O.K Here we go.

It seemed to work so now I'll bore you with it.

first I grabbed a lump of steel rod and turned a No2 morse taper.

I also turned a parallel portion to be a sliding fit in the centre hole of the chuck.

I drilled and tapped the small end of the taper m8 for a drawbolt.

after parting off and reversing in the lathe I tidied the end up then drilled and tapped m8.

now I need two washers, one for the lower end and a stepped one for the chuck end.

now to assemble,

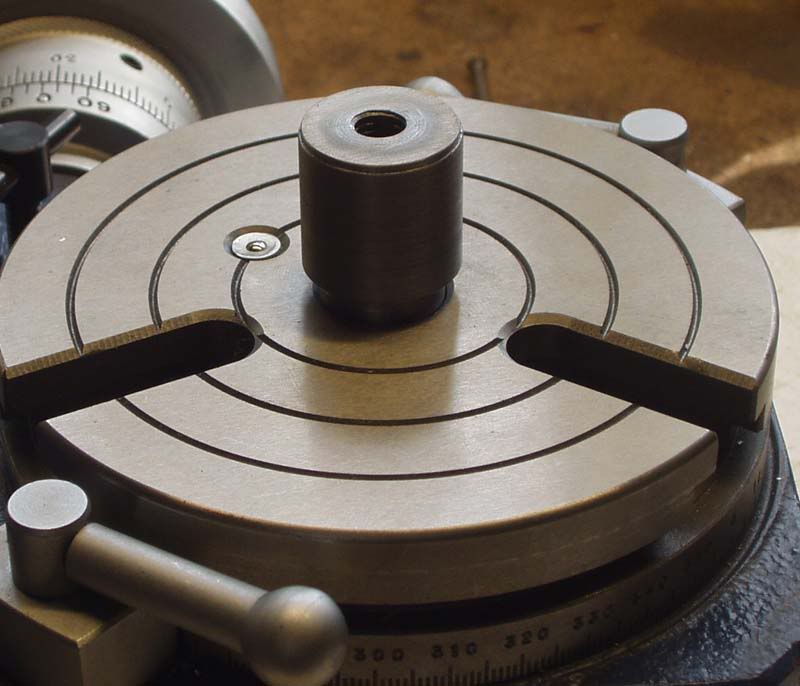

fit taper in table.

the length is just right.

then the drawbolt,

turn upright and slide the chuck on and retain with stepped washer.

and done.

this method does restrict the smallest size piece I can hold in the chuck, its about 22mm but I have a collet chuck on a backplate that will fit with no bother and that will take up to 20mm.

If I have something thats 21mm then tough.

thats all folks.

Roy