Time to put a bullet the head of this thread/project and put it out of it's misery. Lot of things have happened since I posted last. Most of them discouraging. Here are the finial steps of putting this experimental engine/motor and the frustrating end.

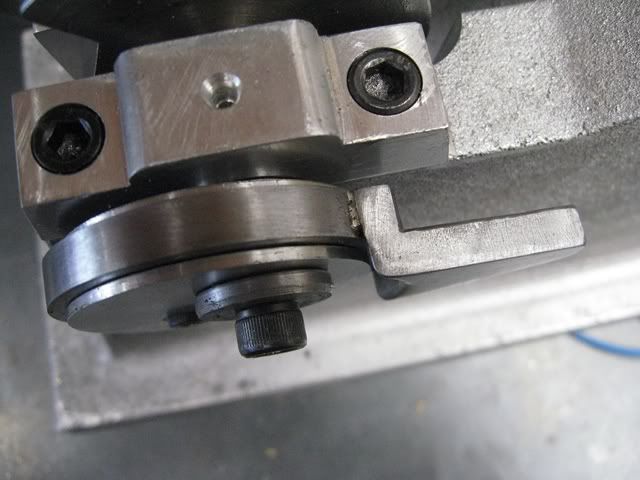

Making the eccentric:

Soldered together showing the offset:

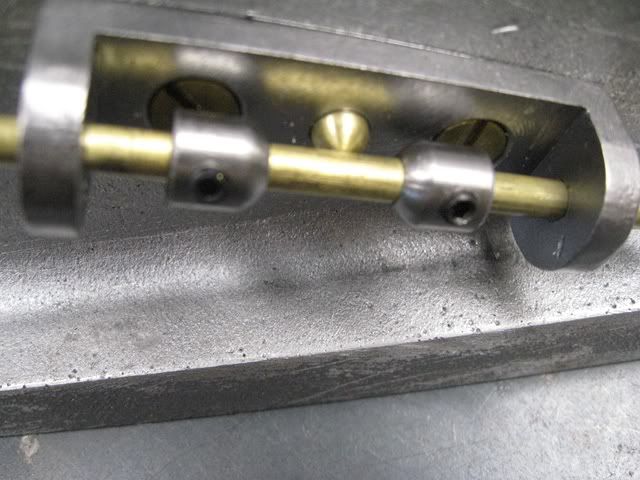

Switch rod guide bracket and actuating cams:

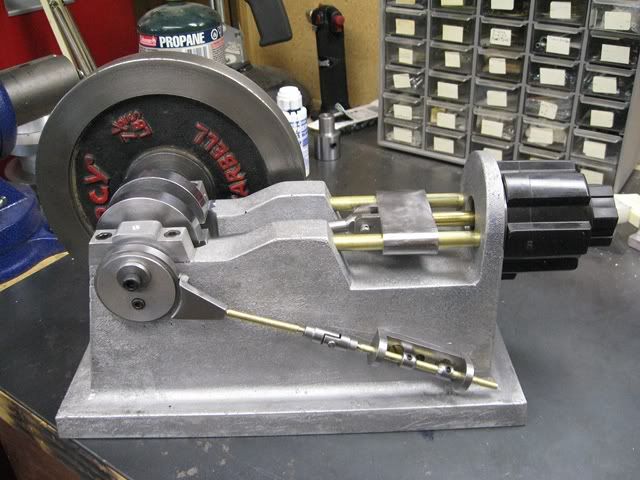

Mounted on the frame:

Switch actuator rod and how it is actuated by the cams:

Switch bracket and it's mounting in the base. The switch was out of an industrial limit switch and has a spring loaded plunger:

The overall arrangement of the switching setup:

Looks like it might work, but here is the result:

I have spent a lot of time trying to get this running, but no combination of eccentric and cam timing can make it continue to run. I believe there is just too much friction on the crank bushings and connecting rod to allow the momentum of the fly wheel to continue the rotation. Also. the impulse from the coil is not strong enough and it starts heating up more than I would like (I expected this might happen, but not as quickly as it does).

I have reached that point where I must give up on this configuration, redo the bearings, or convert the bones into a pneumatic engine, which what is most likely to happen.

Oh well, not everything turns out like you would hope of expect it might. I learned something form this exercise that will be useful on the next project. Time to put this one on the shelf for a while and comptenplate the adventure in self taught home shop machining!

I want to thank all that all that followed along on this episode and I certainly enjoyed your comments and encouragement.

Sorry the end turned out kind of anticlimactic!