This is going slowly! I need

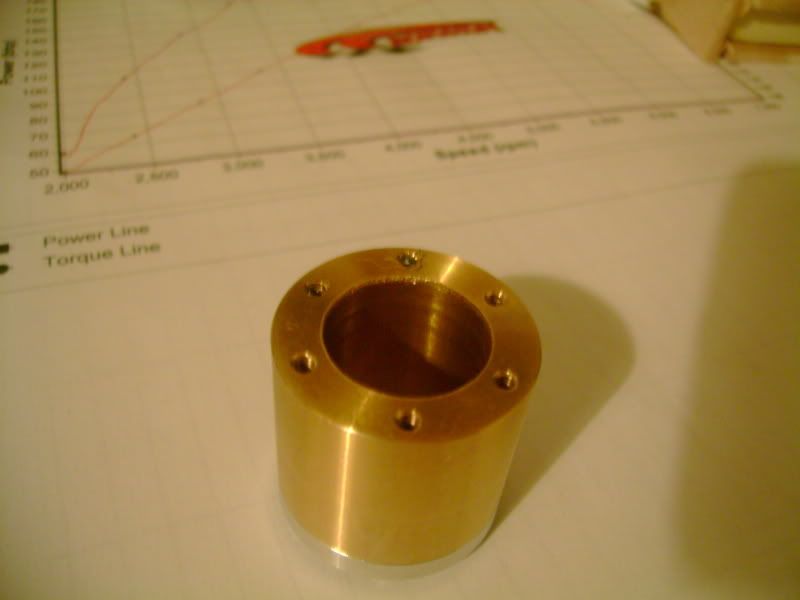

All I got done today was finish the cylinder and cover.

I put the cover in the lathe and made it run true the same way as I did before, brought the tailstock up to it whilst nipped in chuck and running slowly.

I marked the positions of the 6 holes by lightly scoring a circle of the right dia. with the cutting tool on the inside face, then indexed using the 3 jaws of the chuck and a small spirit level on each jaw getting them as near as I could to horizontal each time and scoring across the circle with the cutting tool.

Centre drilled and drilled through, it's tough stuff this aluminium though, made me realise both my no 50 drills were blunt so had to go through with 52 first.

I then put the cover on the cylinder and spotted through the holes on both ends. The 6 divisions are good enough not to be able to notice by eye but they won't line up in any position, only 1! I need a rotary table with compatibility to lathe chuck but this will do the job, so long as I spot the frame holes with the cover too.

I opened up the holes to 8 BA tapping size in the cylinder and started tapping the holes. Used a taper tap in the drilling machine to get them square then thought i'd just do it by hand with the plug tap so I could get more feel.

All was going well and I was just thinking to myself, I used to break taps like this .. I was so careless back in those days, am much better now. 10 mins later this thought came back and bit me in the @rse and the tap snapped!

Think my taps were pretty blunt. Without thinking I tried to get it out using a centre punch, which didn't work, just made a few scratches on the end face of the cylinder and a bit that pinged off hit me in the cheek. Could have been nasty if it were a bit higher, I wouldn't care, I'd had my glasses on 90% of the time too. Always wear safety glasses.

After conceeding I wouldn't get it out I thought well, I don't really need to. Luckily it was in the end that bolts to the frame, so all I'll have to do is tap that hole in the frame and put a dummy bolt in instead of drilling clearance size. 5 bolts are more than enough to hold it.

Here are a couple of pics. First of the frame end with the broken tap.

No one will be able to tell once it's together. Hopefully no more mistkaes!

On another safety note, does anybody wear gloves whilst they're in the shop? I know there are other hazards associated with gloves and machinery but I'm for ever getting little shards of metal stuck in my hands which can be painful and difficult to get out. How do people avoid this ...guess never touching swarf with bare hands would be a good start but I can't seem to avoid it.

Nick