I stripped my Chester branded 7x minilathe down, intending to do some work on the bed and make a start on adding some proper gibs to the carriage. I also wanted to have a look at lubrication inside the headstock. I had squirted some white lithium grease in there (through the screw holes) when I got the lathe, but it has always felt a bit rough when swapping from high to low, and when turning the chuck by hand.

Here’s my ‘pride and joy’ at the moment –

The bed isn’t that curved – it is the wide angle lens doing that. The only sort of lens to use in the 6 foot x 6 foot ex-coal cellar that I call my workshop.

Anyway, this has now turned into a bigger job because I discovered a problem with the countershaft bearings that must have been there since the lathe was manufactured (if that is the right word).

Turning the shaft by hand (with the gears in the central neutral position) was very difficult and rough feeling. Bear in mind that this was without the motor connected, just the shaft itself turning.

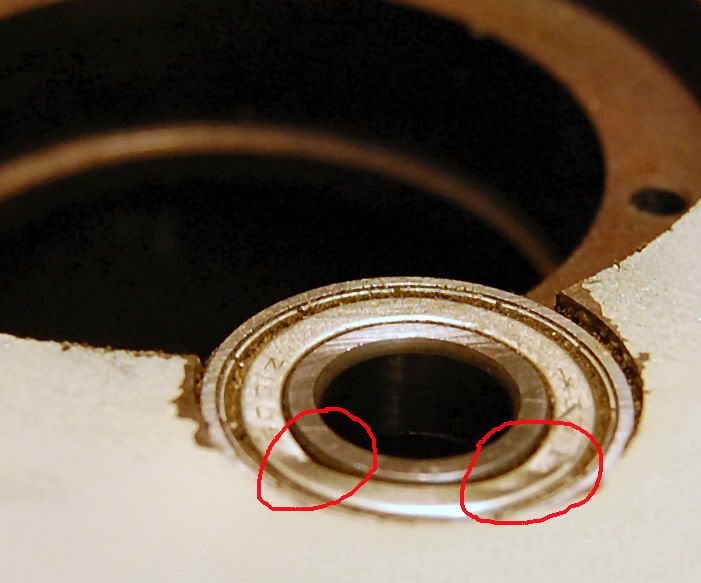

I hadn’t planned to strip the headstock but ended up doing so to find out what was going on. I got the countershaft out. One bearing came with it, the other stayed put. Both bearings felt as rough as a badger’s bum. Both were the same size, but with different types of shielding. The one still in the casting had two dents in the metal shielding (highlighted) –

It looks like the ‘fitter’ was having a bad day when he knocked this one in, or maybe it was already damaged before he picked it up. The other bearing has plastic shielding and shows no outward signs of damage. I think it is just a cr*p bearing.

So I’ve ordered some new bearings from Arc Euro. I had to strip the whole head down to do this job properly, so all will get a good coat of looking at and a generous application of the appropriate grease before it goes back together. If I can get hold of some metal gears in the very near future I’ll put them in – it would seem sensible while it is stripped. Trouble is, ARC are out of stock until early next year and I don’t want to order from USA just now.