Also known as.... "Wondering why the drive belt fell off!!?"

I had a few hours to myself tonight, home early from work and no pool, snooker or cars to fix

So I thought I'd have a go at my finger engine designs..... Not if Murphy or Sod have anything to do with it!!!

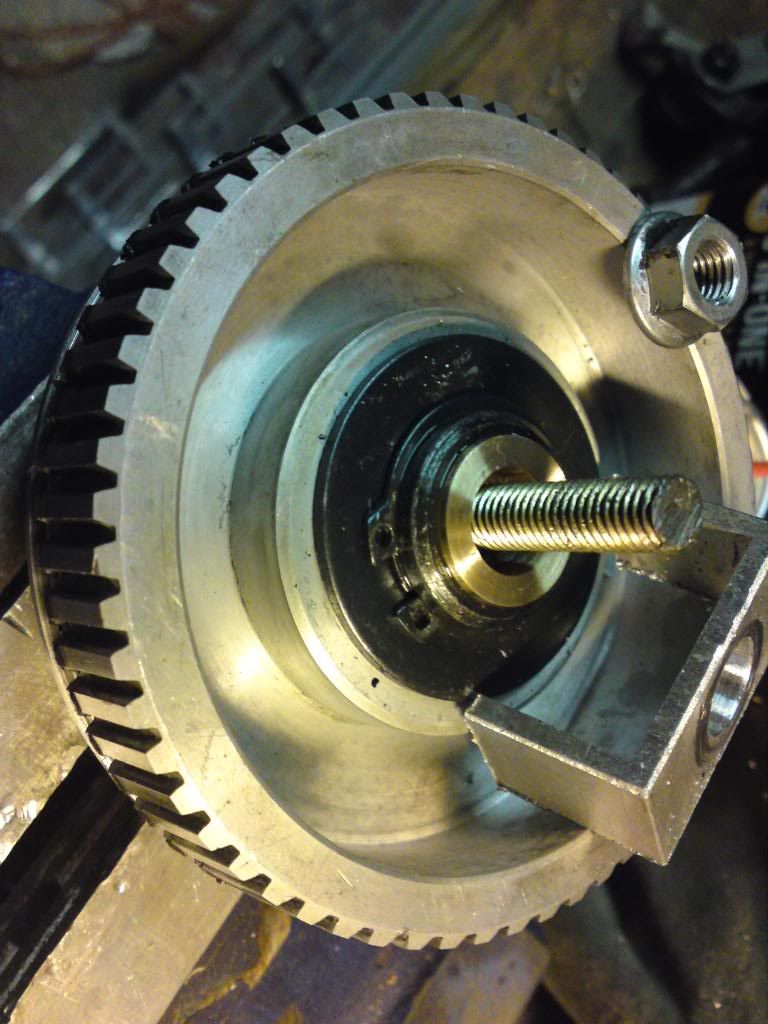

My main toothed drive belt fell of my lathe

After a minor investigation it was very obvious why..... My clutched main drive sprocket was wobbling like a jelly

After a quick strip down it was clear why,

The spring loaded oil way (little brass bit next to the circlips and the washer) had a big lump of @%$! in it and had not allowed the oil to pass through to the rear of the assembly.... Can we all say "dry bearings are bad"?

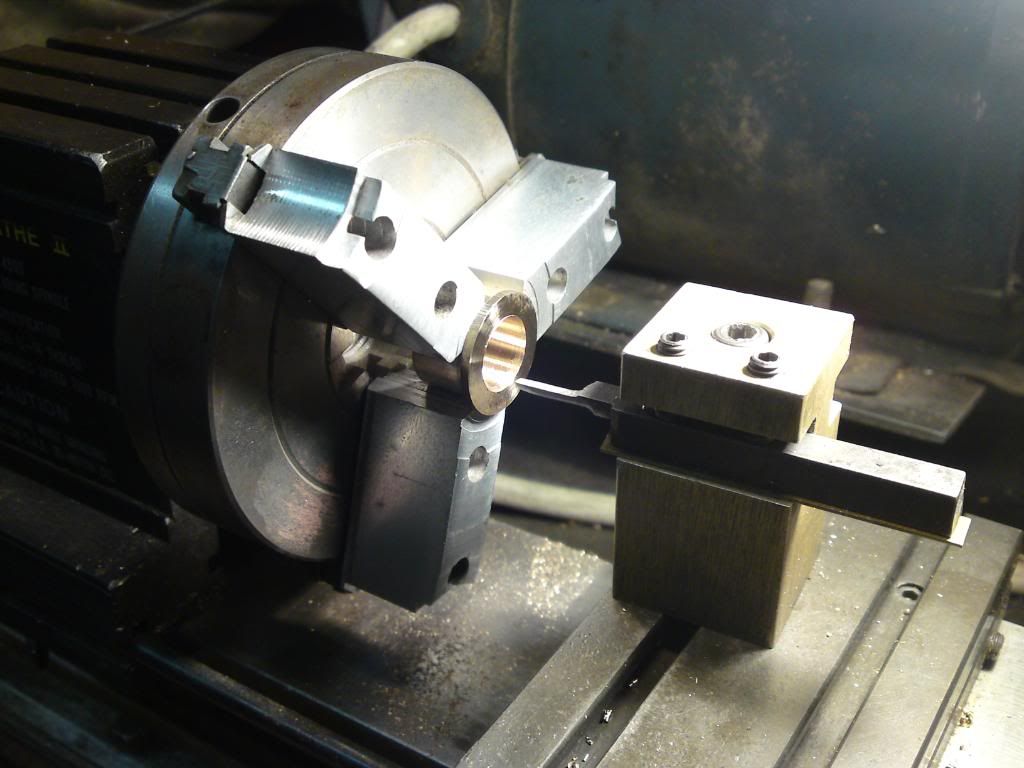

A 14mm ID bush..... For the 11.95mm shaft!

I removed the bush with a few small taps using a drift through from the other side.

Then thought to myself "how the hell am I gonna make a new one?!"

I thought about the mill and then was struck by a bolt of obviousness.... Use the lathe!

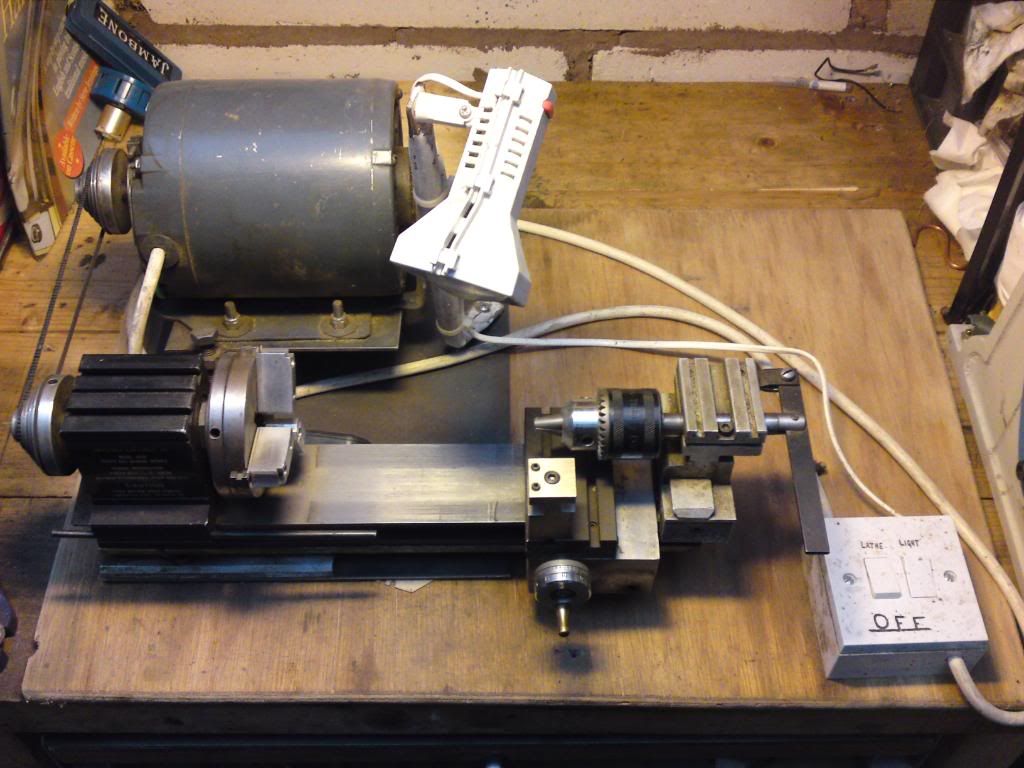

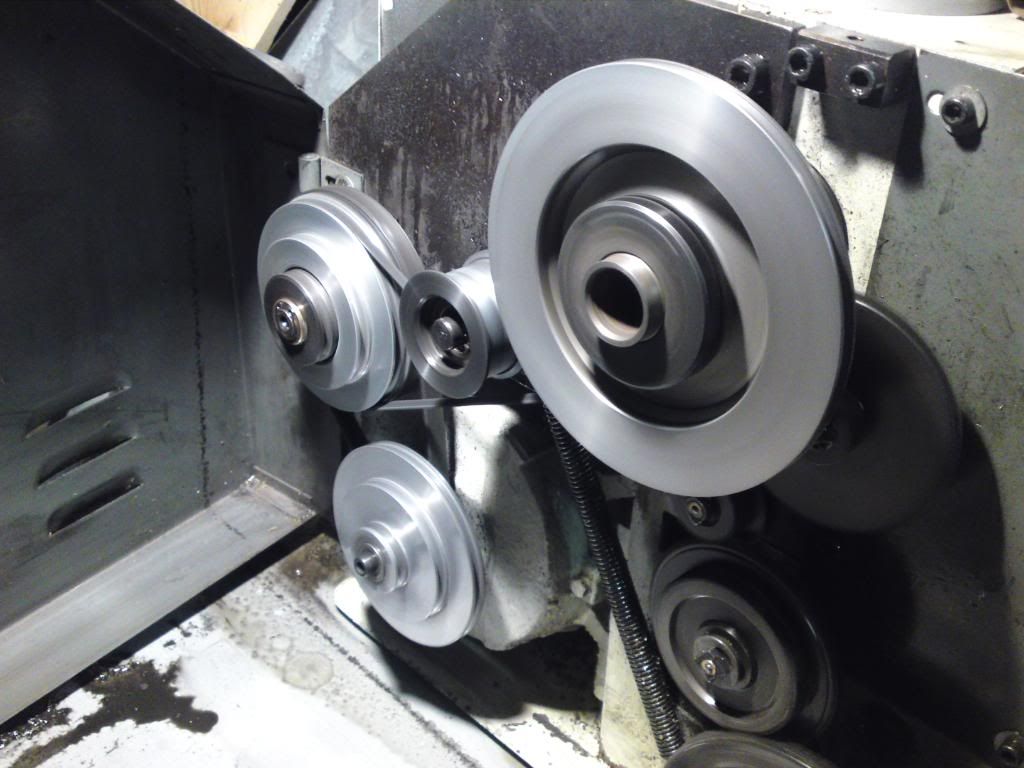

Not the 9x20.... This one

(peatol/taig lathe)

My first personal lathe, he's been in storage for nearly 2 years..... Still purrs like a kitten

So a bronze bush was made..... These little lathes are fun and super accurate I just had to remember how to work it!!

The difference between the two....

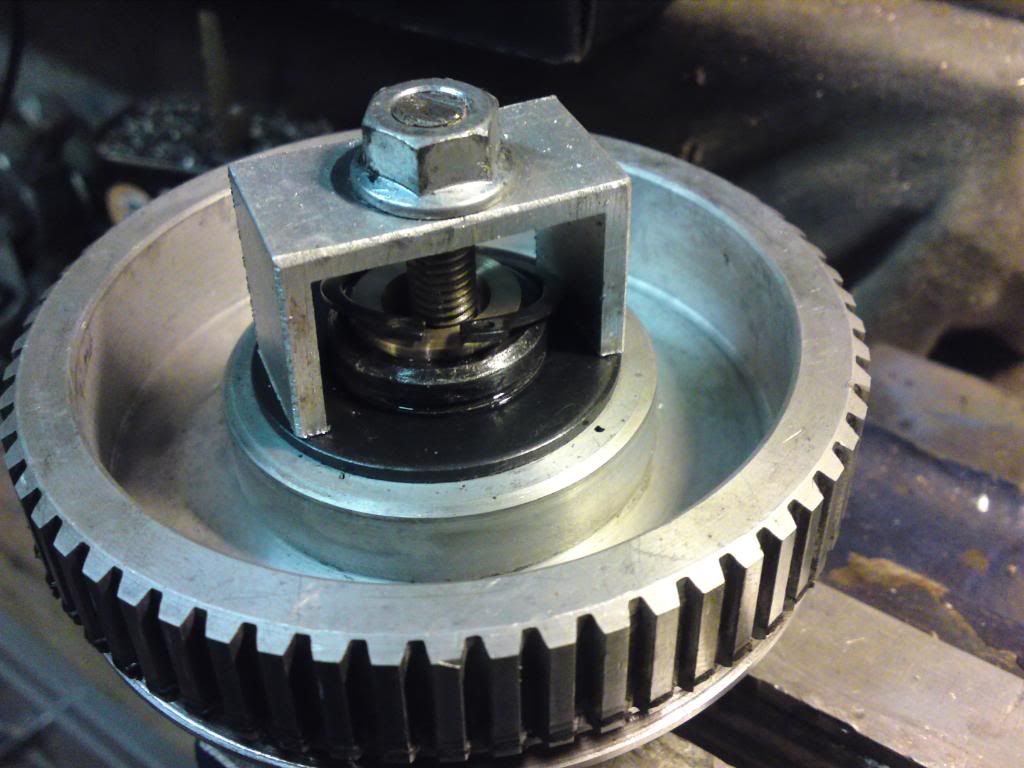

One final issue, getting the clutch mechanism back together.... compressing 5 springs and fitting a circlip.....

Well, a little thought and 5 min's later I had it sussed, a mini spring compressor. Hacked out of a piece of ali box section, it worked a treat

All back together so that I can use it when next I get a few hour to myself....Not for the rest of this week, Pool trophy night, a landrover Diff' to replace, a gearbox out and in on a Vectra and a second hand door to fit for a foreigner on sunday!!

I think I'll be lucky enough to get some rest let alone some "me time"

Let this be a lesson, when you hear a squeek..... Investigate, don't leave it for a few months!!!!

Ralph.