A little device I have been meaning to make for a while. I picked up a very cheap diamond stone on offer at the local hardware shop, it's not a bad size at 65mm x 150mm and double sided 800G+1200G and cost £10.00

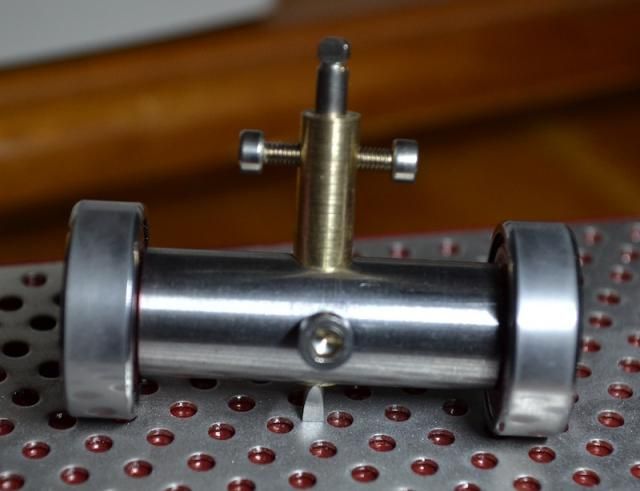

The bearings are for skateboard wheels, I picked up a pack of bearings really cheap and use them on all sorts of little projects. The fasteners are 3mm and two 2.5mm, just because thats what was in the odds and sods draw.

The setup above is for sharpening a jewellers screwdriver. The blade is carried in the brass sleeve and just set the blade pitch as you want it. Tighten it all up and a few passes on the stone gives a lovely finish. Flip the brass sleeve over and do the other side. If I grind the thread down on the 3mm screw I could just flip the whole jig over, a job for tomorrow.

Once the the blade is profiled remount the blade in the jig as shown above. Set the bearings on paper shim to set the blade length for grinding.

Hold the jig vertical and gentle grind for a very accurate blade tip. Just reshim to get your finished tip size.

This is about as good a photo as I could get of the finished blade tip, it measures 0.2mm and you can see from the reflection its pretty even. It took less than 5 mins to regrind this blade from scratch. The jig was made to sharpen gravers but it is turning out to be useful for other things too. For me not a bad days work making this and I'm very pleased to be able to make my own jewellers screwdrivers to accurate tolerance with a very cheap setup.

Joules