Based on many comments here and elsewhere, and seeing some others' stands, I decided I need one before tapping one more tiny hole. While I intend to build a "standalone" stand, today's effort gets me a good part of the way and yields a functional tool.

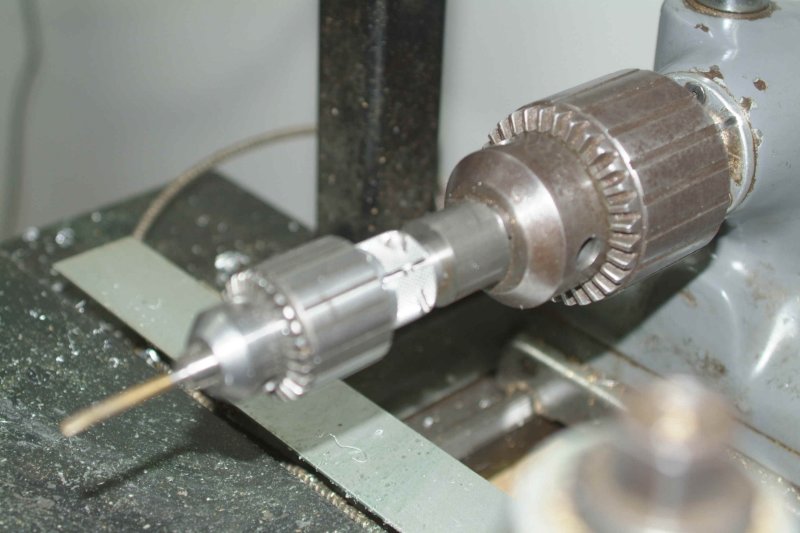

I recently purchased a 0-1/2" keyless chuck for the mill, so I had a spare 0-3/8" keyed chuck available. It has a straight 1/2" shank that I held in the mill wth a collet. The first job was to make a way to turn it with a tap chucked. This was made from 1" aluminum round, knurled and split, with a 6-32 locking screw. Then I took a 3" piece of 1" aluminum round bar, turned down one end to 3/4" to fit in a R8 collet, and drilled/reamed a 1/2" hole through. Here's the pieces:

With the round bar held in the mill spindle, I slide the chuck shank up into it and move the piece to be tapped underneath. Here I'm tapping the top of one of my new engine columns.

The chuck can also be used on the lathe, as the bushing I made for the diestock is also bored 1/2":

The next phase will be to make something similar to what Stew built, shown on another thread.

It might be a bit better if the knurled ring were a bit larger, but