Hi all,

Allready when i introduced myself,there were peeps anctious to see what i was gonne make first on the lathe...here it is;

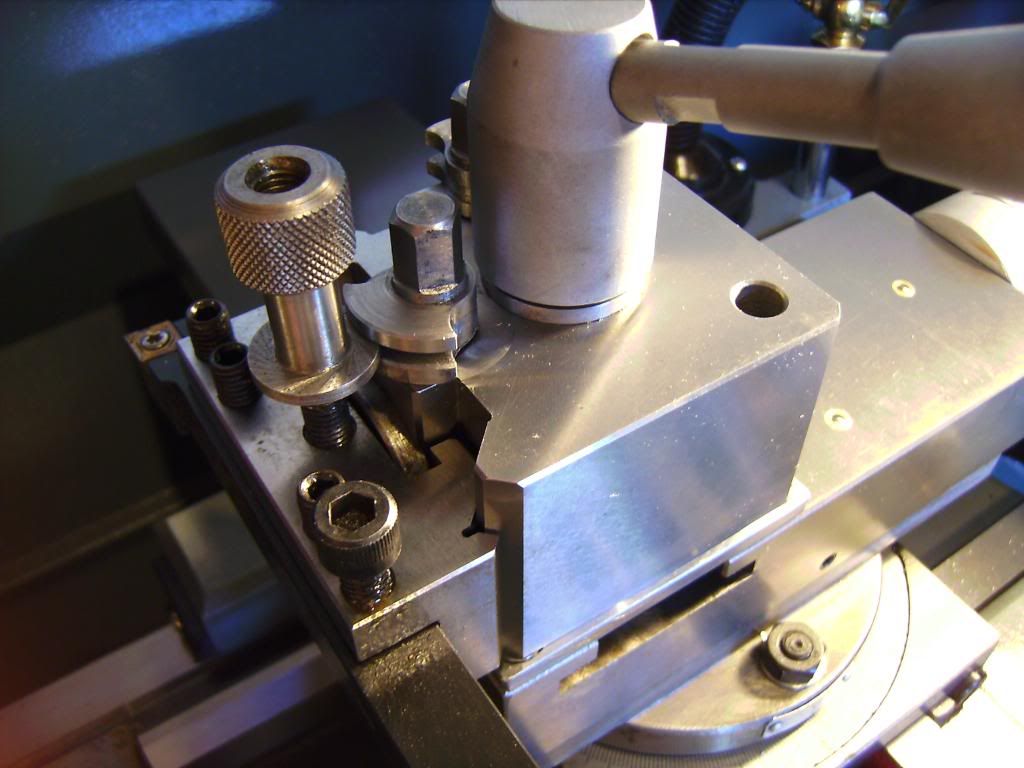

The toolpost that i bought sat only on a small diameter,not having enough support,it would make the cuttingbit wanting to slide under my piece when trying to part something

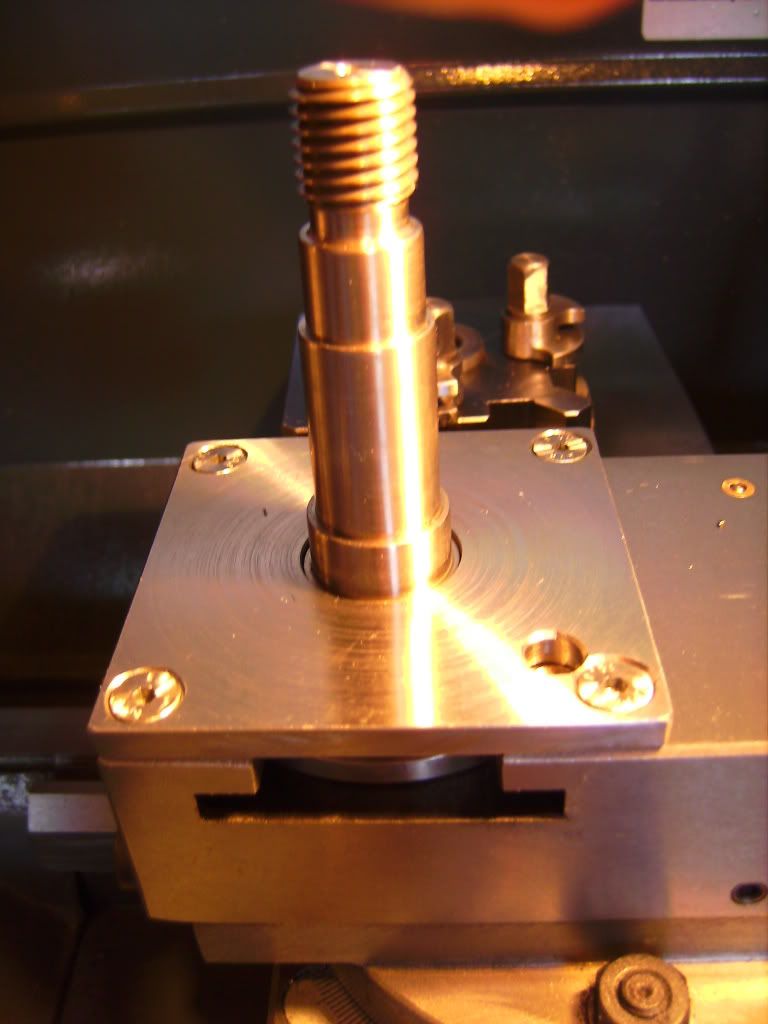

So i made a new rod with threads;

Connected it to the original nut and secured them with an internal hex bolt M5;

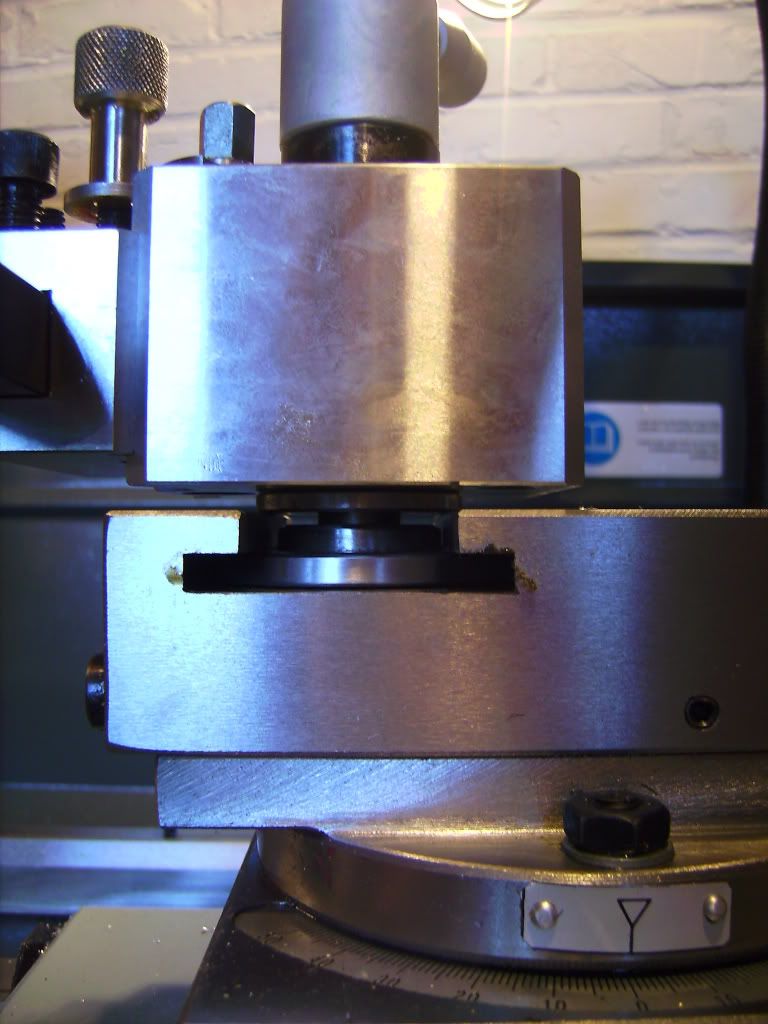

Drilled 4 holes in the sled and spacer which i needed to make the toolpost stand high enough to be able to reach center with all possible tools,slipt the spacer over the new rod and secured it with 4 bolts M5(I made absolutely sure i wouldnt drill anywhere in the guides of the sled first);

Made a spacer so the handle to fasten the motherblock would face the right direction when tight;

Assembled everything and there!! a nice tight sitting toolpost;

Hope to be a help for anyone else with this.

Danny