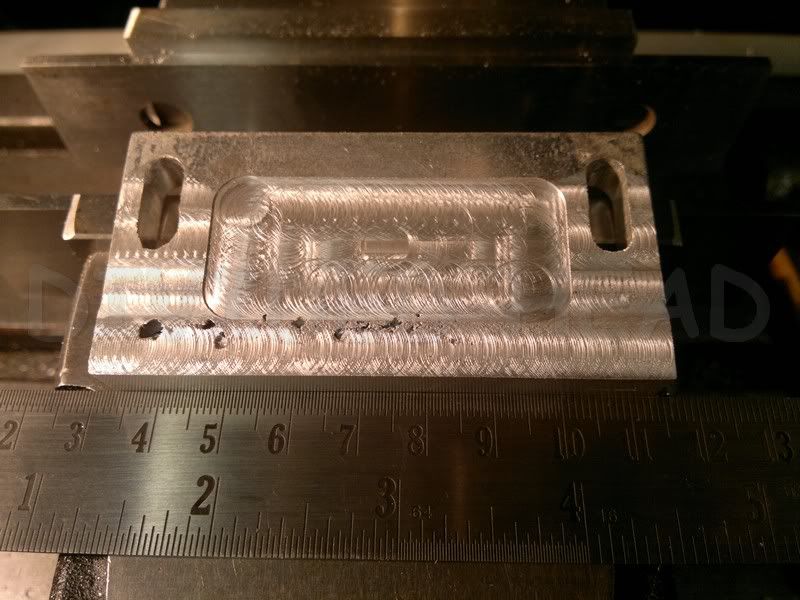

And my first attempt at programing. The pocket mill feature. Shallow as a test on a bit of the left over bracket they supplied.....worked a treat!

Well, that's it. Now for a bit of round tuit catch up...

Ralph.