Hallo,

first of all I want to thank you for all the very kind replies.

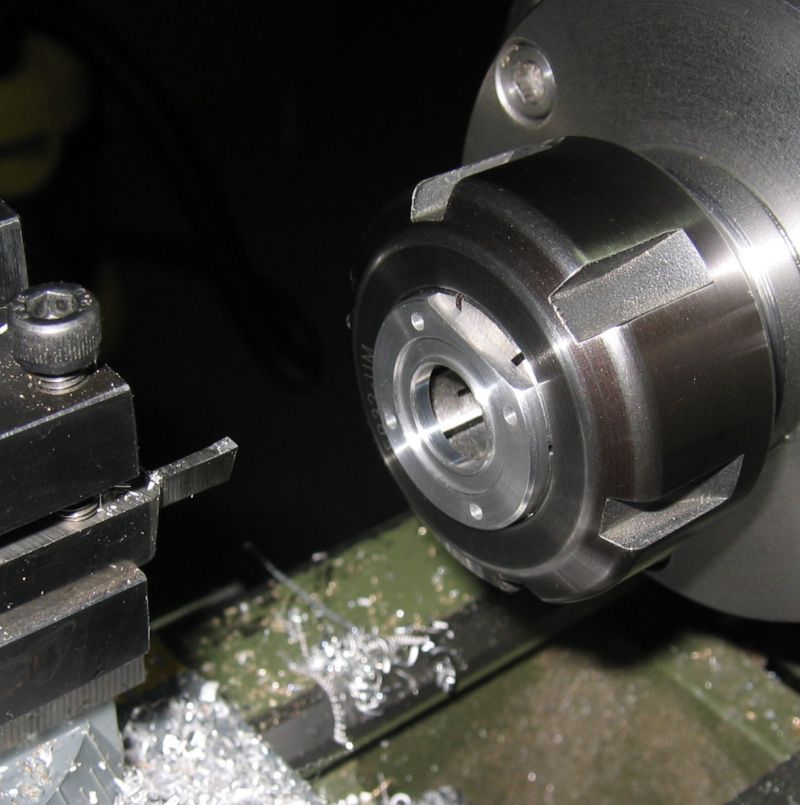

Today I planed to building the oil pump, but at first some pictures of the housing cover which will fix the crankshafts front bearing.

I like, if possible, to machine most of the components which get a mixture of turning and dividing operations directly on the bar and leave it in the collet chuck switching this from the lathe to the mill and backwards. That saves a lot of measuring and adjusting and offers me a much higher precision than shifting the things permanently from one chuck to another.

And then came the time for the oil pump. This little brass gears are modul 0.5 type with 12 teeth and had to get 2.985mm borings to press the 3.000mm axles (hardened dowel pins) in.

The assembly was done on the late, making the pressure with the tailstock spindle.

After the press fitting the hardened axels were brought to precise length using a little cut off wheel and a grinding disk on the frontal operation to do the last finish.

Changing the tool post grinder to the front side I grinded the flat area for the fixing screw of the crank arm which is later driven by the crankshaft.

Next came the main housing of the pump.

I had prepared four little bronze bearing bushes and glued them with Loctite in there bearing seats which I had drilled on the mill in the meantime.

After the facing operations on the glued in bushings I milled the two little anti cavitation drains with a 1mm cutter.

Next steps where the borings for the gear itself, going 0.1mm deeper than the gear height of 4mm. The aimed axel clearance of 0.03mm of the gears to the housing faces will be done later by fine facing the case surface on the lathe.

As all fits very well I could turn the main body to the precise diameter for the crankcase boring and cut the grooves for the oil routes and the 1mm viton seals.

And this will become the oil intake line.

And nearly the last thing to do is to part off the pump case from the bar.

So here the finished components

and how they are located in the engine.

And this is how the assembled front bearing cover looks like.

Now I am very curios if the pump will do its purpose well….okay….we will see…..

Good night from Germany,

Achim