Well I finally got it to run!

Today I did some more fiddling with the eccentric timing, bump cams positioning, and the piston rod length on the cross head and what do you know it started running.

I guess I wasn't so crazy after all and with all the encouragement to not give up on this from the members of Mad Modder I accomplished what I hoped.

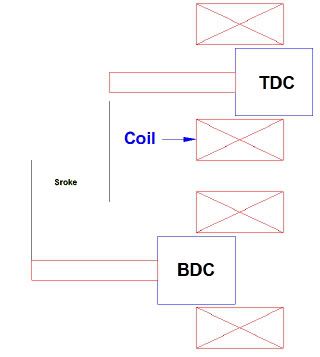

You can have a double acting solenoid if you position the armature correctly when the electrical pule is applied. Since the solenoid works by drawing a iron armature in to the center of the coils magnetic field, if you do that at the same position at each end if the coil and time your switch correctly the coil should pull in on the armature from each end on the coil.

This switching has to be done just after TDC and BDC as several posters mentioned. Part of my problem was I was timed to actuate the switches a both ends of the stroke just prior to those points. You can get away with that on a IC engine because you're compressing a gas but not on a solenoid!

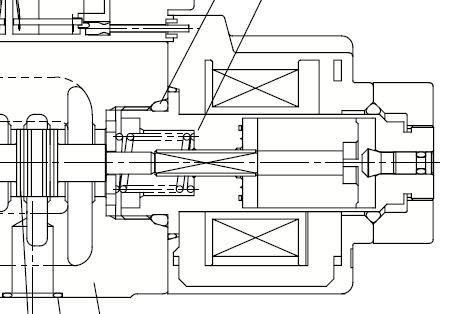

Another thing that was causing me grief was the solenoid I chose to use has a very narrow coil width since a hydraulic vale spool only needs to travel about .250 to .375 inch so it only needs to pull the armature that distance and it is spring offset the other direction. Here is cross section off the solenoid I used.

I believe this made the setting of the timing more critical since my total stroke is 1.500 inches. Also, a rotatory cam would probably be better than my bum cams since you could better control the on time of the coil for more power.

Anyway, thanks for all the replies, suggestions, and encouragement.

I probably would have given up on it. It's still not completely finished. I want make wood base, mount a on/off switch, and fix the wobble in the flywheel among other things.

Also, I don't need the governor - it doesn't run that fast.

The coil heats up quite fast so running time may only be about 3 - 4 minutes.

Here is a video of actually running: