Well, finished up various tooling side-tracks, and got back to the main event.

Spent a bit of time to make up a boring bar to line-bore the cylinders:

and a driving dog

and damned near ruined a cylinder assembly as the part shifted during boring... came out with a bore slanting off to the side...I'd bolted a bit of angle to the cross slide, and bolted the cylinder to that, and it was not up to the job.

soooooo after a longish pause for recriminations and practising bad words, went back to the 4 jaw, indicated the thing to pretty much zero runout and finished the job that way. Fixing the boo-boo has left me with a bore that is .0025 bigger than the plans call out, I'll adjust the piston size to fit.

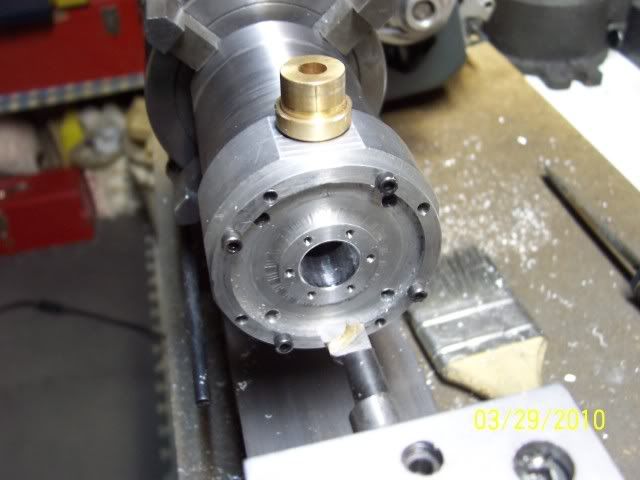

Once the bore was done, bolted on the head without moving the cylinder and bored the head for the piston rod bushing

Installed the bushing, and the head cover and reamed them to final dimension

Then turned it around in the chuck, re-indicated as close to dead nuts as I could, and did the 2nd head the same way,

and then all over again for the second cylinder assembly

And here's the stack-up:

This one got me worried for a little while!

Cheers, Joe