Yet another project has kept me away from rebuilding my Harrison L5 lathe , this time it was to make a safety rail and gate in alloy to match an existing bit of rail that goes around some floating jetty type walkway in a marina. I am no expert at alloy welding but my friend was stuck for getting it done so I said I would give it a go.

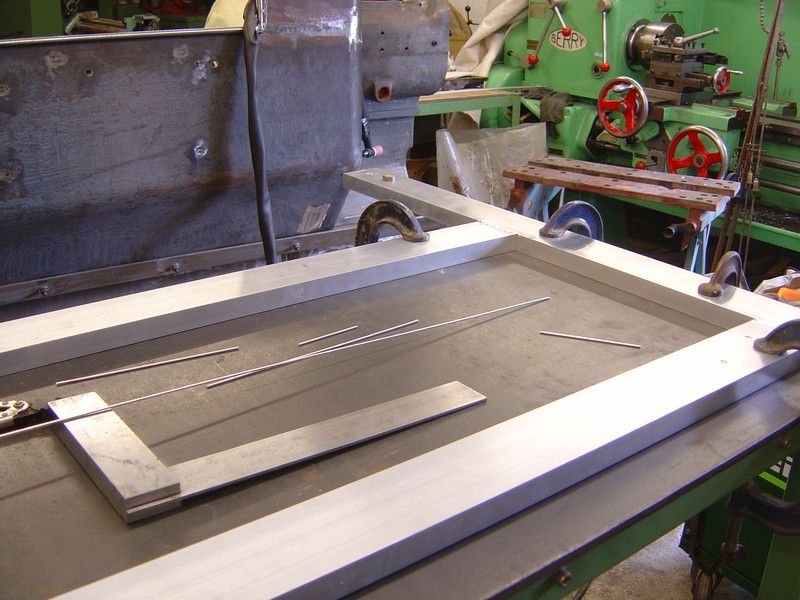

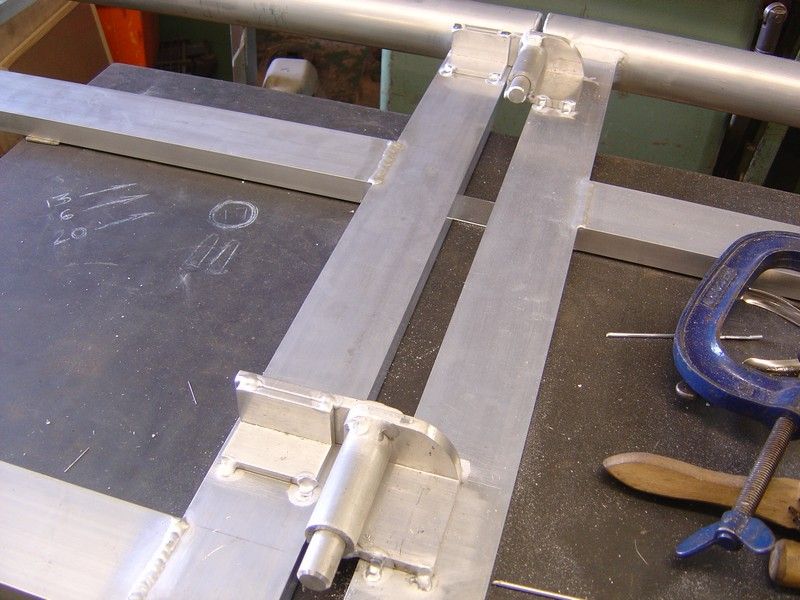

This is the basic job laid out after being cut to size, the closest bit of frame is the old original part , no matching handrail could be found so the round tube had to be used to do the new section with, of course everything had be measured from the bottom of the old handrail so all had to be laid out to get thing to line up to look as matching as they could.

I had to dig the welding table out , which involved moving allsorts of stuff into my way for the next job lol. I clamped everything down square and welded one side , the frame was bigger than the table so was more hassle than it looks here.

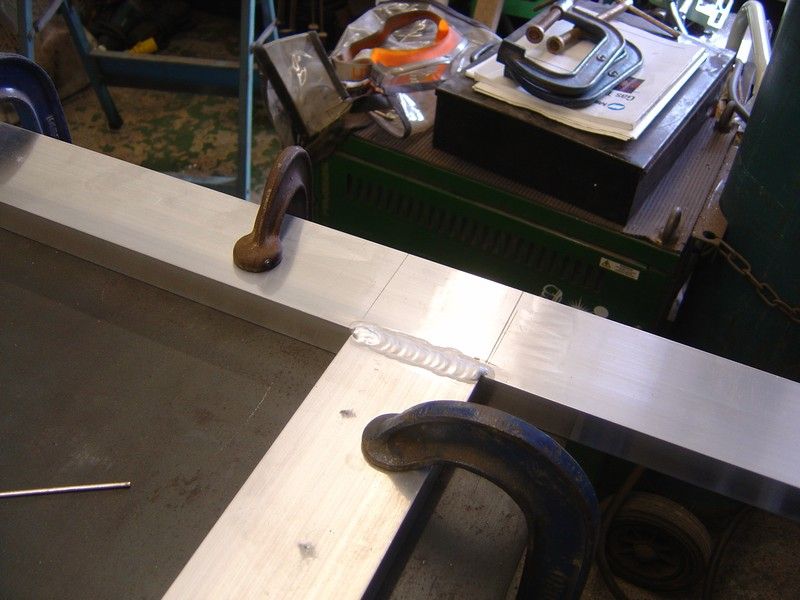

It was welding ok, Could be better mind! The material is about 3mm (1/8th inch) thick I am using 3.2mm rods and about 130 amps AC .

This is the frame welded up after much hassle , swearing and moving almost all the stuff in the way several times as well as the welder tripping the breaker a good few times, I made round discs that were a tight fit into the handrail and welded around to blank them off. I now had to figure out how to hinge the gate part , not as easy as you would think with the handrail being wider than the uprights etc.

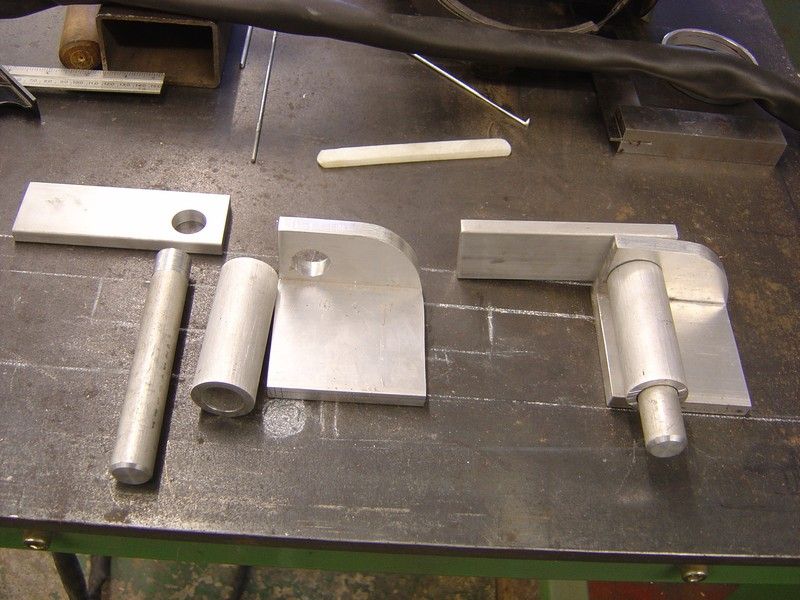

This is what I came up with for the hinges , it was Apollo 13 style , they had to made out of what was lying about so this was my best option, nice big chunky jobs , that even a fat bloke can lean on and not bend while shirking work

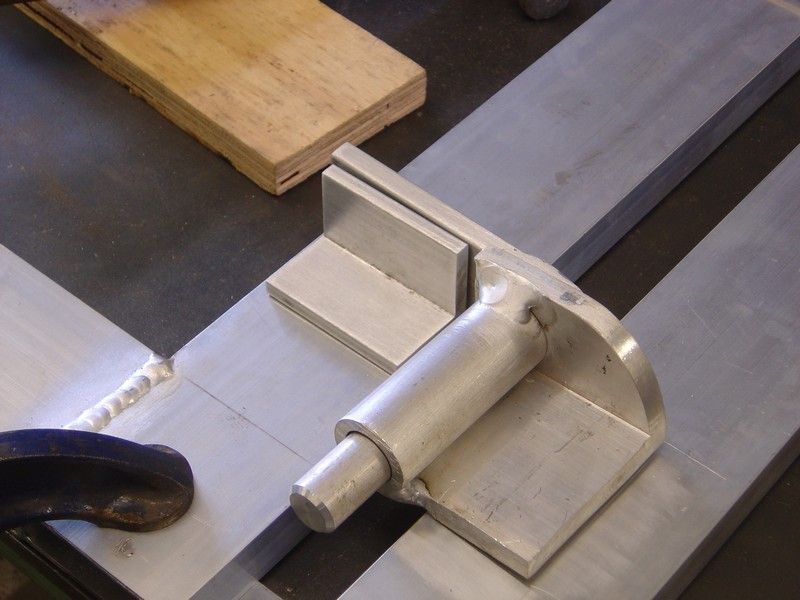

To make things easier to line up while welding I decided to add the bits of angle under the pin sides of the hinges

After much clamping and checking , hinges tacked up and tested to double check that nothing catching at either end of the gate.

This shot shows the general shambles I am working in , no room to get around with ease and welding at the wrong angles and stretching across etc buts thats just how it is when every project is nothing like the last lol. Also half the mess is what has been mover to make room for the welding table and the frame to then clamp to it.

The finished job , its still quite light to carry , the gate has had the top hinge welded at a height that it will foul the handrail so can not be lifted off , as metal things have a habit of walking these days

The welds look ok when you look at the overall thing , I know they could be better, I ended up starting with a 2.6mm tungsten, then wanted to go to 3.2mm but I had a faulty gas lense so had to go up to I think 5mm but could not crank the amps up more as tripping the house breaker so not idea really but did do the job.

This is the hinge set up welded, no way these babies are falling off thats for sure !

The gate swung open, I double checked that there was no crossed wires to which way it had to swing and what side it pivoted on before welding anything ........ its happened before lol

Right as usual I will end with saying , it really is the lathe now lol.

Cheers Mick.