Hi Oz , thanks for that I have ordered them as think I will have trouble setting correctly without them.

This is the story of how the chuck was removed

I already had a boring bar I had made and a quick change tool holder that would hold it. The basic plan was to drill the end of this boring bar and make a parting tool incert to fit in the end of it that would align with the very rear edge of the backplate just short of where it mated with the spindle shoulder.

Thes shots of making the bar are in my mate Daves workshop, using hid Kerry AG lathe and Emco FB2 mill, cheers again Dave.

Centre drilling the bar

Drilling the bar for the incert to fit

The incert test fitted in the bar, this was something Dave had lying around so just needed altering as it was already roughly what we needed.

The side of the bar needed milled of for clearance and the other side was milled flat, drilled , tapped M6 and grub screws used to lock the incert in place

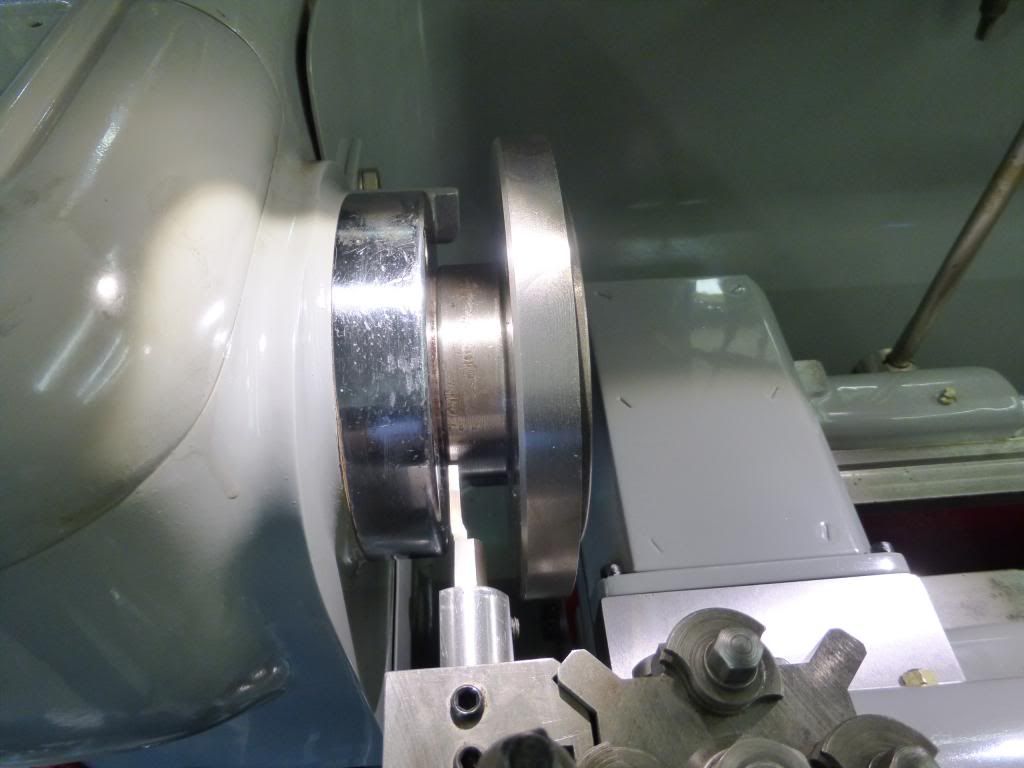

This is the new tool in the holder lined up for action

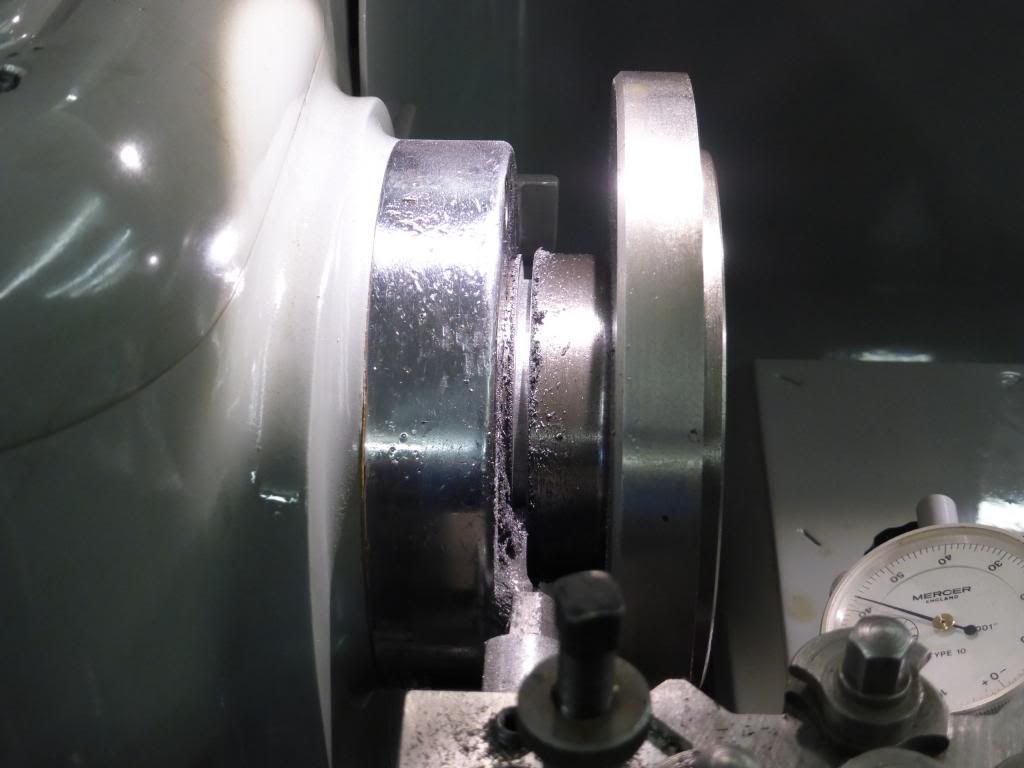

Note the DTI this was to gauge how far the tool advanced to make sure it did not mark the spindle

So far so good , just going slowly, once it was only a fracion to go, I tried putting bolts back through the backplate and the slightest of taps loosened the B*****d

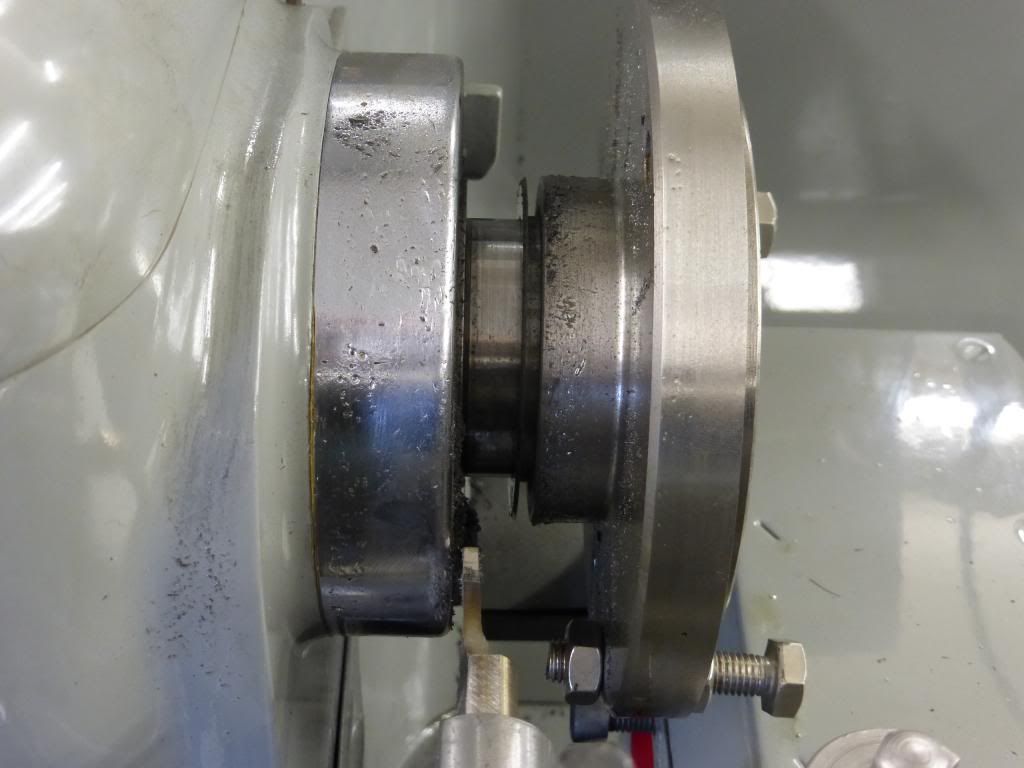

This is the backplate after its surgery, just as planned , the spindle not touched but the stress locking the thread releaved so free

The spindle survived the ordeal

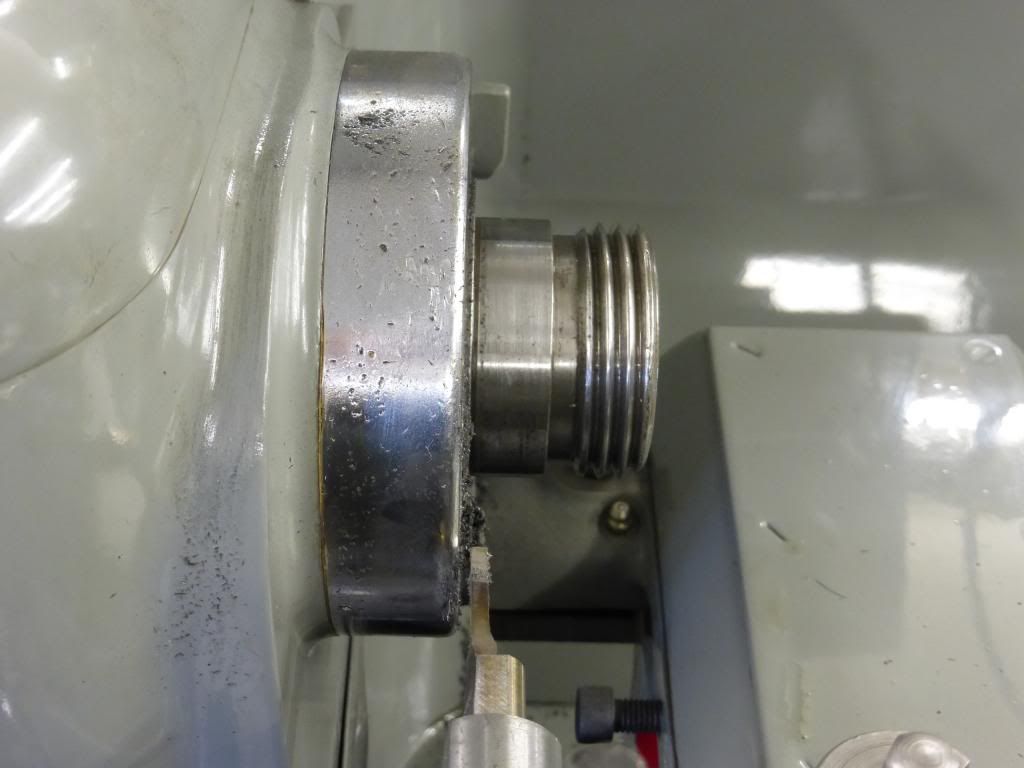

This it the blow hole in the casting that has been threaded, soon as I saw this I remembered it was like this before, it was like this when the chuck came with the lathe and has been used many times, do people think this is what will have caused the problem and is it savable by filling with metal putty and reshaping or bin it ? bearing in mind its either hassle or expensive to get a six inch backplate.

So at least someone else will be able to use this method to remove a locked on chuck without damage .........the back plate has enough 'meat' to be used again if its repairable too.

Cheers Mick