I hear ya Dean.... shear lunacy.... friendly lunacy though.... generally a nice lot.... but the things we have to put up with.

Ok tonight. The weekend was a waste of time and nights have been filled so tonight (thursday night) was it....

Sooooo, what happened to the 'roll' I was on....??

I was going to achieve BIG things last weekend....

Well, reality happened actually....

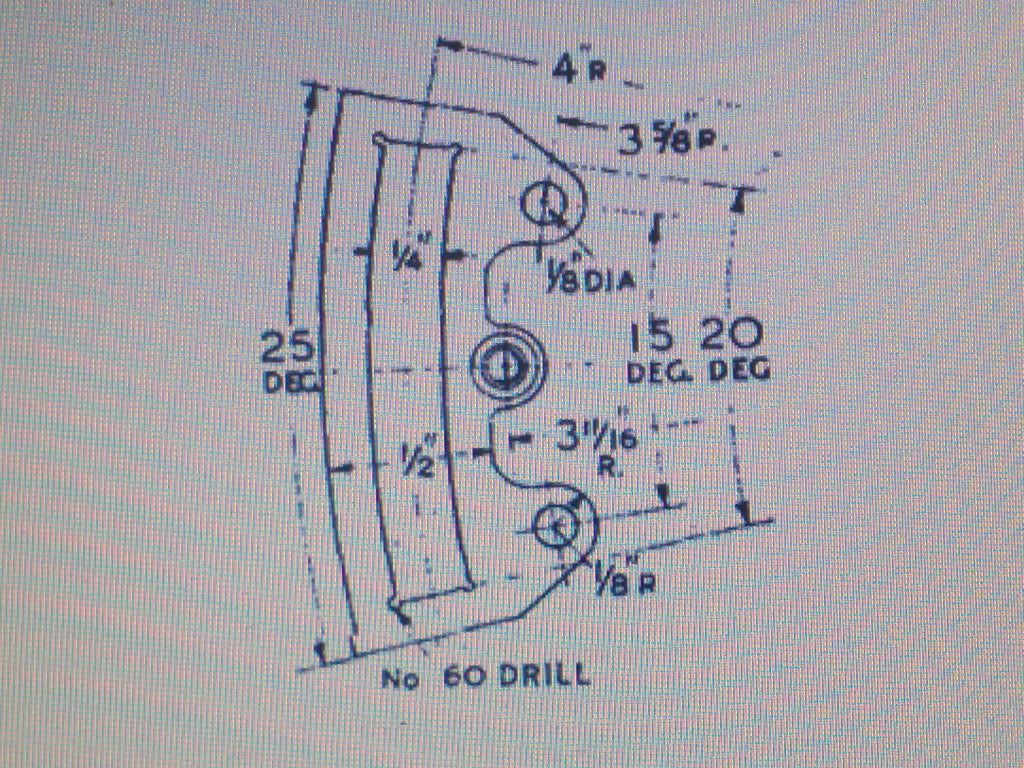

I was all set up to knock out a couple of these...

Simple enough huh? Looked like it to me ... had the plate all sized up re: thickness.....

If you take the time to think about it, this ISNT a simple part, radiuses/pivots etc... I followed Mr Westbury's example (to a degree) and found that rigidity wouldnt allow a smooth cut...

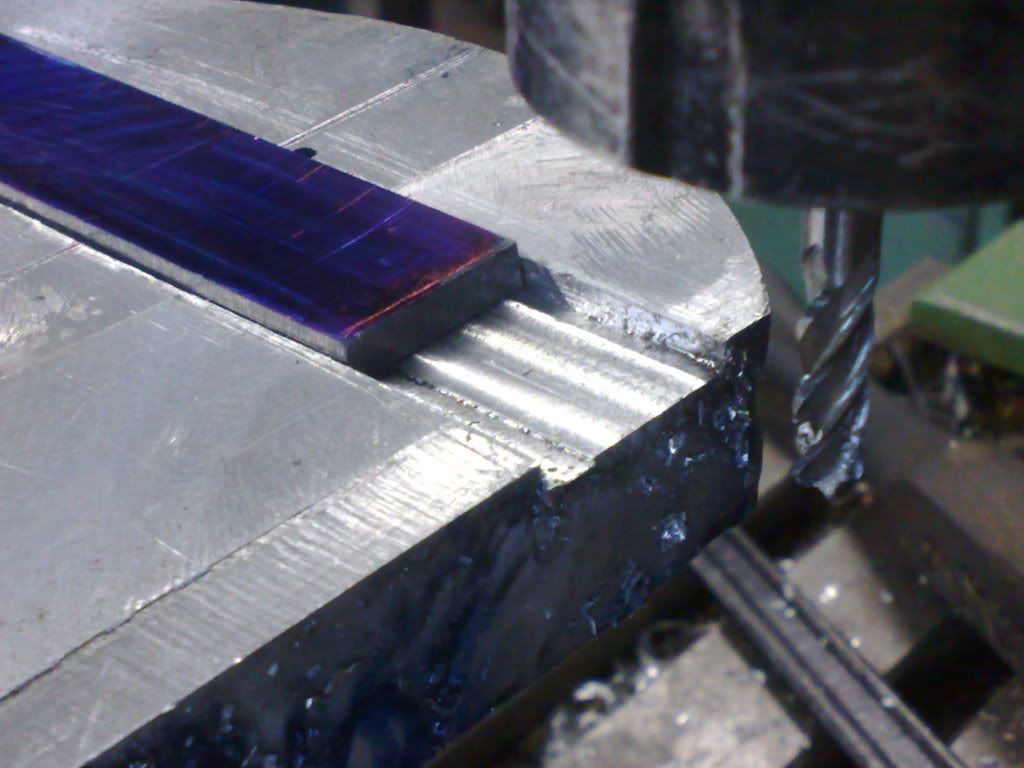

A Jig was needed! (as bloody always....) making the jig took 2 hours, making the first part took 15 mins.... damn this hobby IS an exercise in patience....

In this pic you can see the original 'aborted' attempt....

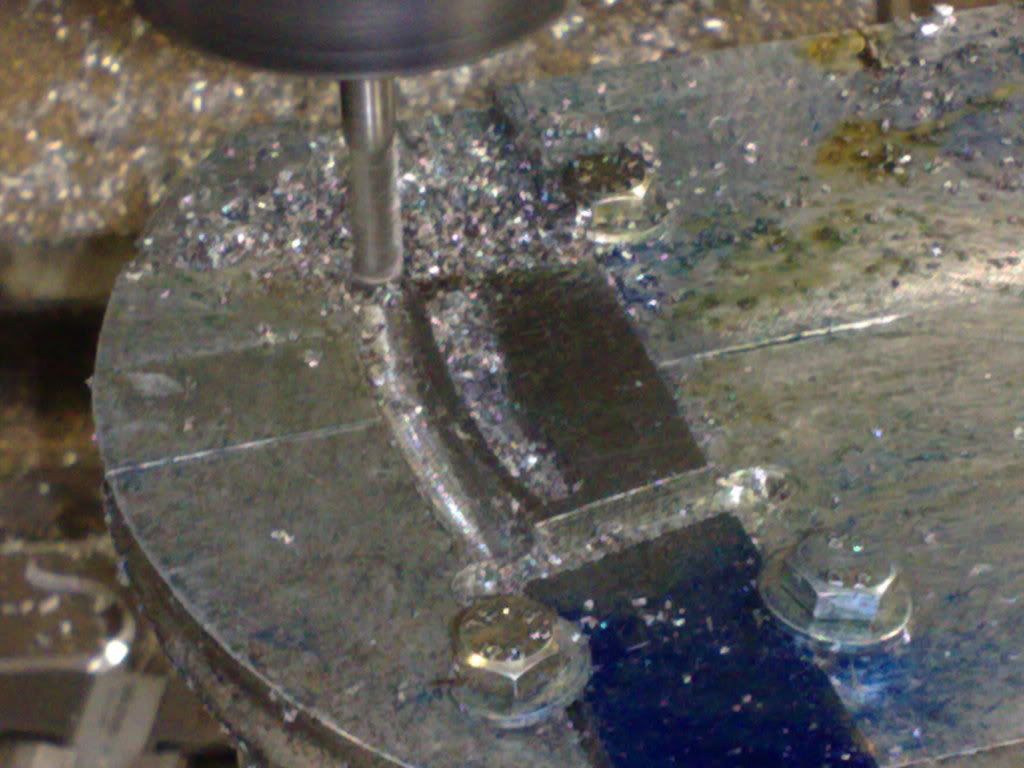

And then using the rotary table to make the raduius... worked a treat....

Machines turned off... time for a beer.....

BUT.... even with the DRO's, I made a miscalculation and ended up with the curved 'face' only 1.5mm thick when the plans call for 3mm. Will it carry the load? Well, I think it will with the plate being 5mm wide...

So do I remake the part? Or do I make another one the same for the pair that are needed?

Im thinking that it IS strong enough and intend to make another the same... thoughts are welcome at this point... (any point for that matter...).

And finally, I dont see why this needs the ends of the slot to be squared off, Ill make the slider with radiused ends to suit and it will do the same job...

Anyway, time to call it a night...

Cheers all.

Rob