Hi Mr Star

Just taken a look at this...

http://www.warco.co.uk/Major-Milling-Drilling-Machine-E1466C1C6A.aspx#Assuming that is the one your talking about then it's a very close cousin of the "new" second hand machine I just got my grubby mits on.

(Also similar to a Chester eagle.)

Just a few words.... If your going to skim cylinder heads then you will definitely need a power feed of some form. This is a must IMO, I'm not talking out of my...

I'm a time served mecahacanic and former engine re-manufacturer and can tell you that it's going to be very hard going to get the finish required for a good seal without a power fed machine.

9x7".... Quite a large cutter required I'd have thought

I'll have to look at my machine, see what it'll cut and still allow the cutter to clear the work, cause that's quite important if you want a uniform skim. Should be fine... But I'd like to check before I say so. I suppose if it's trammed correctly (Adjusted to cut true) it should easily work.... I'll still check though.

Some video's of a guy I'm subscribed to making a flycutter with more mass and then one of his few on skimming (I know it's on a bridgeport, but it's the set-up and cutter I'm showing, it only uses one tip, this is standard practice with skimming

)

&feature=related

&feature=fvw

Check out some of his other videos too. A larger (greater mass) cutter is made and certainly helps with the finish.

Have you looked at the second hand market? My machine came with a power feed and was under half the cost of the warco in the link above. I can tell you it works perfectly well, see the post on my shop...

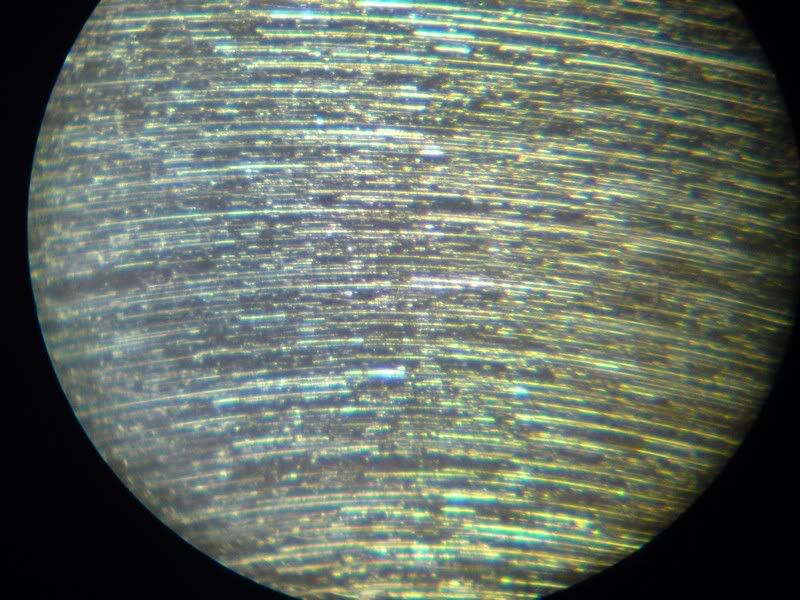

http://madmodder.net/index.php?topic=395.15 This shows my new mill and the finish it got.... Once I learn to grind the flycutter tools correctly the finish will be far better. I had a go at that the other night, got this funish from one out of 4 tools I ground up..... It's not as easy as you might think!! (got my new boring/facing head to use yet too

)

And for those who like detail...

The round column thing..... Well, My last two mills have had them, I know other very well accomplished gents who have owned them and created awesome engines and fettled fantasticly odd stuff with them.... I think they work fine.

The only issue these mills have IMHO is the loss of "register" when you alter the height of the machines head. (it turns on the round column when you wind it up and down. Causing you to re-set the tools to the work).

Hope all that rambling is of some help?? It's late here in North Wales and I can sometimes go on a bit!!

Ralph.