Hi there , although you have not said exactly what type of helmet you would like to make and I know these helmets will not be the same type. I thought I would post these photos of Roman replica helmets a good friend of mine has made some years ago. Mainly as way of encouagement and to show that a man in a shed can come up with top quality goods with very little room and tools. The helmets were made in Seaton Delaval ( beside Newcastle upon Tyne, for those out the area) in a small coal house type back shed with hand tools , many of which have been hand made / adapted from bits of metal from the scrapyard, an electric drill , grinder and a normal bullfinch type propane torch. Brian who is now 78 is self taught , he learnt by books and the hard way of trial and error in the days before the internet and Youtube. Really going by the principles of 'where there is a will , there is a way' and 'necessity is the mother of invention'. So if you want to do it enough , it can be done

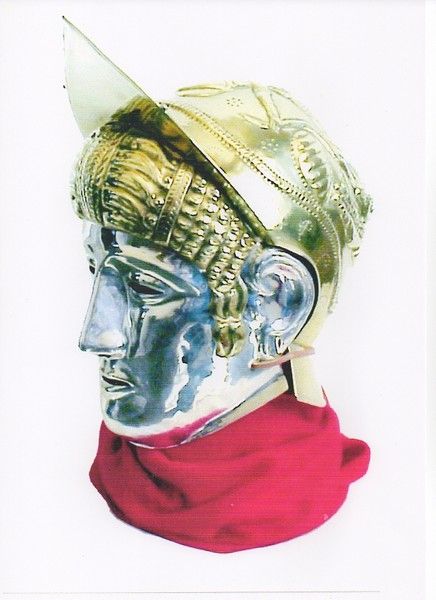

This helmet is a replica of a helmet found in Germany, its made from a spun steel bowl about 1.2mm thick, then the , Cheek pieces , neck guard , ear guards , brow peak etc are all hand cut out, formed, beaten and shaped, using just hand tools a grinder , propane torch , punches etc. All the decoration is hand formed including the rosettes some of which are silver , the rest of the edging and decoration is brass, again hand beaten out and done with punches in repousse manner ( working from both back and front of sheet ), The decorated brass patterned band above the face opening is 7 thou thick brass shim sheet, this is worked with hand tools , like a leatherworker would use, like pens with ball bearings attached to the ends, the pattern is pushed out from the rear and then background kept flat from the front. Most parts are then riveted with handmade brass and steel rivets, some coutersunk and filed flat so hidden and some proud, then the helmet is lined with leather. The cheveron pattern on the peak is brass and copper as per the original. ..................... What can you say except

If you thought that was good feast your eyes on this one

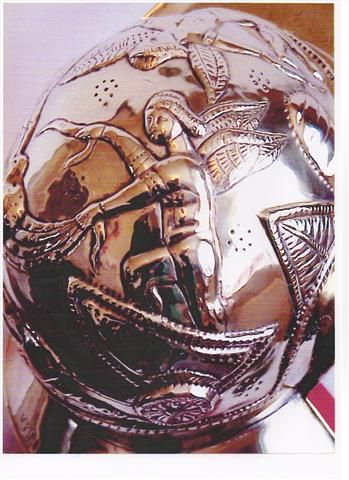

This helmet is a replica of one found in Scotland. A Roman cavalry type B parade helmet, this is all made from flat brass sheet I think, 1.6mm thick, the face mask part which includes the ears is all formed from one flat sheet , it needs to be annealed many times but is only actually hammered / punched when cold unlike steel, its annealed again once it work hardens from hammering/punching, the mask is then silver plated as was the Roman original. The face mask bit has a forehead and the embossed hair part is attached to this after the plating. The helmet is full size and can be worn , the face mask is hinged with a leather strap at the top in the centre and the leather lace secures this around the back or the helmet. I think this one is now along side the original in the museum at Newstead Scotland.

This is detail of the rear of the scull cap part , the cap is formed to shape , more by blocking than raising , that is to say its beaten into a hollow form or sandbag , once the right shape the figures are embossed in using various pundhes and hammers, again annealing when needed, the 3D type embossing is worked from both outside and inside , to work from the outside the helmet is filled with pitch and let to set to support the metal from behind, then hammered / punched from outside inwards ,the same would be done when working from the inside by filling a vessel with pitch and resting the helmet into it until it set then working that area from the inside outwards, Again what can you say except

Don't forget this is all done by a self taught man in his shed with very limited tools , space and only photos and pictures to go on, just the stubborn determined attitude that, 'it will be done', has made it happen

. I have seen both these helmets in the flesh and the photos really do not do them justice , they are scanned photos as taken before digital cameras etc.

Brian is very modest about his work and as you say matter of fact ............. 'anyone could do it really', 'if they put their mind to it' type of attitude.

Cheers Mick