In between some honey-do stuff and a quick trip south to Vermont for the American Precision Museum show, have got a little further on....

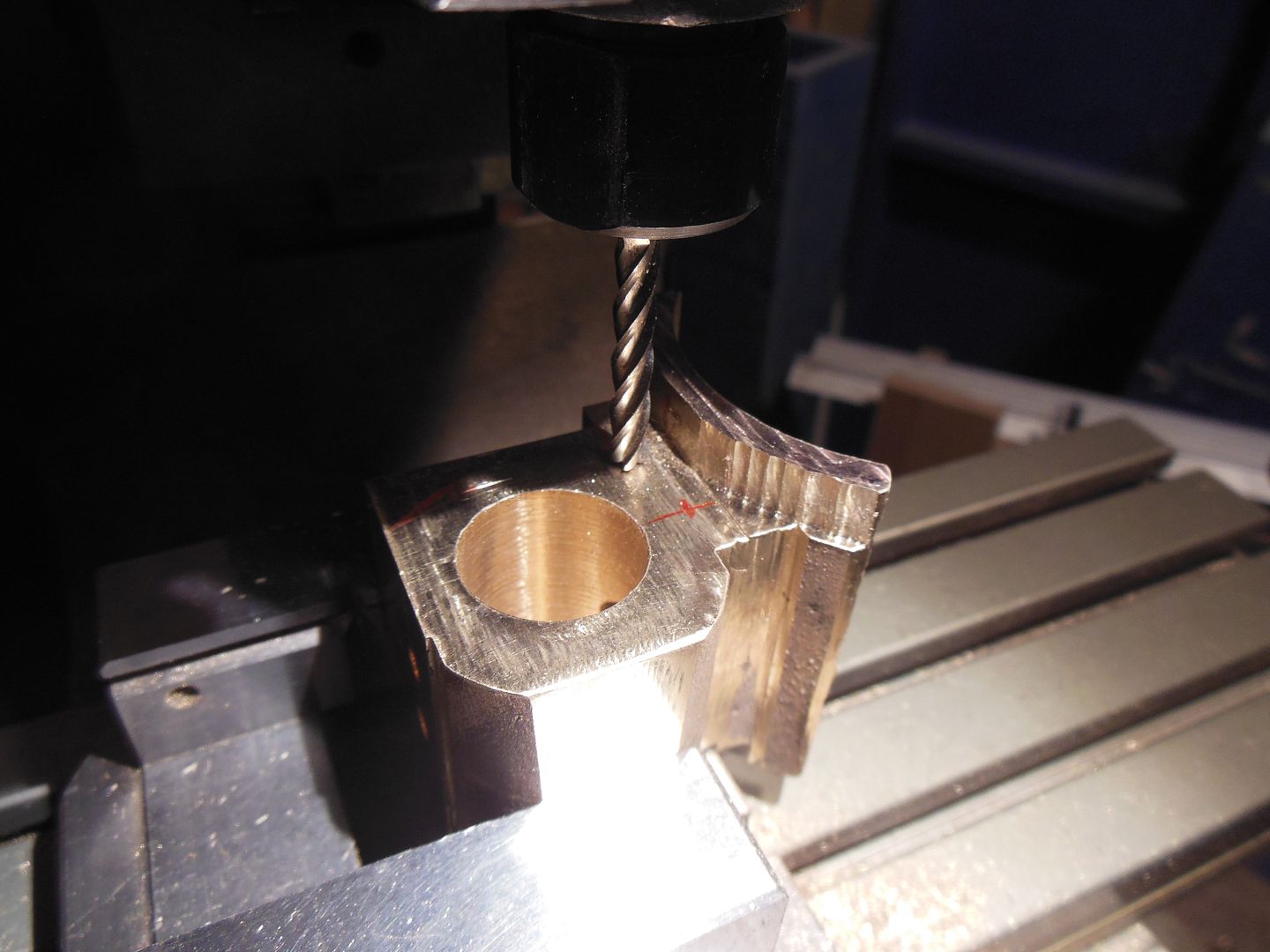

Milling the steam ports: drilled them out undersized, and them milled them out with a carbide PCB drill that happened to be the required size

the exhaust port was easier, a stock size of cutter, and then drilled a steam passage

Milled the pocket on the underside that acts as the "steam dome"

a couple more steam passages

Brought the outside of the saddle almost to size with some free-hand dial twiddling, cleaned it up afterwards with some filing, then

mounted it on a mandrel on the dividing head to bring the curved portion of the cylinder down to size

a little cleaning up, and here we are

So far so good, just have to make and install the liner for the cylinder, and then a bunch of studs for various bits that get attached....

Joe