...if i want to keep the cost down then i have to do what i need to do...

I definitely understand

...The link i showed before for the D1-4 chuck clearly shows bolts on the front next to the bore. What are they for if nothing to do with the cam lock pins?...

They are nothing to do with camlock pins. Normally chuck is made in two pieces and these bolts are there to hold the two halves together. On chucks where you don't see them at the front, they are simply done from behind:

For example, bolts in the front:

Bolts (9) are holding together front (1) and rear (2) of the chuck.

This is an example directly mounted short taper spindle chuck. Bolts (8) could be replaced by camlock pins.

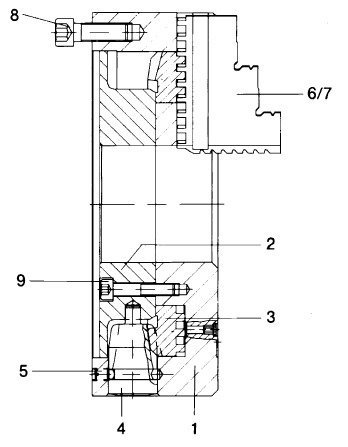

Or another example, bolts from behind:

Again, bolts (9) are holding together front (1) and rear (2) of the chuck.

This an example of plain back chuck, requiring backplate to fit it to the spindle.

Backplate, in this example, is fitted from the back using bolts (8).

Often/sometimes these bolts (8) are fitted from the front.

You will see from this (I hope) that PCD of the bolt heads you see on the front of the chuck in picture you have linked has nothing to do with your needs and is entirely at the discretion of the chuck designer. You might be lucky, but than you might not, plus you can't remove them anyway, or your chuck will fall to pieces

(unless you introduce another way of holding the two halves together?)

...this is a high precision lathe which i bought and put back together on a shoe string budget...

Yes this is very nice lathe indeed, I am envious

...I've been waiting over five weeks to make some proper swarf with it and it just gets a bit frustrating....

I understand your frustration, but if I were you I would get on with using four jaw chuck, which I understand you have?

I pulled the back plate off the original three jaw tonight to see if i could do anything with it and who ever fitted it originally did a bad job. The holes were drilled through from the front of the chuck and they do not line up at the back with the nose properly. All for the bin..............

Why should it be for the bin? Holes in the backplate are just clearance, just open them up. Location is provided by the spindle taper, bolts are just used to secure it on the spindle not to locate it.

I am not sure I understand you here?

Chris