As I was rummaging through some of my old prints I happened on an early test project. This was probably made about 2yrs ago on a Rostock Max V1 printer. Best we could manage back then was 0.2mm layers.

The black print was the original and the white print I made a couple of days ago. The black was printed as one part with support that took hours to clean up, the model also required lots of superglue to fix where it delaminated as its all thin section from the arms outwards. The white print was done as two halves and then welded together, this one printed in 0.1mm layers and much stronger even the thin section arms, and once welded much stiffer.

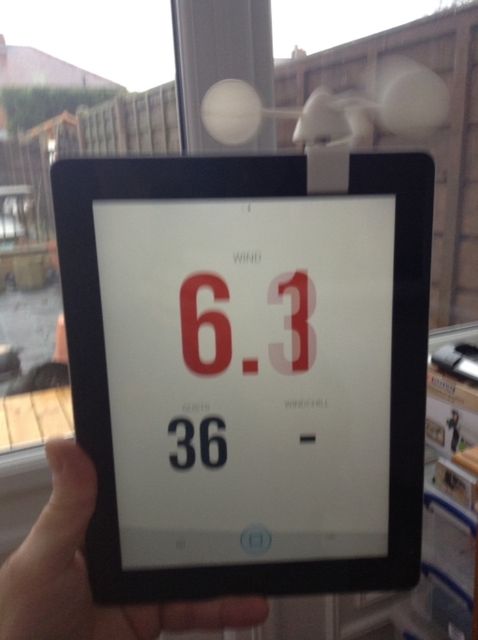

Fortunately I found an app that used a commercial built anemometer I was able to use with my own design.

Photo is a bit blurry as it's hard to blow and photograph at the same time. Now wouldn't this look cool nickel plated

Wonder who planted that idea.....