Ok, a bit more thought and here's the order that I'd attempt it if I were doing it myself....

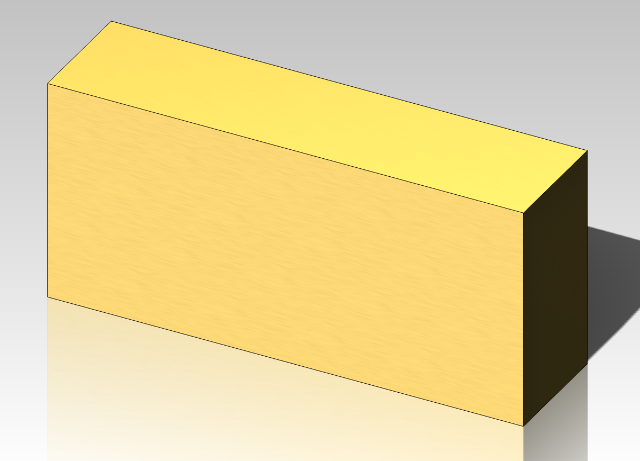

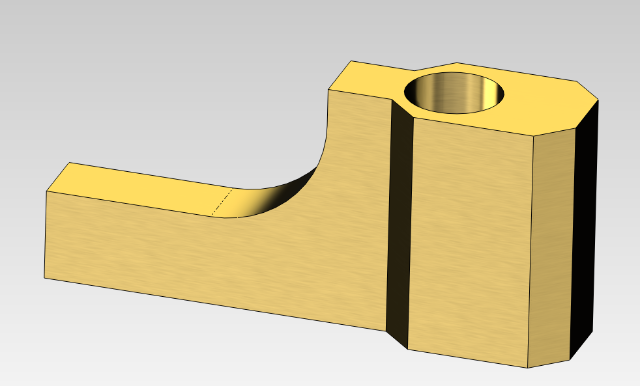

Machine your block to overall dimensions:

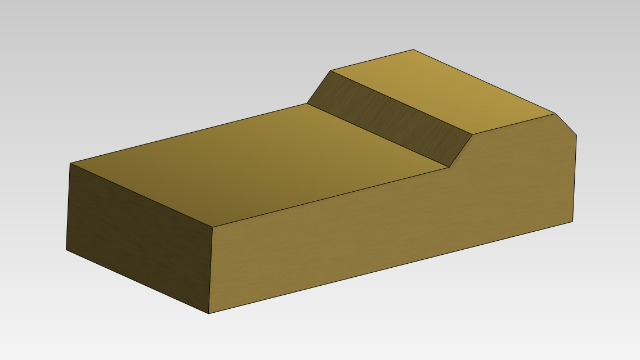

Clamp laying down in vice on parallels, use end mill and chamfer mill:

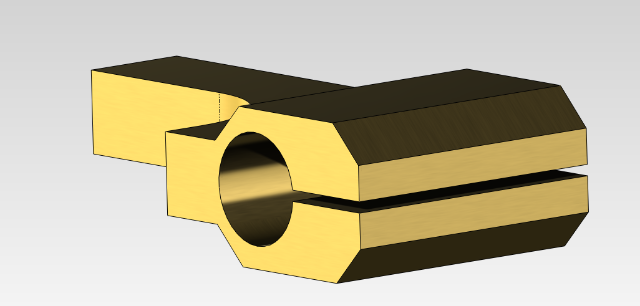

Flip and do the same on the other side. Drill your freakishly small holes while it's laying down this way. Tap them before you get too far along as well:

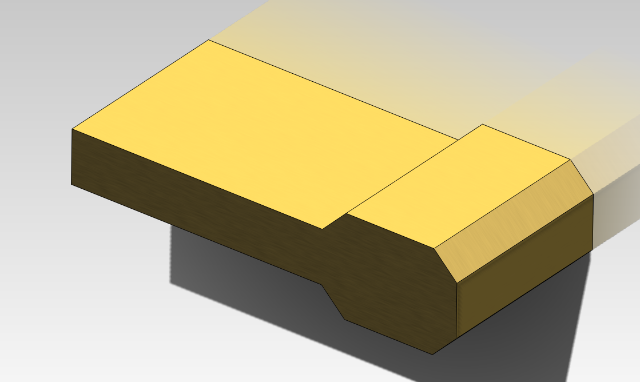

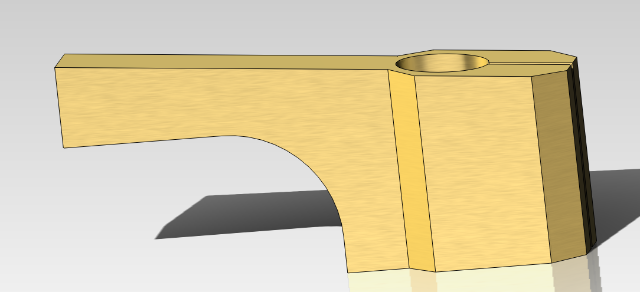

Stand part up in vice, gripping on thinner section and cut radius with 3/4" ballnose (or whatever is at hand, as many wouldn't have one of these)

Same setup, drill/ream the vertical hole:

Lay flat again, use slitting saw to cut the slit:

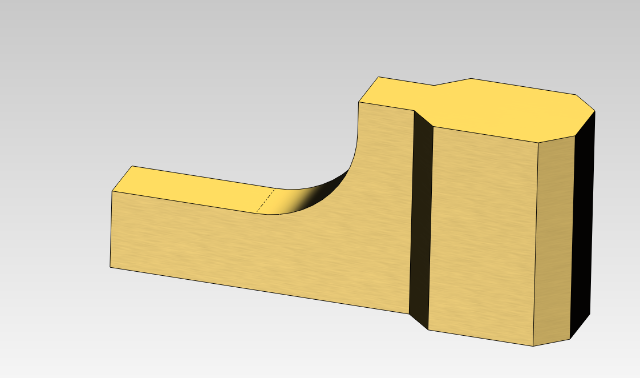

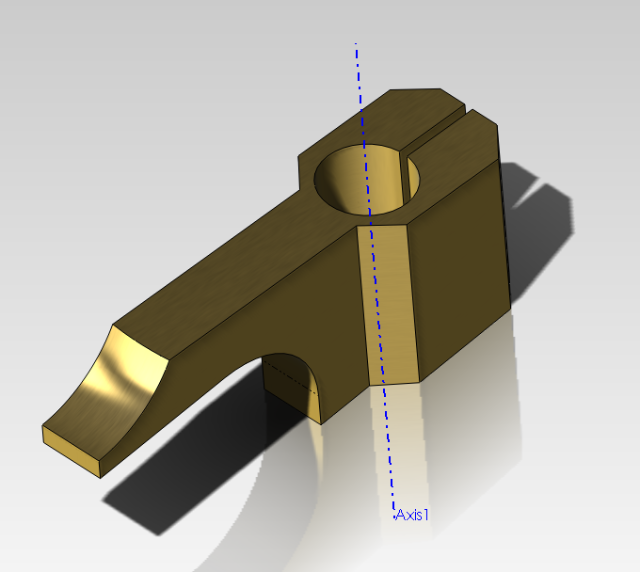

Place on angle block or whatever you come up with to set the part at the same angle as the top should be milled. Again, clamp on the thin section and hang the "body" out the side of the vice. Depending how floppy it is and how heavy you want to cut, you may have better success clamping on the main body using a 3/8" rod in the vertical hole so it doesn't compress:

Clamp to a 3/8" rod, chuck in a lathe and use a ground form tool with the correct radius. Or use CNC to profile the radius:

How did I do?

With a bit more thought, the number of setups might be less but this seems a pretty step-by-step foolproof way.

-Sparky