HI guys, I thought I take you for a tour of my shed. It will be short as it is only a tiny shed! 3.8x 2.4 metres actually. I built it myself 5-6 years ago

One good thing is that I have a separate garden shed behind my workshop to store everyday things like mowers and the like.

A while ago, we tidied up along the fence and I decided to put up a storage rack and pour a slab for an air compressor down the side. One day, I will have to get around to putting the roof on as the compressor went in yesterday.

Anyway, come inside. This is how i tlooked at the beginning of the year. It started off as being an ordinary shed with some shelves I put in as it was built but over time, I started moving things out to make room for my metal work stuff. First the push bikes, then the woodworking stuff but you know you have got the bug bad when you have to move out a perfectly good drill press to make way for a mill!

You can see the camping gear has stayed but I have a 200 amp MIG welder parked under a welding table I made. The bandsaw is on wheels so it can pull out for use and long stock can come in via the door. The red tool chest was a recent addition to help find a bit more storage.

Hmm, I must fix that wonky shelf...

Electric Diamond hone to keep the knives sharp, Grinder (which will get a linishing belt soon) and a very small work bench.

And my old lathe and an assortment of little storage drawers accumulated over the last 30 years sitting above it.

Then in January, I had a bit of a spending spree

Which took a bit of work to get into my shed at the other end of the house. But I got there

So now I have a Seig SX3 mill and a Hafco AL320G 13" lathe with 38mm spindle.

It was not long before I was doing stuff

And before long I had a BXA tool post fitted

and a carriage lock which has saved me heaps of time. I have a straight shaft bare micrometer on order so I will probably redo this so I have precise control of the stop position.

I was a bit annoyed that the oil sight glass broke twice, once before I got the lathe installed

For starters, I swiped a bung out of the mill table for coolant return but I eventually tracked down a metal framed sight glass.

I also made up a dial indicator holder which has yet to be used as with the bigger lathe, I have not had to resort to the 4 jaw yet.

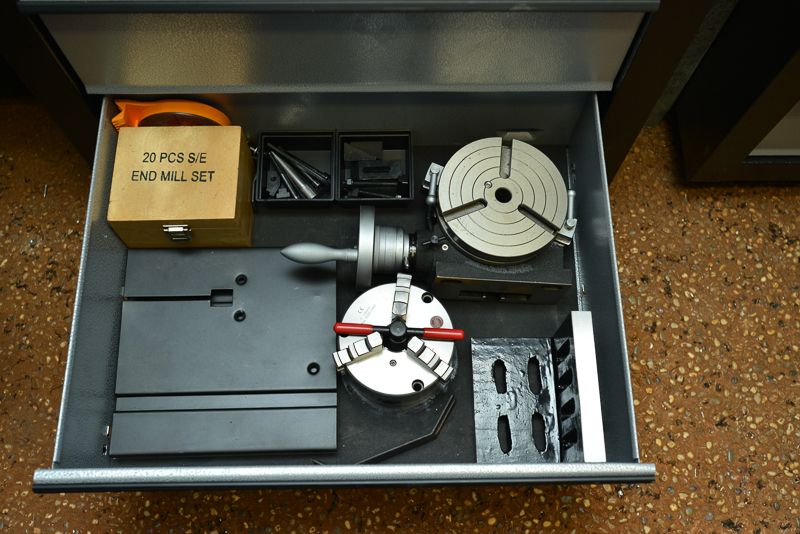

I then found out about 5C collets, so I grabbed a collet block and a collet chuck adapter for the lathe. Somebody gave me a few he had spare which I have yet to use but I have a full set of metric and imperial ones on order.

I wish I had them over the weekend for one job!

I was getting some laser cutting done and I did my first CAD job to get a couple of band saw tables made up out of 5mm plate, one for me and one for the generous collet donor. All I had to do was counter sink two holes

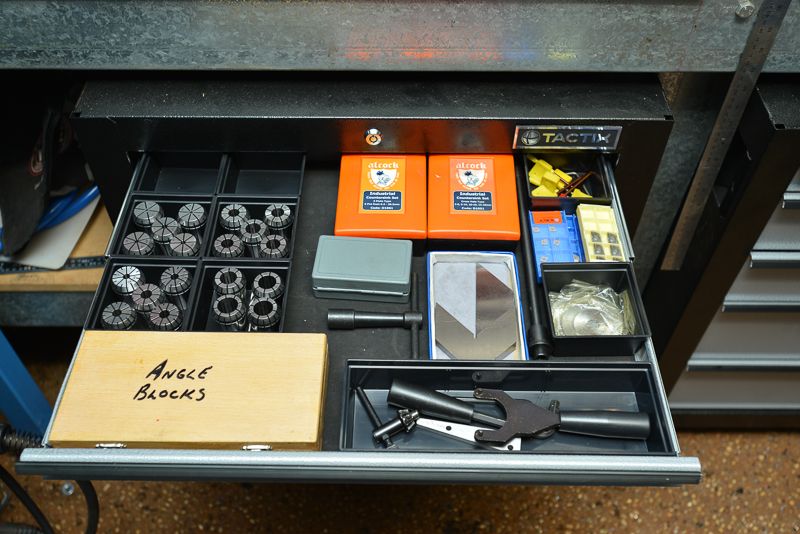

So by about now, I was running out of room, QCTP holder were breeding like flies

and stuff was everywhere. I decided the tooling accumulation had to stop for a while while I addressed a storage makeover. I started off with buying some shelving units for the garden shed and after a big cleanup out there, I moved some stuff out of my shop into our shed. Then I grabbed a parts drawer which looked interesting

And someone told me about Raaco storage cabinets. I ordered 5, one got damaged in transit so they sent me a replacement, with a couple of pop rivets and some gentle panel beating, I repaired the bent one.

It looks like now I started the bottom row, I have room for one more. I deliberately left a bit of a gap at the tailstock end and have the material here to make a timber shelving unit for QCTP holders.

I also grabbed a couple of pretty cheap drawer units that were low enough to fit under the benches and I hacked out some of the bottom shelf and screwed them onto the shed frame so they won't tip. Now things are a bit more organised.

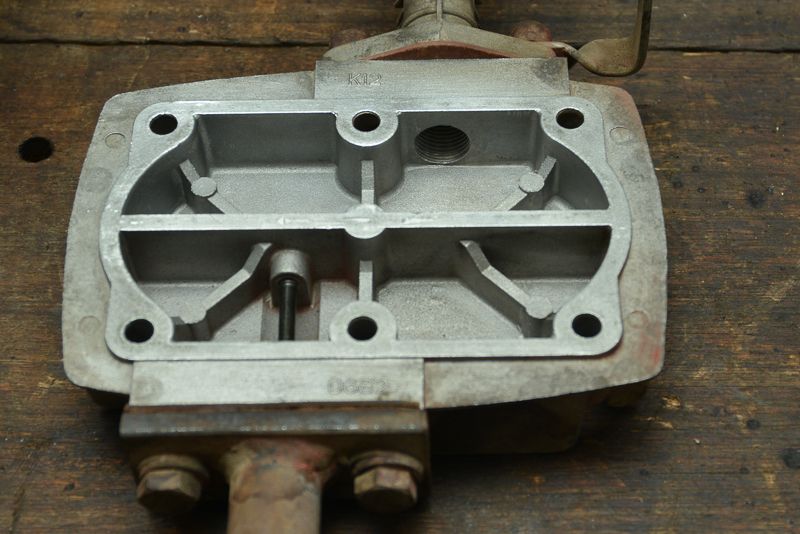

So we are nearly up to date with where I am in my shed project. But I got distracted and bought a compressor at an online auction based on this photo.

These are a very good Aussie brand with an Italian pump. Today's price is about $1100. I ended up winning it and took it home. I found it needed a new motor so I stripped the head off it to check it out. Somebody had been in there before me and had the pistons out, I assumed the rings had been done so did not dig any deeper.

and checked the valves

I cleaned it up, replaced the air filter, oil breather and head gaskets and gave it a coat of paint over the weekend and it is now as good as new sitting on that bare slab of concrete in the second photo. I took some pics but I have not had time to get them up on Photobucket.

So in amongst all of this activity I have spent about 8-10 days painting the house inside and out. It still not finished and I want to get it done so I can get rid of all the clutter and put things away where they belong.

Anyway, I will post an update once I get the photos off my camera.

Cheers

Rod