You squeezed that in

Not squeezed in!, more built around!

I removed the end wall, and wheeled it into place while it was almost empty!...

...then the cupboards, lathe, and pillar drill etc all went in after...

Can I ask how is your feed powered/switched, mine runs whenever the mill has power and I'm not sure if it should?

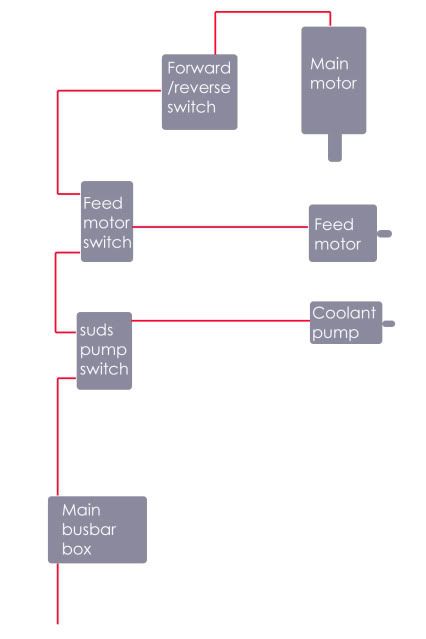

Here's a rough idea pic...

The wiring is via the standard Beaver switches:

1: In through the bottom busbar box

2: Up to the 1st switch - power to coolant pump

3: Pump switches input wires are piggy backed upto the 2nd switch - feed switch

4: Feed motor input switch wires piggy backed upto main motor forward/reverse switch

5: Forward / reverse switch wires out to main motor