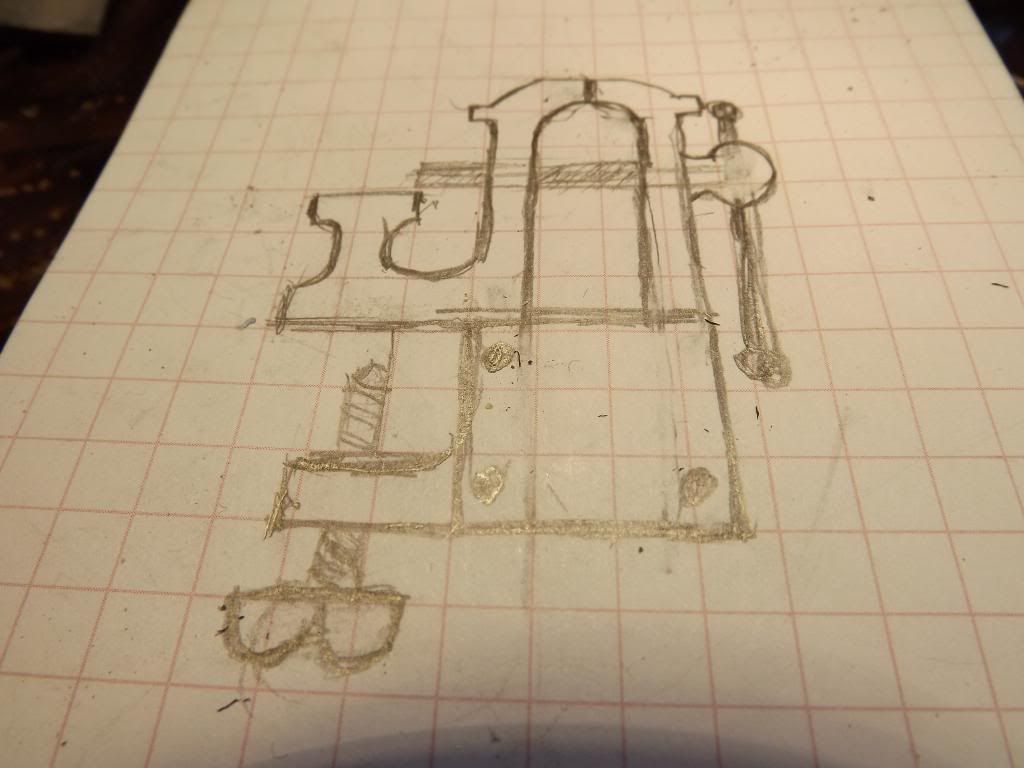

Hi, Anthony. Yes, these table vises are very functional. I use mine daily in my hobby work, and I collect them - when I can find any. They do look antiqueish, and I think that some of mine really are. Any way, I like the looks of them, and since my hobby is building miniature tools, I just had to try and build one. I've had this in mind for quite some time and finally just jumped in and have a good start. It will be 2/3 the size of my smallest and should be 2 1/4 inches tall. Ralph

I can visualize it.

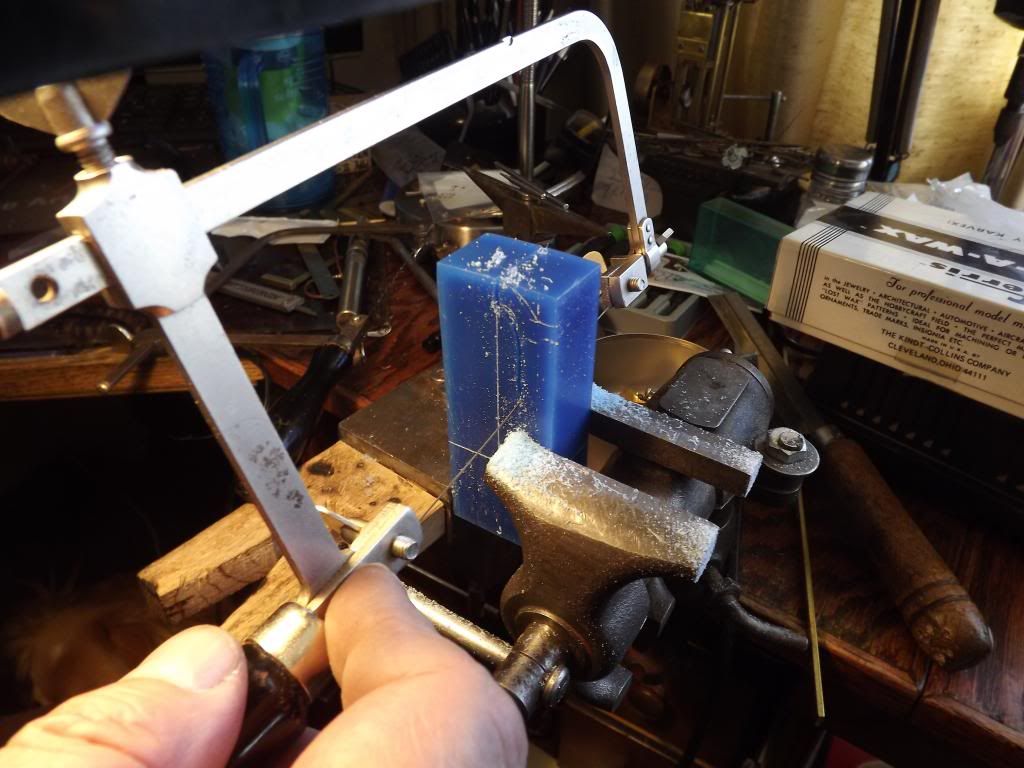

From a solid hard wax block, a close approximation was cut

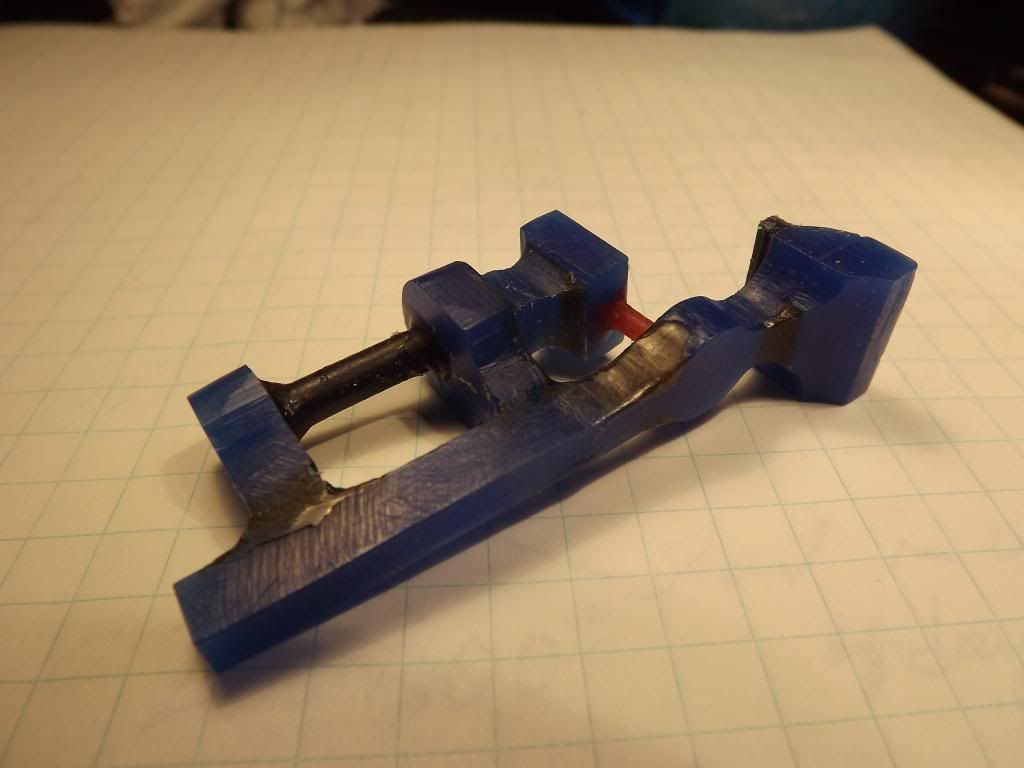

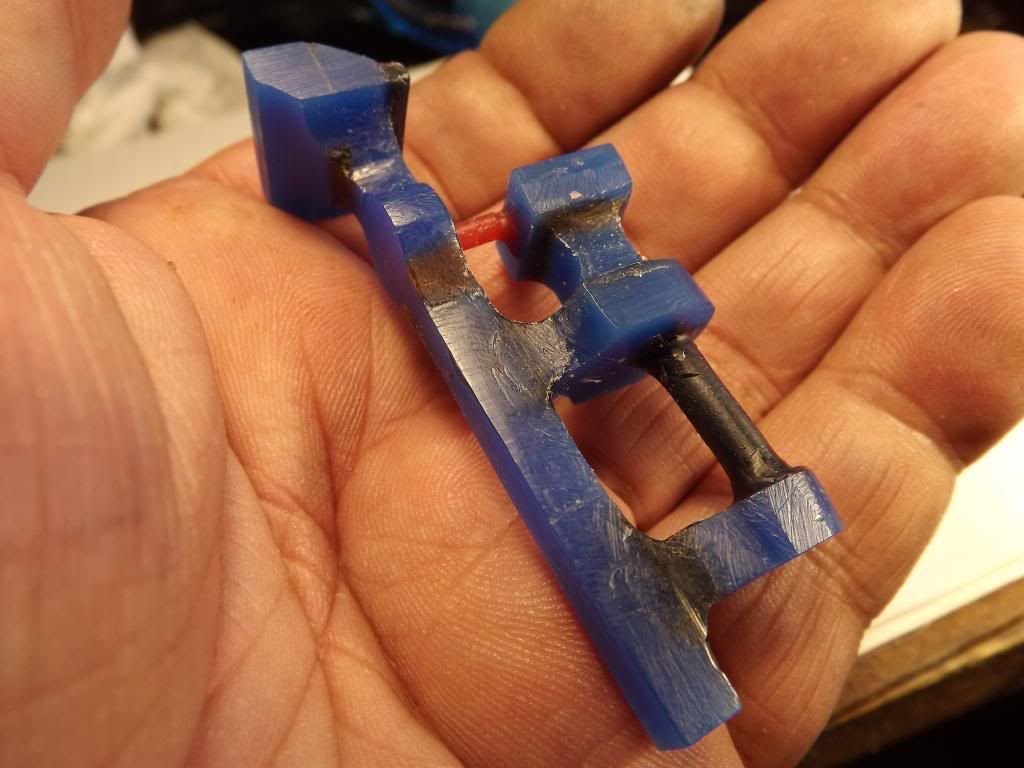

Then, as Michelangelo once replied when asked how he could sculpt such a fine elephant out of a block of marble, " All that needs to be done is to remove from the block everything that doesn't look like an elephant." I'm no Michelangelo, but I think that I know what a table vise looks like, and removed from the block of wax all the parts that didn't look like one and added flow channels and cosmetic touches.

There are many procedures to be sequentially followed. I plan to cast a solid metal master pattern from which a master rubber mold will be made to produce identical wax copies - the front and rear jaws are very similar. etc., etc.