Well, it's mostly been stripping, cleaning and painting so far (going with a black and brass colour scheme), though the last two videos show a new, simple and rather unique way to do brass plating at home with just a blow torch, drill and a brass wheel brush.

You are of course correct though and I will endeavour to post write ups and their accompanying pics as well as vids here from now on. Actually, small but significant progress suits written and pictured posting anyway so I hear ya and oblige ;)

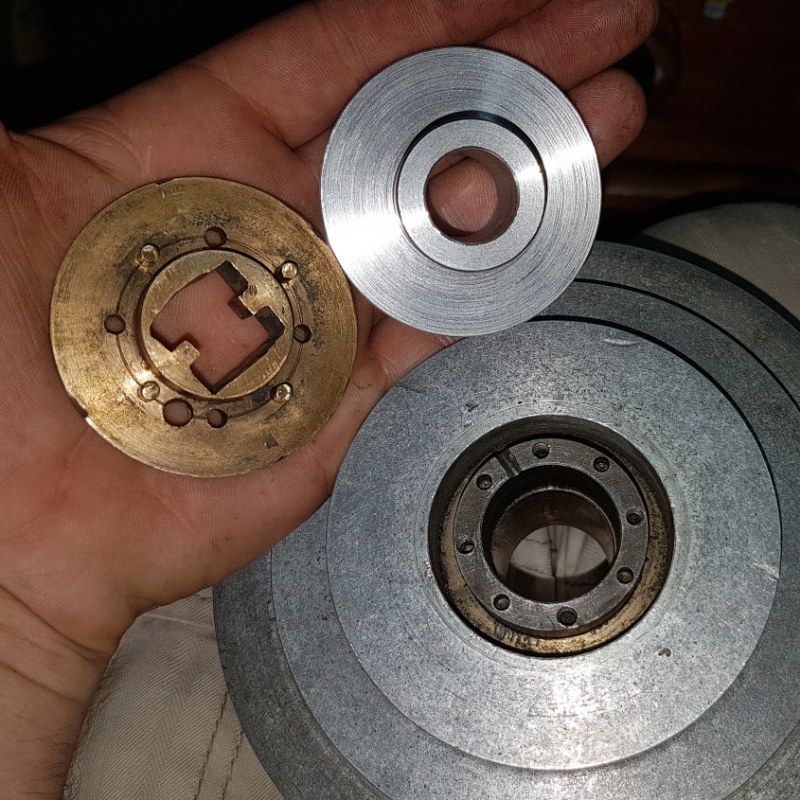

Thursday and Friday afternoon were spent making a replacement spindle drive plug blank:

The original plans call for a brass piece which is drilled and filed to include the keys that fit the slots either side of the spindle shaft. While the original design and method of the part's construction lends itself very well to even the most meagre of equipped home shops, I'm going to deviate and use actual key stock.

This part is actually quite involved and I'll need to finish making my keyway slotting attachment (made a start on the base and cut the radiused slot for the ram tube) and make transfer pins and screws to ensure the new holes line up with the pulley's geared drive tube in order to finish it.

My bearing grease arrived yesterday, so last night I installed the outer races of the new spindle bearings in preparation for full essembly (new ones are Timpkin tapered rollers, the last ones were single row deep groove and were well and truely trashed). However, I discovered that the replacements were undersize, so had to shim them for a press fit. I opted to put short lengths in three places per side as a wrap aroumd was proving somewhat troublesome for me:

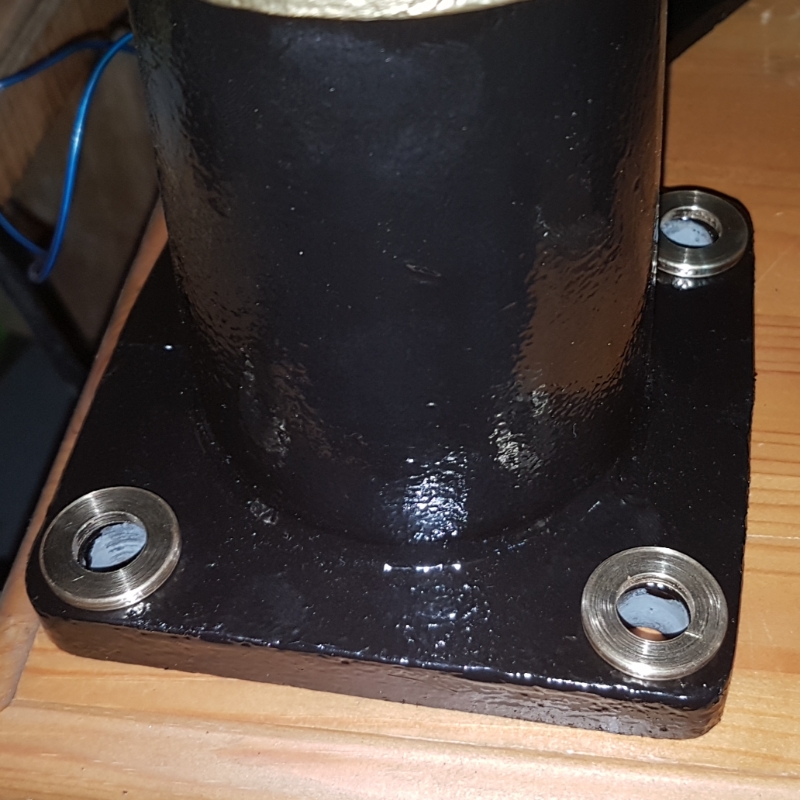

Today's small progress was making some .1/8" thick brass washers for the main column support casting bolts. In order to keep in with the colour scheme:

My next move is to heat black the bolt heads for the column support casting with boiled linseed oil, which will be featured in the next video, along with some footage of the above parts being made.