I can't claim credit for the idea but part 2 of my electrotrickery for my Seig SX3 mill is to add a power feed for it. Yes I know, you can buy a power feed attachment for it but my shop is so small, I would not be able to close the door if I used one of them. I was resigned to remain power feedless until I saw an idea that used a cordless drill motor and it just so happened that my Wife's 86 year old mother had won one in a raffle so with the necessary approvals, I broke the brand new seals on the box and stripped it down.

Some people leave the clutch on to protect against running out of travel and I was going to as well until I undid the wrong part of the chuck and ball bearings flew everywhere. Never mind, the Seig has provision for limit switches so it looks like I will be installing some. Most people who have used one of these let them stick out from the end of the table but this is not going to work in my case as once again, I won't be able to close the door.

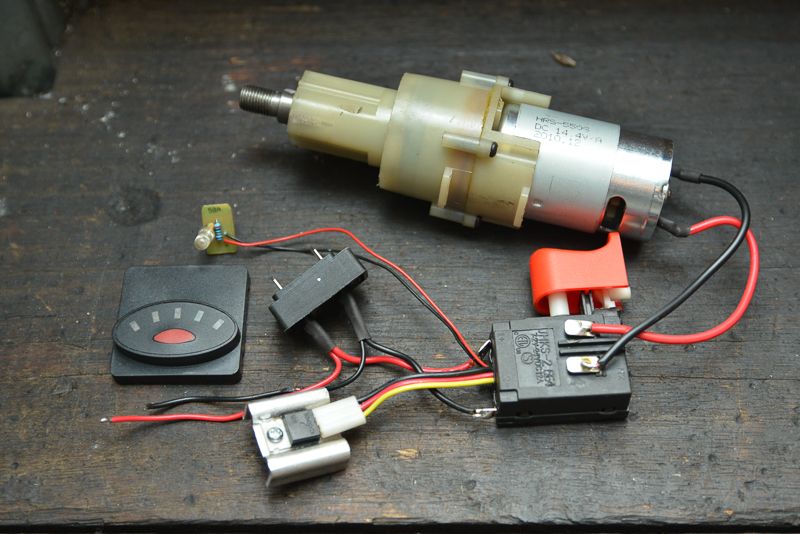

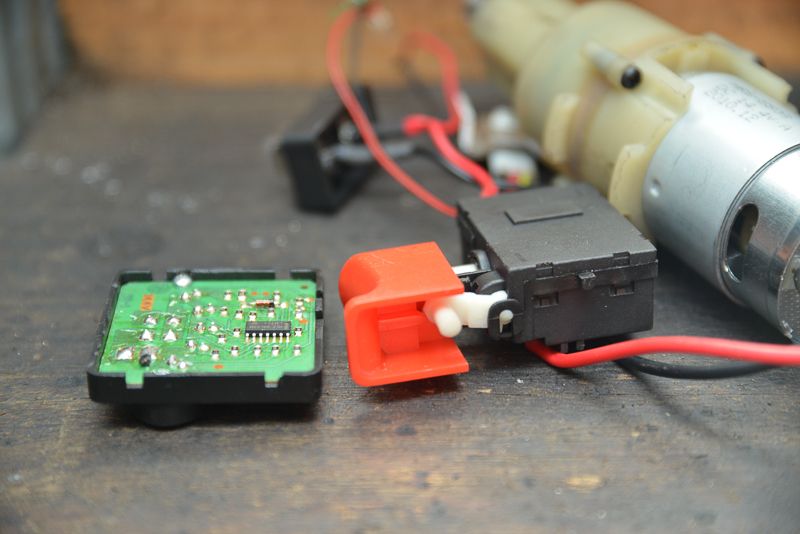

I thought about using the existing drilll controller and screwing in a bolt that pushed the trigger in as it had quite a range of speed control and did a bit of exploration work.

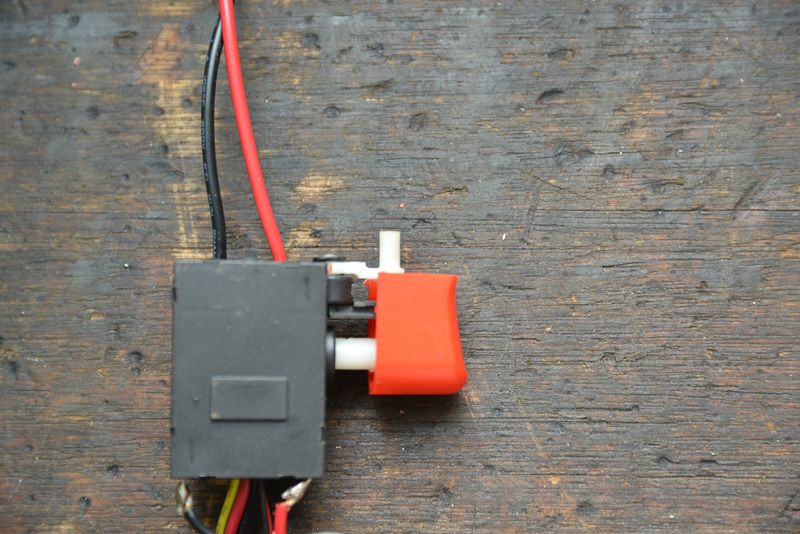

And got as far as cutting the top of the trigger off to gain access to the direction control

So now all I needed to do is to work out how to position the motor behind the mill table so I could shut the door!

I happened to have an electromagnetic clutch lying around.

This handy gadget lets the timing belt pulley freewheel until 24 volts is applied to the two wires and an electromagnet cicks in and the shaft is locked to the spindle automagically! So if the power feed is turned off, the power feed will automatically disengage and allow use of the hand wheels.

So the next step was to attach a drive tang to the shaft. I tried to remove the yoke from an old lovejoy coupling on it. It was pinned on with a fine pin I could not remove so I decided to use it to hold the shaft and be done with it.

I don't have that much room, so I trimmed the fingers on the yoke. There was nowhere much to hold it but I came up with a way

And before long, I had come up with a tanged shaft held on with a roll pin that fits nicely into the end of the Seig lead screw.

This is going to work out OK!

I had a matching timing belt made by Gates and another cog to suit but the belt is not long enough to clear the table. I took it to a bearing shop and they rang the Gates Aussie engineer and they could not match it with anything so resigned to the fact that I could not get the right length belt, I would resort to plan B.

I've got a flexible shaft that would allow misalignment between the motor and the drive cog but it really is too long as the motor will be well back along the table so it would probably require a separate mount.

Ideally, I would like to make the whole thing as a single L shaped fitting so it mounts to the end of the table in the two threaded holes Seig have allowed for this purpose. The clutch will only stick out about 80 mm which I can live with.

So a question for the experts. Could I cut the flexible shaft in half and silver solder it into a hole drilled in a piece of 12L14 steel? or brass? I've got a MAPP torch here and have done a bit of solver soldering copper pipe etc but was not sure it could be used for something like this. I don't know what material the shaft is made of. It is brass coloured but I doubt it is brass.