Since this is a new thing they have not long been out and man would not have heard or seen them.

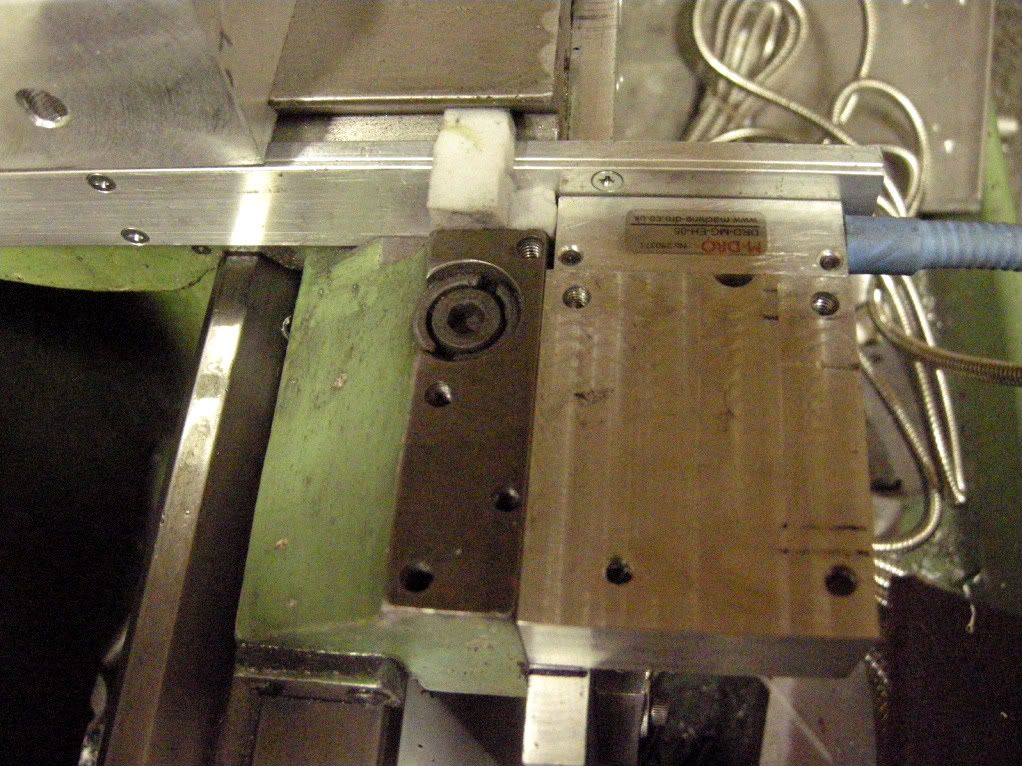

http://www.machine-dro.co.uk/index.php?target=categories&category_id=60Heres a piccy installed on cross slide.

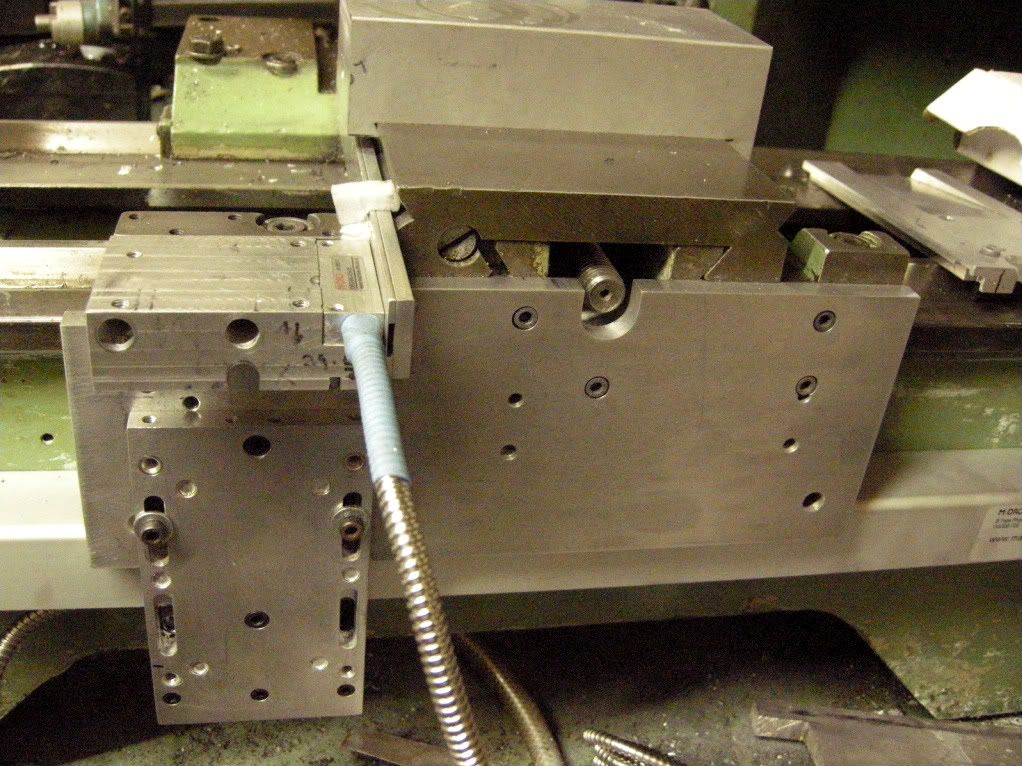

When tail stock butts up to two part cover i have only lost 2mm. Even the micro glass scales its a damn site larger than that and could be the prayer to most. These need to be positioned accurately within 2 degrees runout and within 0.54mm away from two part cover or they wont read!

I do have a cover that goes over the top. Thats 0.1mm between encoder and two part cover perfectly centred no shims, total runout 1/2 thou on cover, they arent that accurate an extrusion, more than good enough.

I did slap machine in a recess in carriage to lower the cover 5mm, i still needed the 90 degree dovetail in cross slide.

Thats a regular 720mm long glass scale for X axis with both cross slide i needed to beef up the protection as swarf build up will continuously be pushing on them. I dont want to keep stopping every few minutes and grabbing arm fulls at a time for sveral hours on end. More production orientated.

I need to still make something to protect over hanging two part cover but will be doubling this up with a capstan style depth stops- if i can.