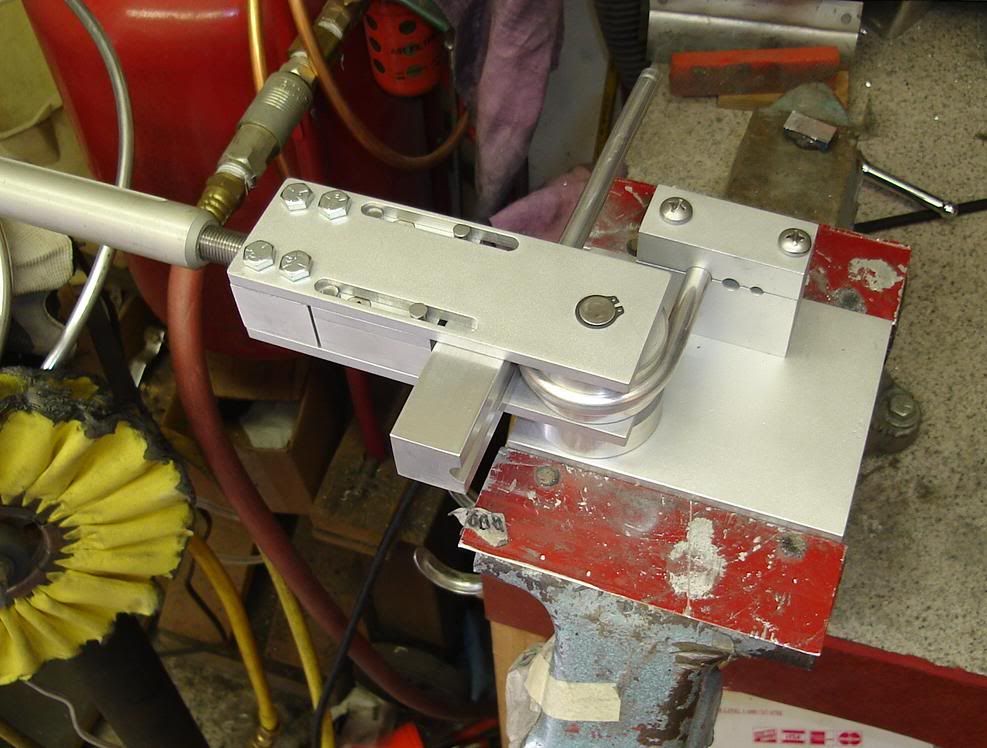

I've never used one of these nor seen one except in pictures. I decided to build one using ideas from others, but throwing my own ideas in as well. I built 3 rollers and 3 'follow blocks' for 3/16", 1/4" and 3/8" tubing. They are 1" high so that in the future I might be able to bend 1/2" and 3/4" tubing. Here is a pic of it without the follow block in place. You can see the roller bearing that is encased in a block that has 8 pins for guiding it in fore and aft movement, depending on the diameter of the roller. The threaded handle pushes on the block and hence the bearing.

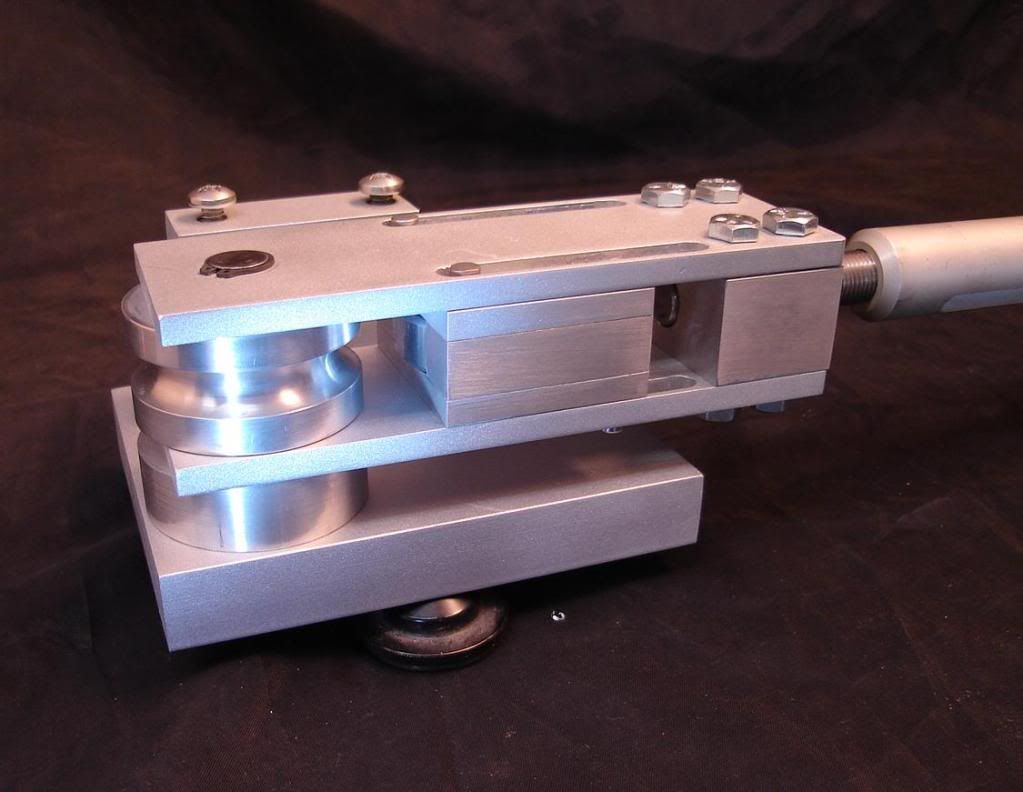

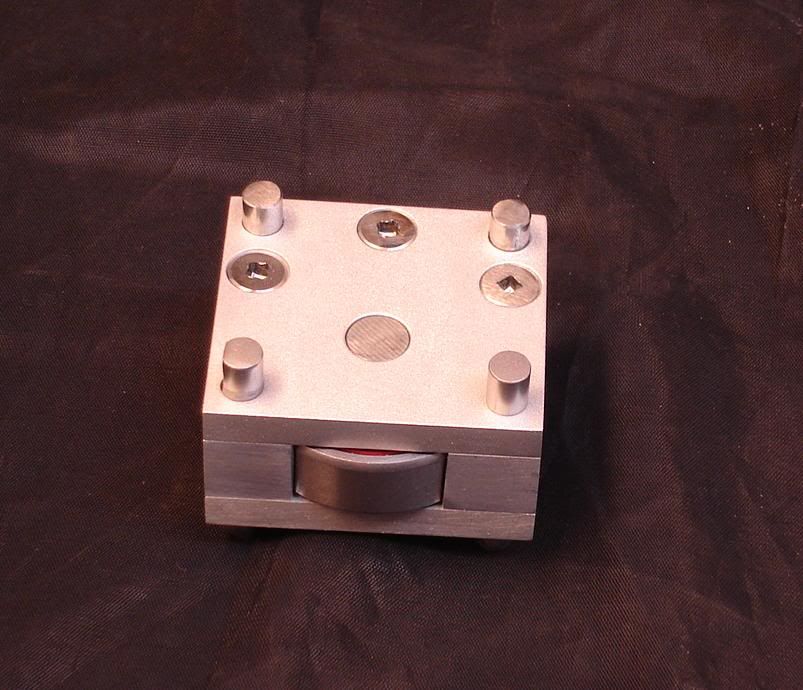

A couple of pics of the block and bearing:

Here are all the pieces:

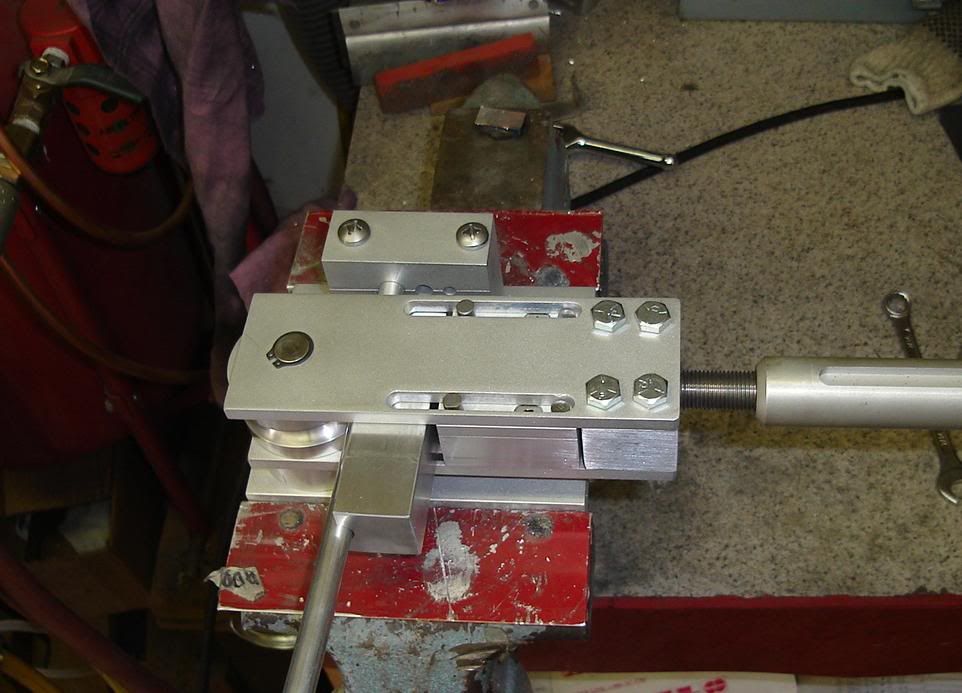

All set up and ready to bend:

As you can see below, at 90˚ I have run out of follow block. The only insight I had into the length I should make it was from DiAcro, which said the length of the follow block should be 3 1/2 times the radius of the roller for a 180˚ bend. Perhaps my math is wrong. Anyways, I just backed off on the handle and reset the block.

And finished: