Well it's been a long (ish ) day and there has been a great result.... Hopefully it will stand the next test?

I spent most of the day with John in his grotto making a form tool and the die for my hemispere making punch thingy me bob....

It went a little like this....

We started with a little instruction into what we would like to achive, John had been planning whilst enjoying his coffee

it was not to hard to get to grips with, just make a tool to make this happen!!

The tool blank that I had produced earlier in the month was to be re-designed and put to use as a form tool to be used in the lathe.

So here are the pic's and a little description of what was going on....

The tool was held in an arbour and the rear was cut amay to avoid it hindering the tool when inserted into the workpiece.

It was then hardened (I have a little video on this which I will sort out and post ASAP)

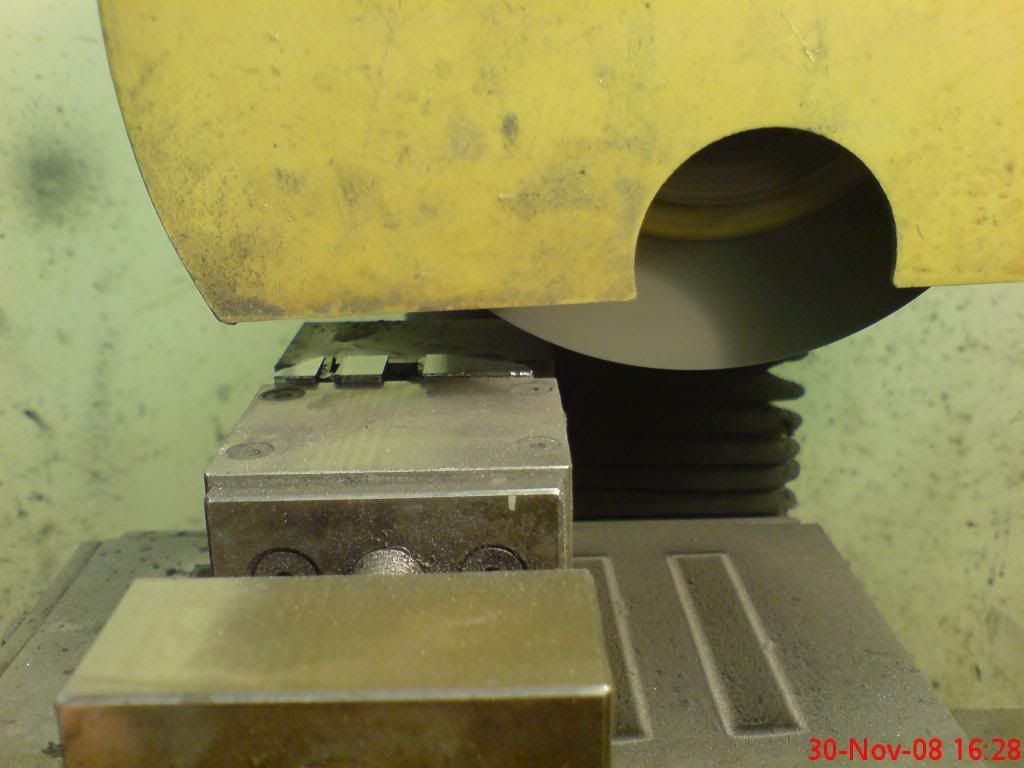

Then the tool was re-fitted to the arbour and a tool post grinder was used to grind a 20' relief angle to the rear of the cutting edge

that was then given a little polishing.

A chip breaker was then ground into the front face of the blank and it was cut through slightly off centre (pound coin for size ref') the right hand piece is to be used as the tool.

Then I got to use the surface grinder.... Interesting process of getting a really smooth highly accurate finish in hardened metals. (Some video of this too... I will get them posted soon.)

The tool was then cut again this time the back edge was removed.... A crap 0 cad will be added here ASAP as I forgot to get pic's with the excitement! Sorry.

Now to the die....

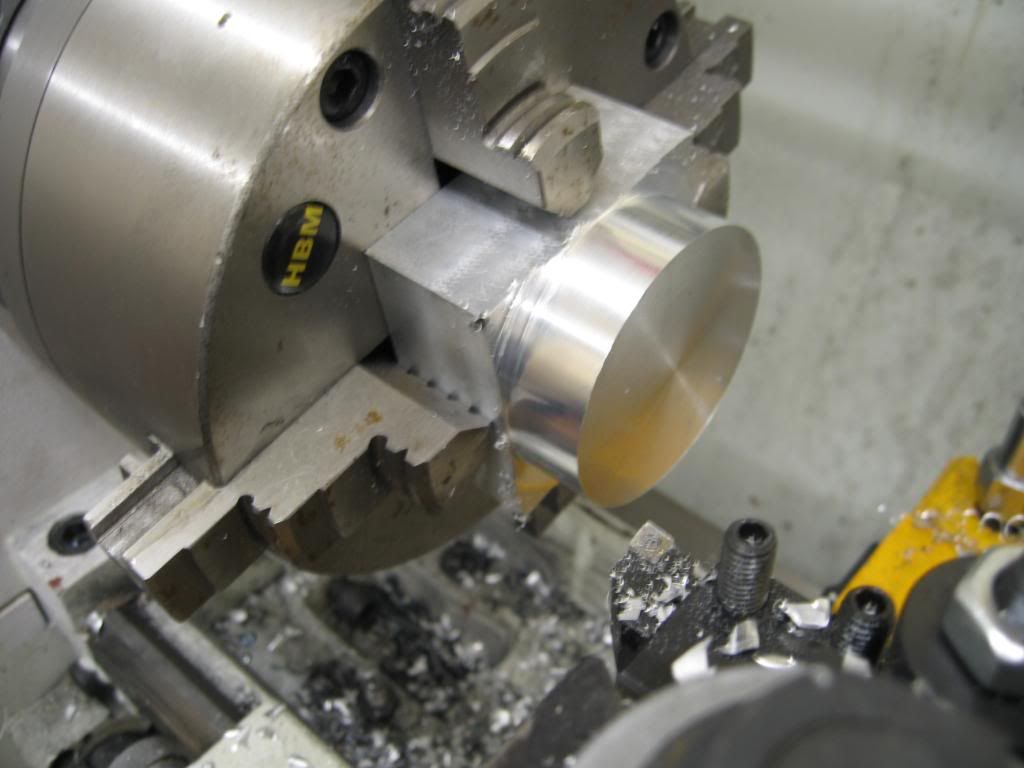

A 65x65x50mm Aluminium block was held in the self centring 4 jaw and the front 20mm was rounded off...

This allows easy form tool alignment later and also provides means of clamping the die to the press bed.

A 5mm hole was drilled through the centre and then the centre was opened out to 25mm with a couple of blacksmiths drills.

Then the fun starts.... The first step, increnmental cuts were taken, to rough out the shape of the dome required.

Then the form tool (held in a QCTP holder) was used to create the final shape.

Another video.... Yes I will sort them out ... It's just too late now!!

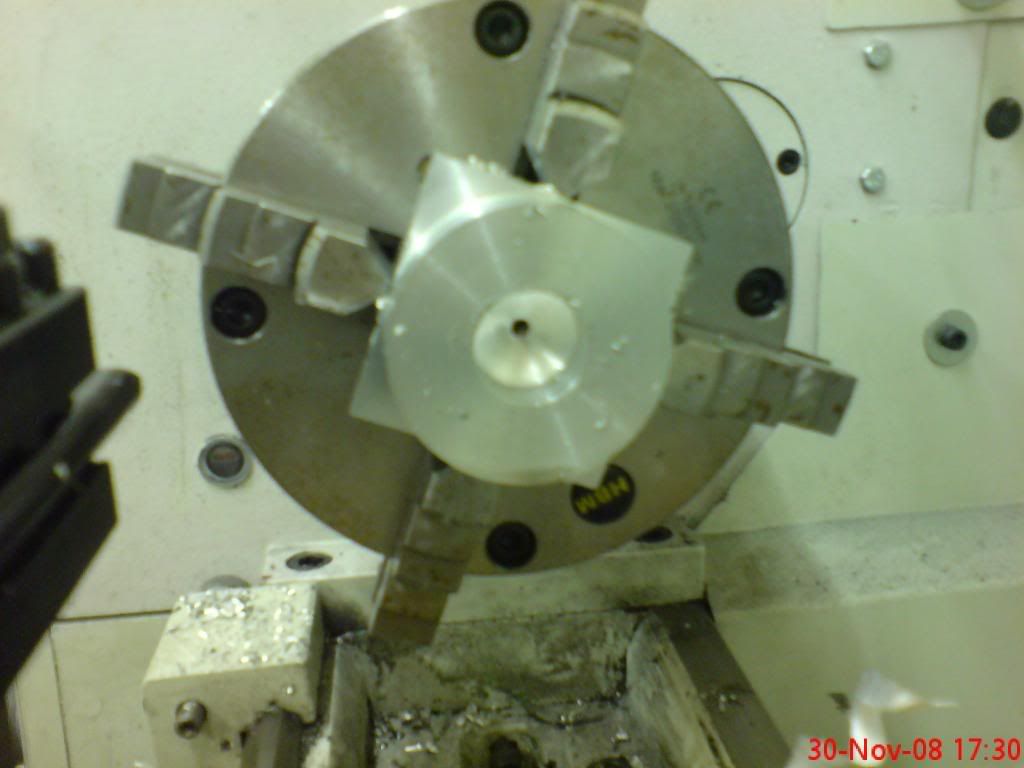

The final result....

and punch head in position....

We did try a steel version just after this, but as the steel came from a garage door weight and had an unbeliveably hard part in it, it ate a huge chunk out half way down the form tool!!!!! It was working quite well untill super hard bit reared it's head!

So if this doesn;t work for whatever reason.... It's purchase time of some better free cutting mild steel and make another form tool!

Well that's it for this evening, I've learnt all sorts of interesting stuff tonight, and used a few machines that I have never had the chance to before.... I know you hate this bit John but Thank you all the same

I'd have not got anywhere near this far without your help and entusiasm

I will sort the vid's out and get them posted ASAP.

I'll also get a few bits made up this week hopefully and then put all this work to the test.

Good night!

Ralph.