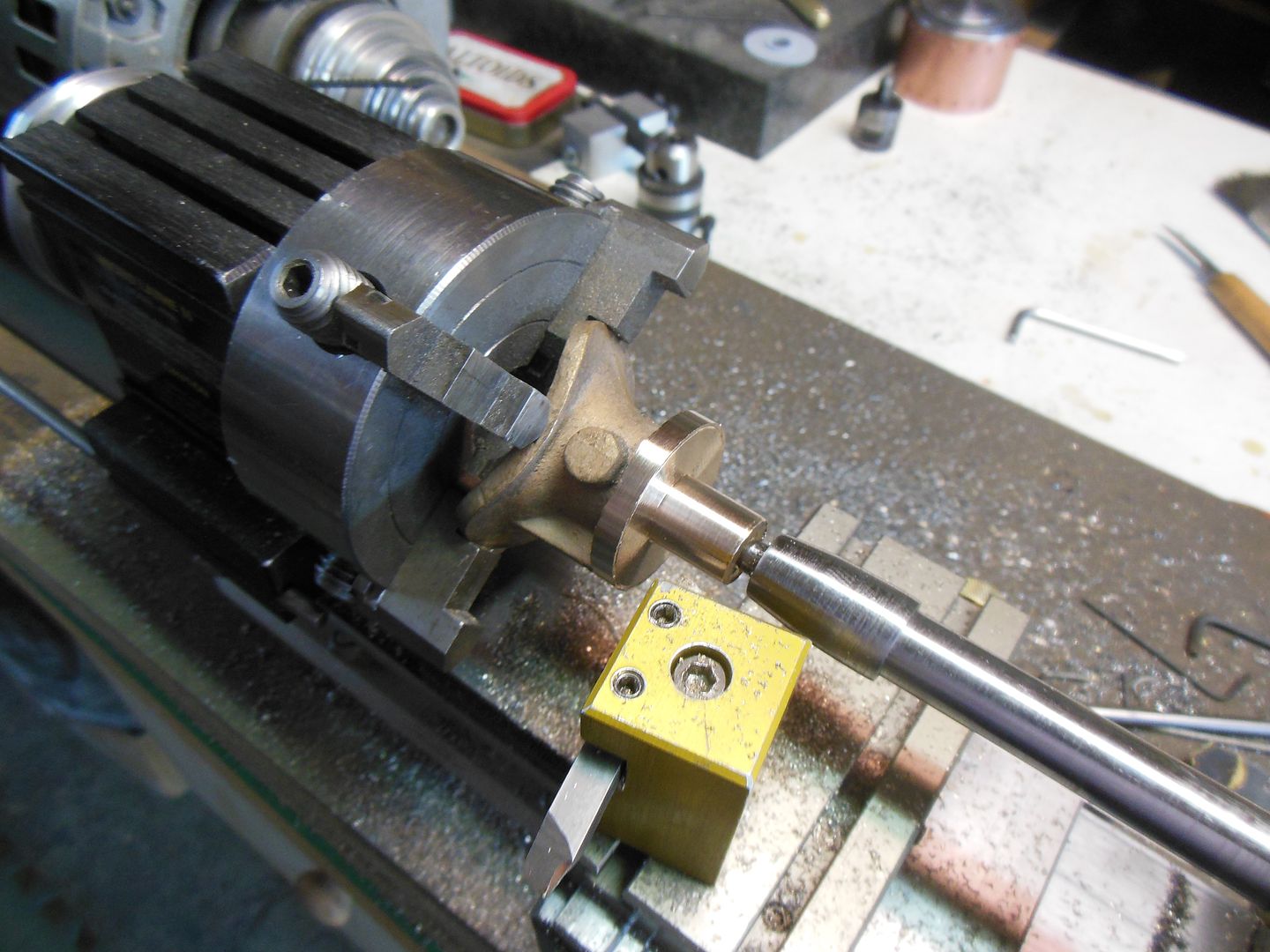

Started machining the casting for the smokebox saddle, fussed around and got it running more or less true to turn the

chucking spigot

set it up in the mill to shape the curved surface with the boring head

put it back in the lathe to bore through, and then drilled a steam passage up from underneath, that meets a hole in from the face

of the web on the side of the casting. Here you see the nice plug silver soldered into place on the back of that web since I got a little enthusiastic and drilled right through instead of just meeting the passage up from the bottom.....

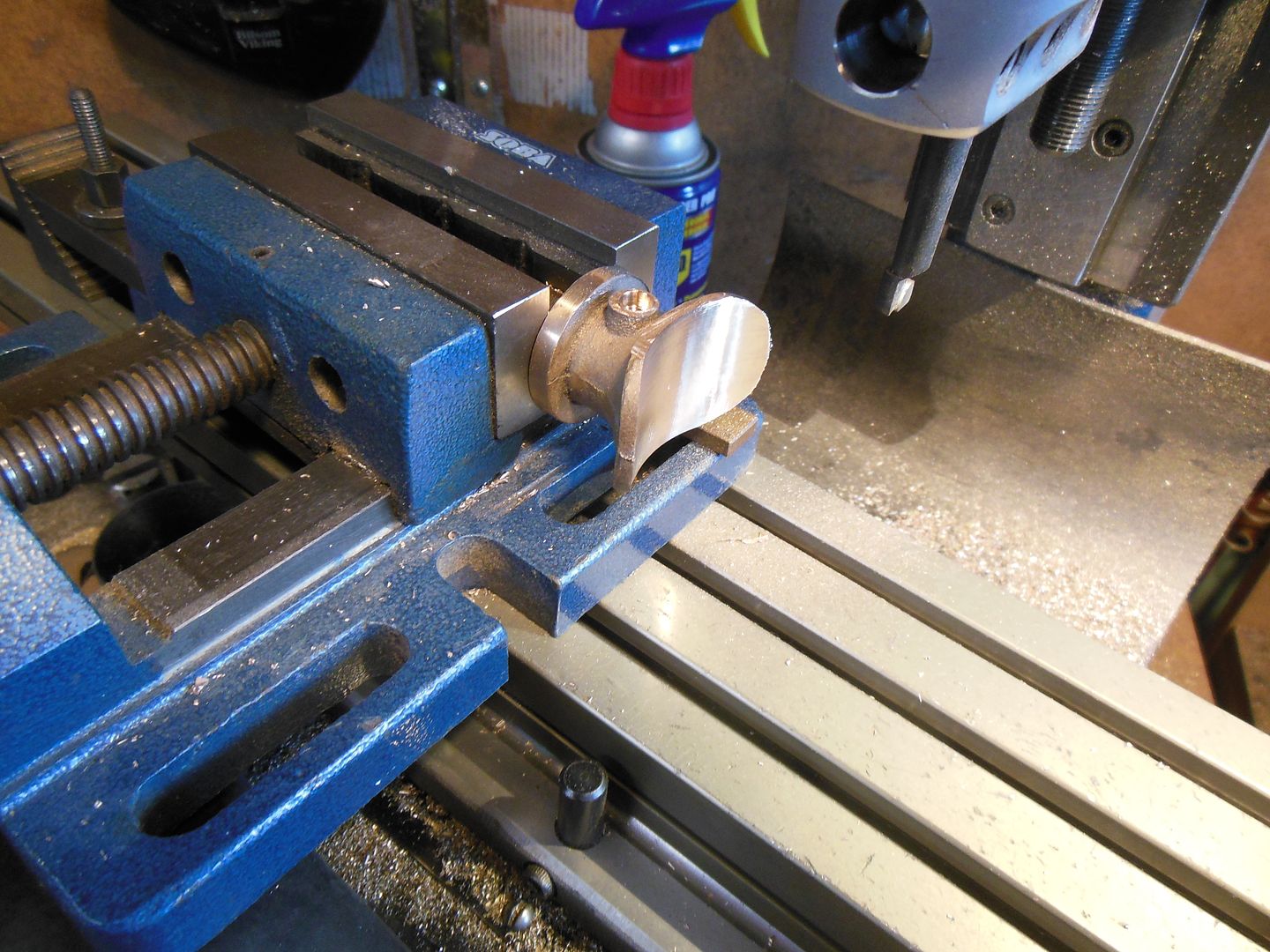

made up the various little fittings for the blower (some obnoxious bronze stock here, pain to turn, broke two drill bits, good thing

there's only 3 more inches of it left...) starting with soldering up a tee

into the mill to reduce the arms to length and drill & tap, turned the various bushes & nuts, & the nozzle,

and here it is testing for fit, after a lot of fettling of the casting

So, with this done, I can move on with attaching the smoke box to the boiler.