My "shop"' now officially has machine tools. My Taig lathe just arrived today so I wired it up and got turning.

Basic wiring, three prong ends cost too much so I used a simple extension cord.

All the parts. the first thing that struck me was the size. While shopping for a lathe, I had a hard time determining size from the photos, and measurements. I included a US quarter for those shopping to maybe get a little better idea of how small it really is. While I was thinking something a little bigger, as you can see from my desktop I really don't have space to spare anyway.

I'm not a big fan of the motor mount setup. It uses the weight of the motor to tension the belt, and the bolts thread into the particle board, I couldn't start them by hand so I used my drill, again my give a little scale to those looking(and for those more curious among you I can get better scale pics by request).

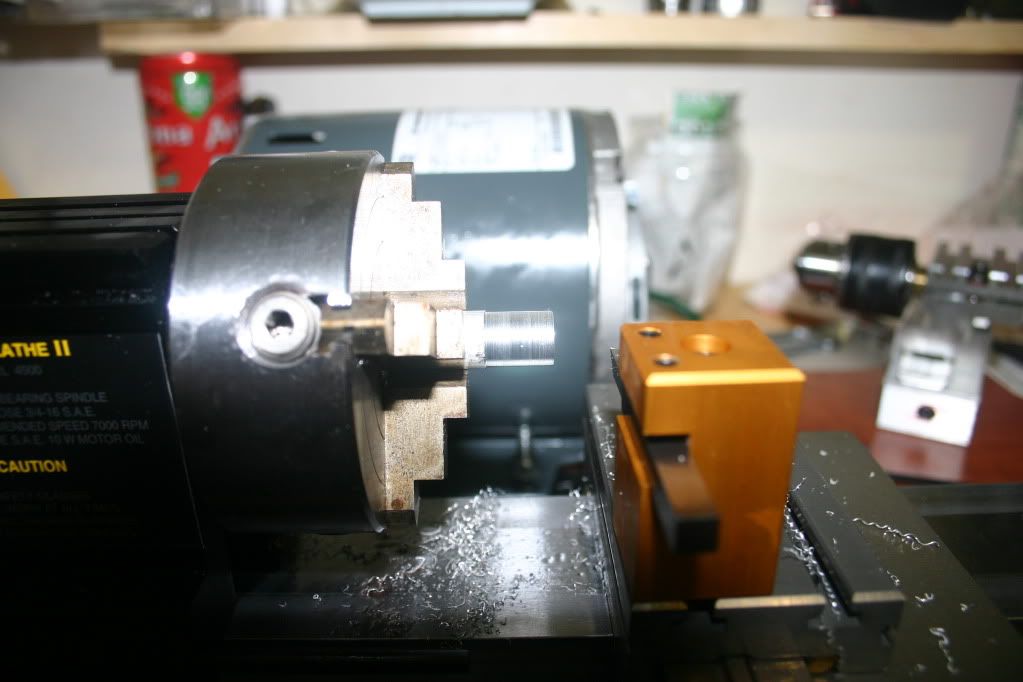

All put together and turning a test piece. Getting the four jaw chuck centered was a real pain. I think a three jaw is in order for stuff that doesn't need the accuracy/versatility of the 4 jaw. Also need to figure out a setup for the dial indicator that doesn't take an hour to finally get it setup so I can get a reading.

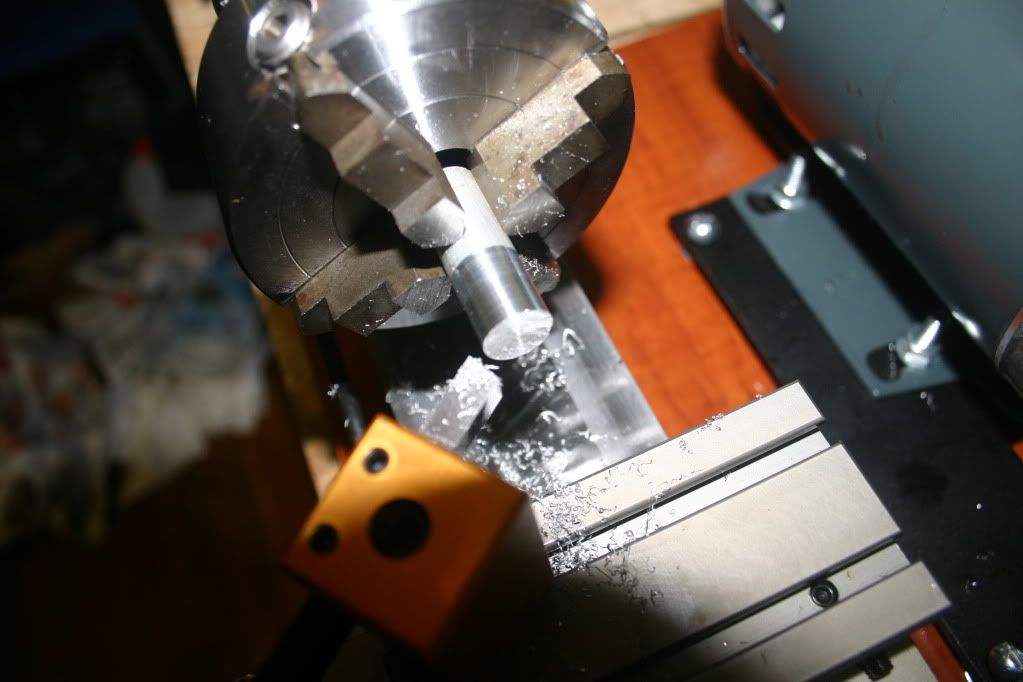

Just playing with different speeds feeds and tools

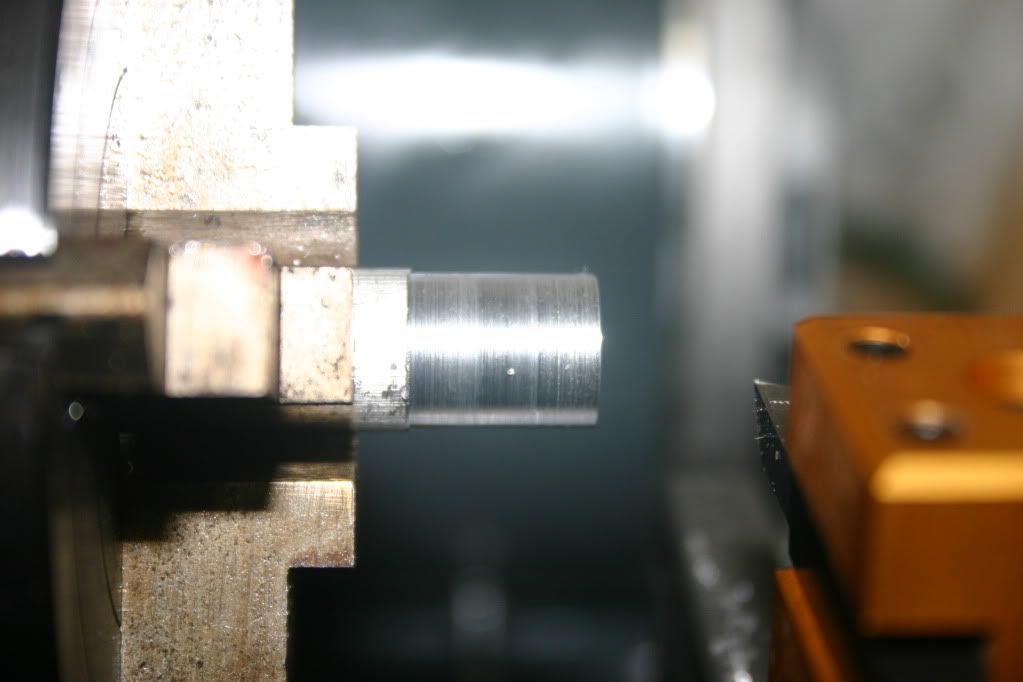

After I finished playing, I decided to make something, a replacement tip for my protractor to use it as a divider.

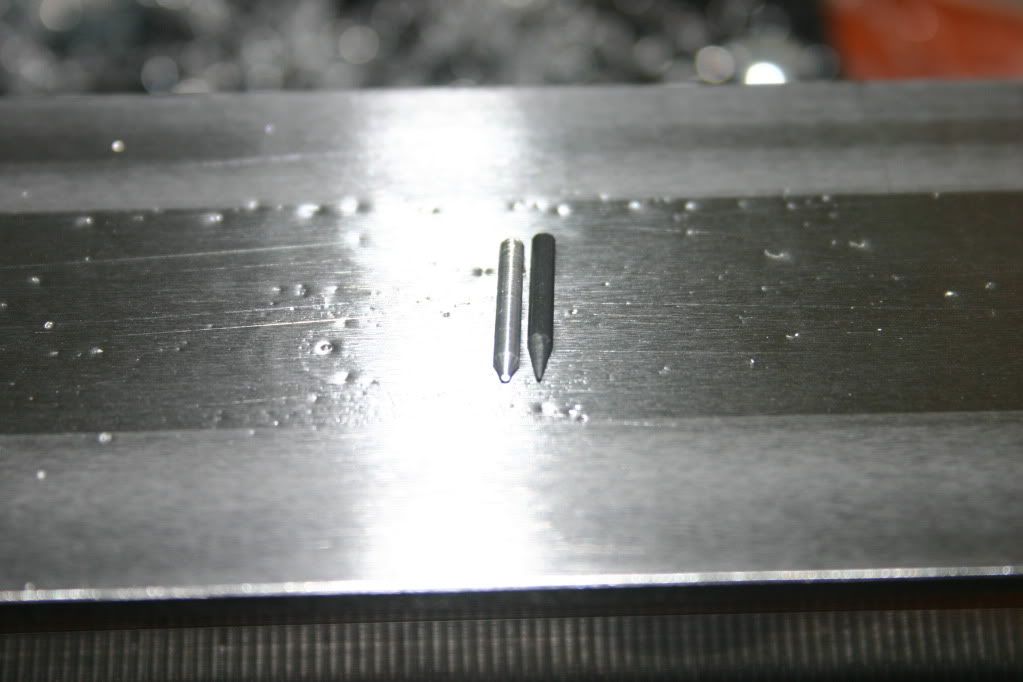

Cut off the stock and next to the graphite

Finished product, not the best execution, but I'm quite happy with it based on the tools I had when trying to cut the taper, and for a first project its nice to have it done on the first day.

It seems that I still need to lap the bed again, the cross slide still has a little play in it. I can push on the tool post and it will make a slot about .001" deep. When tightening the gibs it just locks up and loosening enough to slide free I get play.

And finally all cleaned up and ready for another day