I spent the last weeks (well, the week end only) to install Digital ReadOut system on my mill and lathe. 5 pieces, 3 for mill and 2 for lathe.

the work wasn't too difficult, apart for the Z axis of the mill and the X axis of the lathe (I suppose it's the X axis, anyway it's the cross slide)

I didn't take pics of the work, because it was a matter of simple drilling and milling job, but today, after having completed the task, I took pics of everything

mill Z axis

mill X axis

mill Y axis

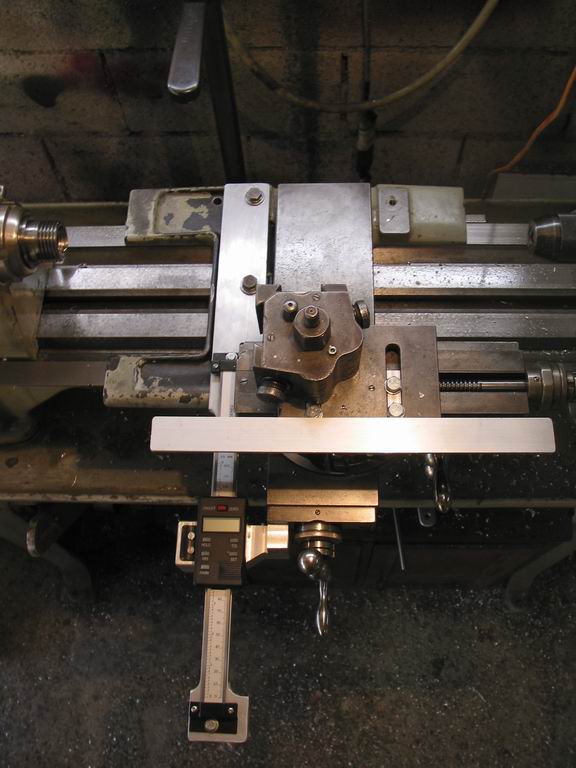

lathe, pics all together

in a first time I made this support for the cross slide DRO, to protect it (I wanted to partially cover it with a transparent piece of plexyglass)

but it was too flexible (the L shaped aluminium bracket is 3 mm in width) because it is fixed only at the centre of the cross slide and the DRO protrudes outside for the whole lenght. I wasn't satisfied and so I changed the project, I hope that the DRO, being away from the chuck, doesn't catch too many dirt.

I know that the position of this DRO isn't many comfortable, it would be better on the opposite side of the lathe, as people generally install it

but the Boley lathe has a vertical rod in the middle of the other side, that supports the lever to start and stop the motor, so this solution was impracticable.

the first tests that I have made today aren't so bad, it seems that I could drive the lathe as easy as before

all DROs but the Z axis of the mill are OK, and readings are the same as the collars suggest.

on the Z axis of the mill instead I have a little difference, must investigate on this (I was so proud just of that DRO, it was installed in a perfect manner that everything was invisible, but obviously it is the only one that has problems

)