Hi Scott,

I've been thinking about this a little and for what it's worth here is my opinion.....

The turner I have will hit my 5" chuck with ease... But my 3" chuck, the turret slides right up close to the edge of the chuck..You just have to check the jaw positions before start up!

I have devised and used quite a few ways of getting around the issues you describe and have rarely found I need to put a curve onto anything too close to the chuck....

But if you have this problem "We the collective" can surely figure this out!?!

So here for a start is

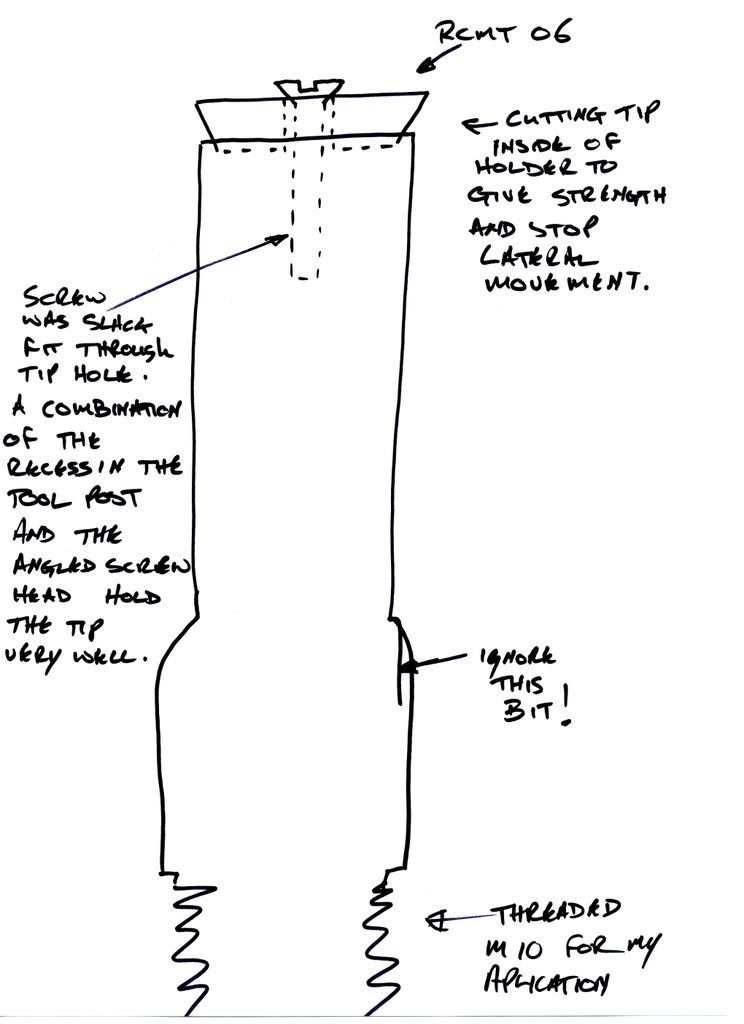

A very rough Crap O Cad for you. This is the basic idea I used to make the RCMT tip holder for my ball turner. Pictured in the thread link below.

http://madmodder.net/index.php?topic=282.0Note the tip is recessed into the top of the post, This gives lateral strength to the tip, The screw is just not enough (IMHO) to hold the cutter securely, the screw in mine is M2 but the hole through the tip is larger, about 2.4mm if memory serves. This would allow for possible movement if the tip was not recessed.

I have also been thinking about your idea for the thin plate with multiple holes. A dividing plate style 1/4 circle.

like a.... Divided head?

I haven't got multiple holes in me.... Well not evenly spaced anyway!!

(dividing head!!

..... That name has brought me nothing but trouble!!

)

Ok, Back to it....

As I see it there are a few things that would be issues and a few that should work...

Should... The holes would only have to be in a straight line from the pivot, the other holes would work but could make great swarf traps!! You could make an adjustable swarf cover for a straight line of holes. Admittedly this option would restrict your abillity to set the sizing dependent on your spacing between threaded holes? You could use 3 rows of holes next to each other with slightly different spacing creating greater adjustment? It could also be in a straight piece of flat not the 1/4 circle?

Issues... The pivot would take all the force unless the rotating base plate was recessed slightly into the plate it was fixed to the lathe by.

I assume that the forces will be putting pressure Both down and also away from the work piece, this would get worse as you moved the cutting tip further out from the pivot (please correct me if I'm wrong). recessing it into the plate would allow a lateral barrier to take a lot of the force off the pivot, but it would also make a great swarf trap, That probably would cause issues? With the round turret it stops swarf getting into the base.

That said it could work really well?!? I've never tried it... This is just all from my head! I'm not trying to knock you down, just trying to add my ideas! (just be aware of the forces on the cutter!

)

Personally I'd just have a go at it....

I've made all sorts of tools that were damn useless!!!

I still enjoyed the builds, I like the challenge of making a thing I have thought of almost as much as I like seeing it work.... Almost

Sure it's frustrating if 4/5 hours work is not of any use.... But I sure learned a lot on the way (read through my Aoelipile thread.... You'll see the waste of time, [the cutter!

] not all of it but some! Some of it was salvaged to make another tool

)

Well after all this writing I suppose I'd best see what I get in response ehh??

I'm hopefull that some others will add their opinions?

Ralph.