Hi Chris;

I think you've got good advice here, especially with Bogs' comments, (yes, all of them ; ).

I can offer my two bits, just for something else to think about. Since the bore for your cylinder goes all the way through, you can

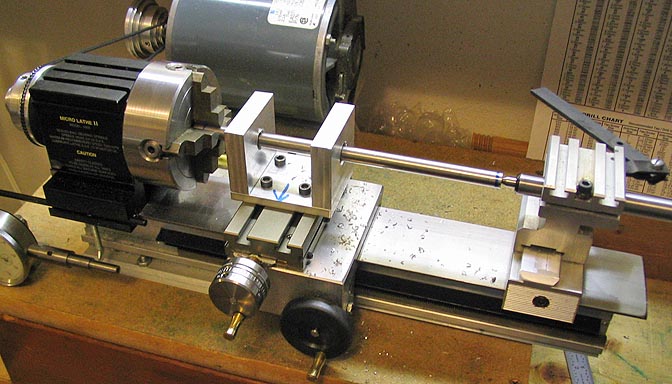

align bore it and have a very good chance of getting a true bore. The setup looks something like this:

A bar held between centers, which has a cutter held in a small hole somewhere near the middle of the bar.

Your work piece is first drilled undersized through the center, then mounted to the cross slide on the lathe, shimmed up as needed.

Just another way of skinning the cat.

I have to admit, piston rings are always something that have confused me despite seemingly being fundemental to most engines!!! I can`t quite understand what they offer over a good fitting piston directly in the cylinder!!

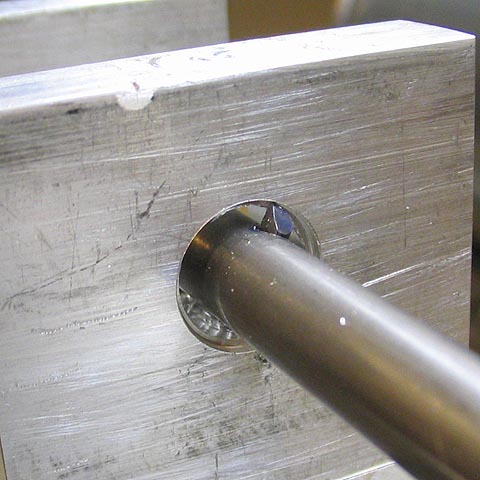

The piston rings do something the piston cannot do. They can run against the wall of the cylinder bore with no clearance tolerance.

The piston has to be smaller than the bore, of course, or it simply would not be able to enter it. Rings, being flexible, can run against

the bore doing the gas sealing chores for good compression in your engine.

They do other things, but being able to run right against the bore makes them a pretty handy thing.

Good luck with your build!

Dean