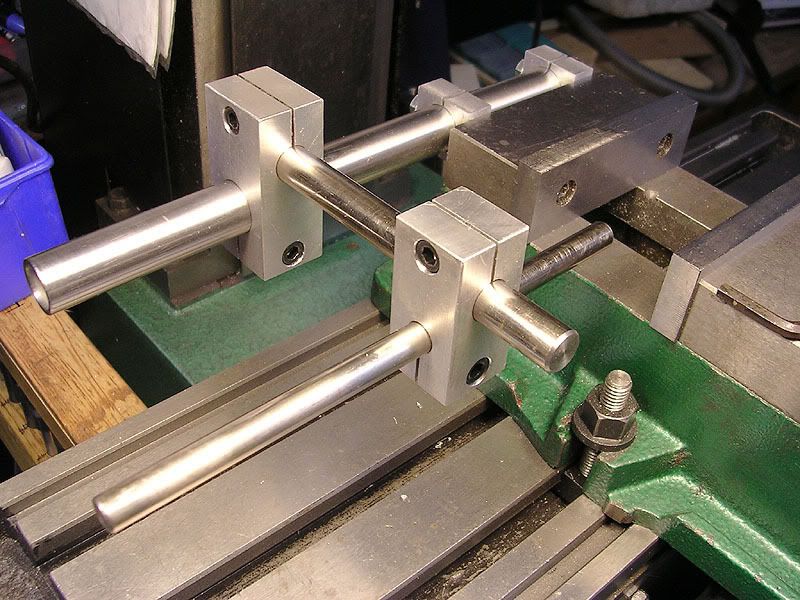

I made a stop for the vise on my X3 mill a while back but haven't used it much. It's made from aluminum blocks and some 1/2" and 3/8" rods I pinched from old inkjet printers I picked up here & there.

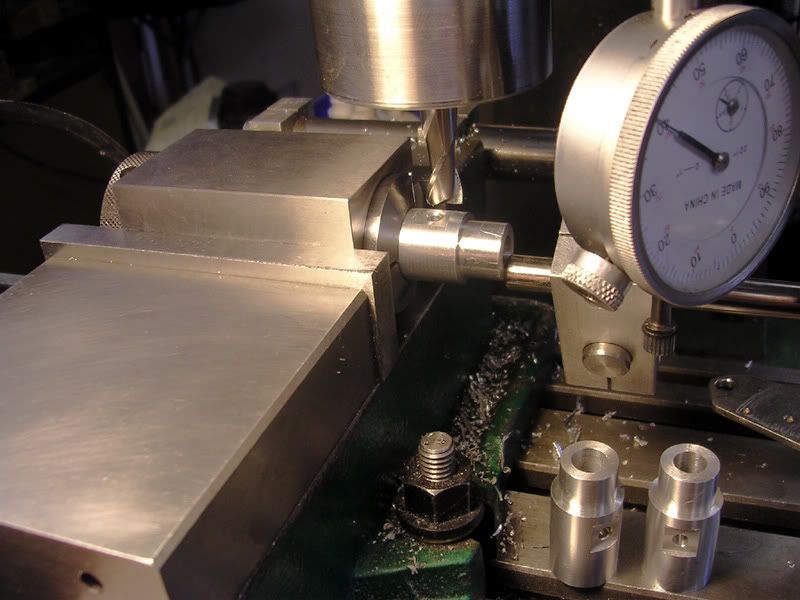

A paying job came along last week that it came in handy on. The job is making a few prototype venturis for a friend for a model airplane engine. I needed a way to positively locate the part to accurately drill the hole for the spraybar, mill a flat on one side, then rotate the 5C square collet block to mill a flat on the opposite side. The stop worked great and allowed the block to be remove & replaced as many times as necessary with proper alignment assured.

A side benefit was mounting a D.I. on one of the rods to accurately measure Z axis depth. I don't have a DRO. The clamps are made from 1/2" square CR steel cut-offs, some more printer rod and a few bolts & wingnuts I had lying around.

Not much MadModding going on this weekend but thought I'd share this little project anyway.