After nearly thirty year I have taking up an old hobby that I really love, working with a mill and a lathe, making steam engine and things around it.

It is such a feeling, after many hour and late nights, the project I was working on, finally been successful.

Some weeks ago Iíve got a packet from Tiny Power, US. It was a casting kit of a steam engine called ďLittle Kathyď. She was presented in a nice box, with plans and a reprint of an orginally article from 1926 published in The Modelmaker magazine.

There was something about Little Kathy makes me looke a little closer to her. The velve cheest is diffrent then Stuart 10 for exampel. The appearance makes her to look like the real thing Ė a Steam Engine.

One thing, to try to make something from US is that they always talk about inch, I on the other hand, is born and raise with millimeter. Converting from inch to mm is not allways so easy so what I am going to do is as long as I can I will stick with the inch, but for me when I building I always convert to mm.

They have also the enoyng thing that sometime they describe a measure as 1/4 and sometimes 0.250. And also when talking about drilling they have #53 and so on.

My solution was to create a computerprogram where I could translate all of those strange numbers to mitric.

There was two plans, the orginal plan fron 1921 and a uppdate plan.

Starting with the base..

..some milling..

Then drilling and threading the bearings to the base.

Finish the column

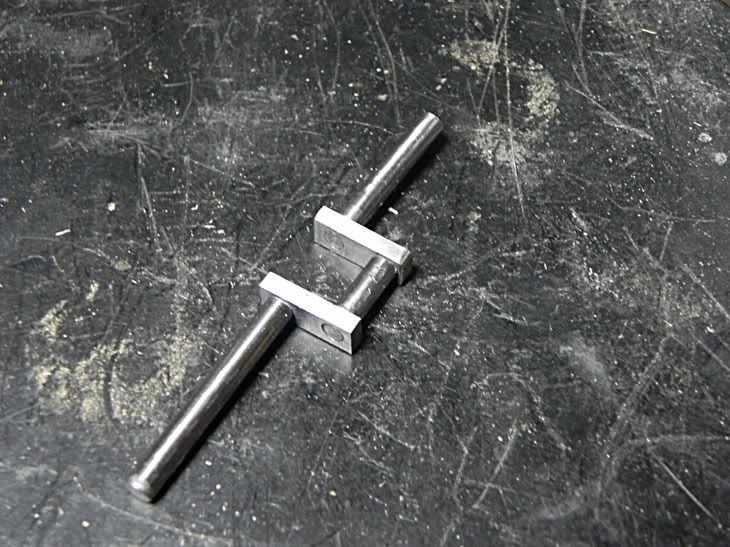

Making the crankshaft..

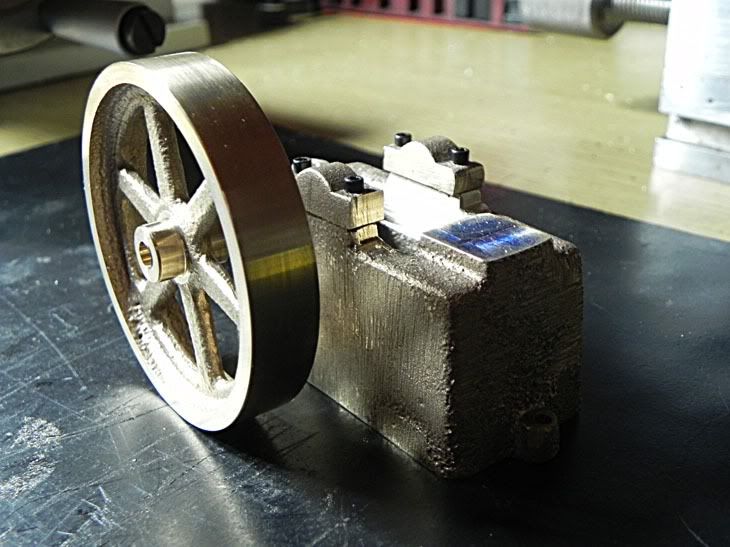

all the part together..

.. and finish

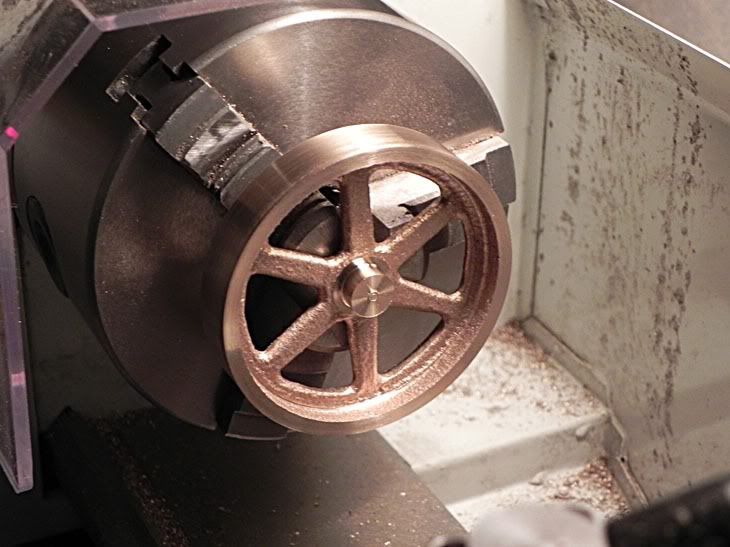

Then the flywheels

And so far..

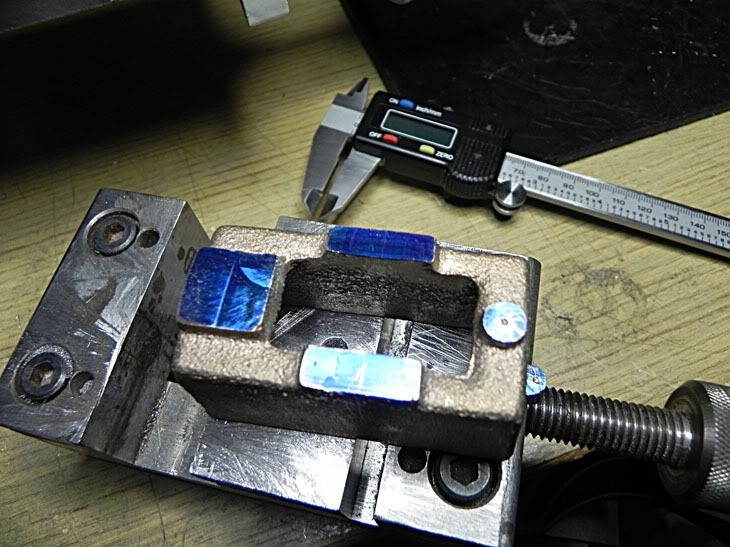

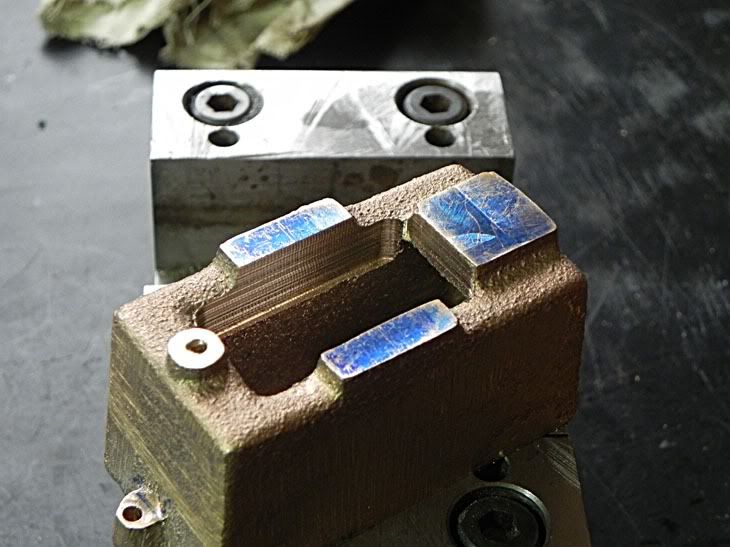

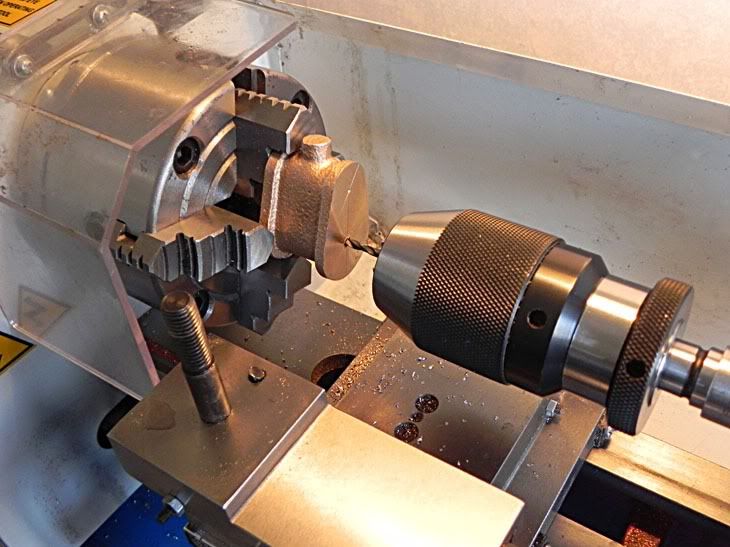

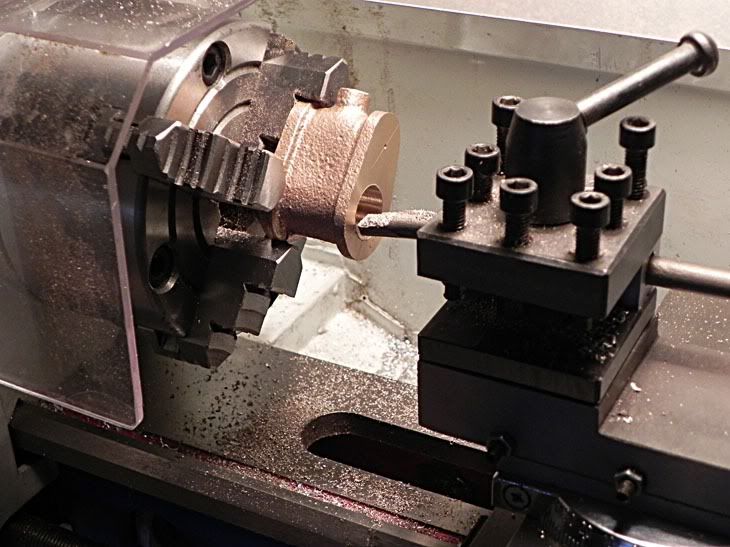

Somthing is comming together. Now while I am waiting for some equipment, Iíll go on with the cylinder. First some center hole in the lathe..

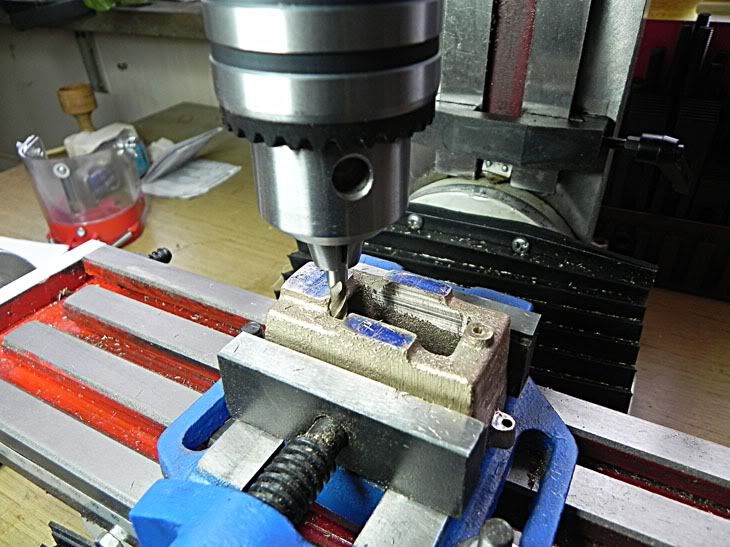

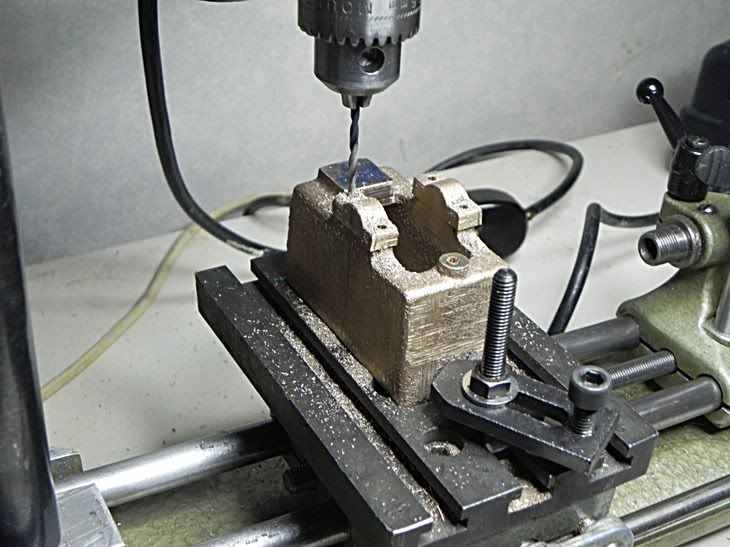

next I have to drill ..

then some turn in the lathe.

I will be back when I have done some more progress, until then

Hej dŚ.

Benni