Logically, now that the conrods almost finished its time to start the crankshaft. Im starting with the cheeks and this is bigger than you would think. Two storys here one is the crank, the other is recommissioning an old friend. More in a moment.

Firstly some 60mm stock was dragged out. No idea what steel it is... just steel. Machines and cuts ok. Trimmed the oxy end off.

Have I mentioned that I love the old power hacksaw?

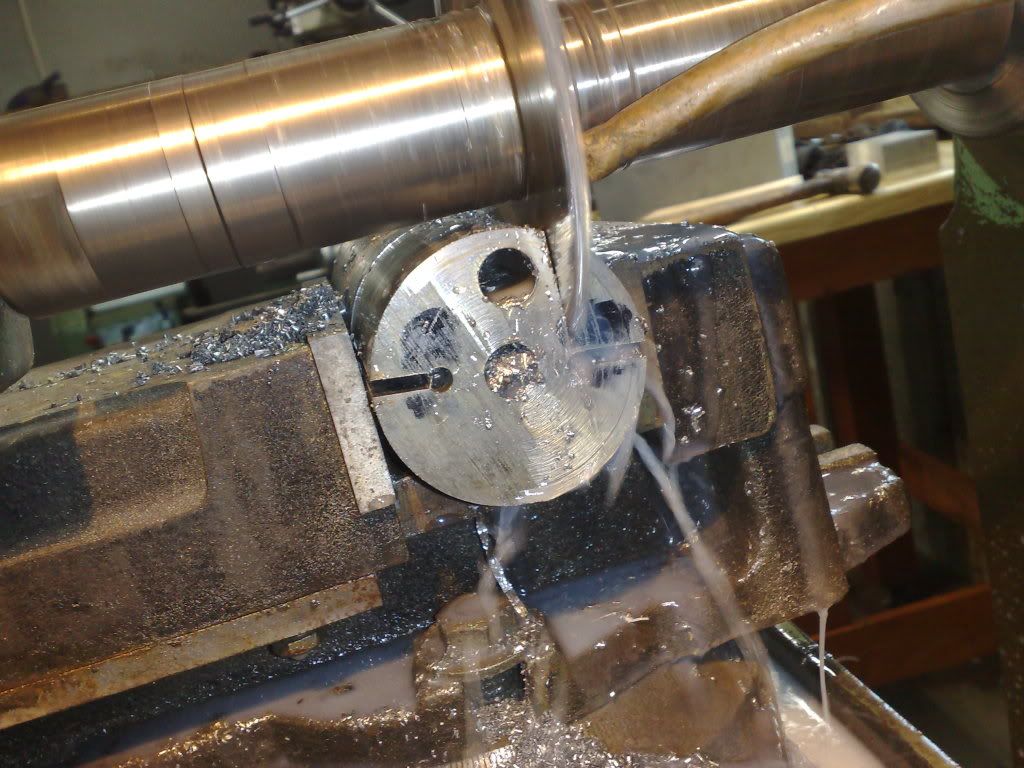

Trued up in the lathe and centre drilled, sized up and the drilled for full depth of 60mm using incrimental drill sizes 4 through to 12mm.

Marked up and drilled the big end journal and the radius of the cheeks as well.

By now the new table is covered in crap... as it should be...

Now the second story, the horizontal mill was put into storage about 15 years ago. The apprentice was using the pallet jack and ran it into the x axis feed handle completely smashing it off the machine. This was put aside for awhile until I got round to it. Eventually the broken parts were lost and then the machine was put into storage and pretty much considered to be scrap metal.

About a year ago I dragged an old box out from under a bench...bugger me the missing broken bits. Cept for the part which bolted to the table itself. I made a plate up, machined the gearbox to suit and had teh entire machine rewired... tonight was its first start up (the electrician finished as i was finishing drilling the holes)... away we went.... a momentus day for the old girl...

Slices into the steel like butter...

Rotate the shaft and cut the slight angles...

Cut across the shaft to free the slices and we have.....

Final sizing in the mill tomorrow and then slice the plates off in the power hacksaw...did I mention that I love this old machine?

This has saved an absolute heap of time and agro removing this metal with the mill. The mill is a big unit but still doesnt like cutting large chunks of steel.

More tomorrow..public holiday here...

Cheers

Rob