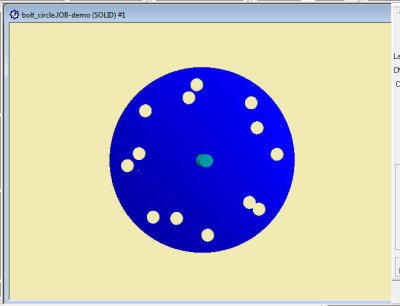

I acquired a wheel for mounting my spare tire for the Jeep, but it has a 5x5.5" bolt circle whereas the axles are 8x6.5". So I wanted to drill a new bolt circle. The first step was to determine how much the new holes would interefere with the old. I used a machining emulation PC program:

As can be seen, one hole touches and another is very close. I was able to vary the relative start angles, but regardless I would get nothing better.

The holes for 8-lug wheel studs are nominally 9/16", but unless they are perfectly straight the fit will be toom tight. Drilling 5/8" holes was needed.

Once the holes are drilled, it may also be necessary to bore out the center hole to fit the hub. I needed to increase the center diameter from 5-1/8" to 5-1/2". There was just enough room to do so. Having a hub nearby to test the fit is a plus (or else use the actual axle, which is less convenient).

Because the original holes in the well-used wheel were wallowed out, two of the new holes intersected with old ones. This isn't something I would recommend for normal use, but for a spare wheel it will work fine.