Ok...

Parts came. Went together easily... Then it sat. I kept seeing things to improve. My time was short so I never got to implement them. I decided to rebuild it before I even used it. I ordered the parts to convert it into a different CNC Router. This one was also on OpenBuilds.

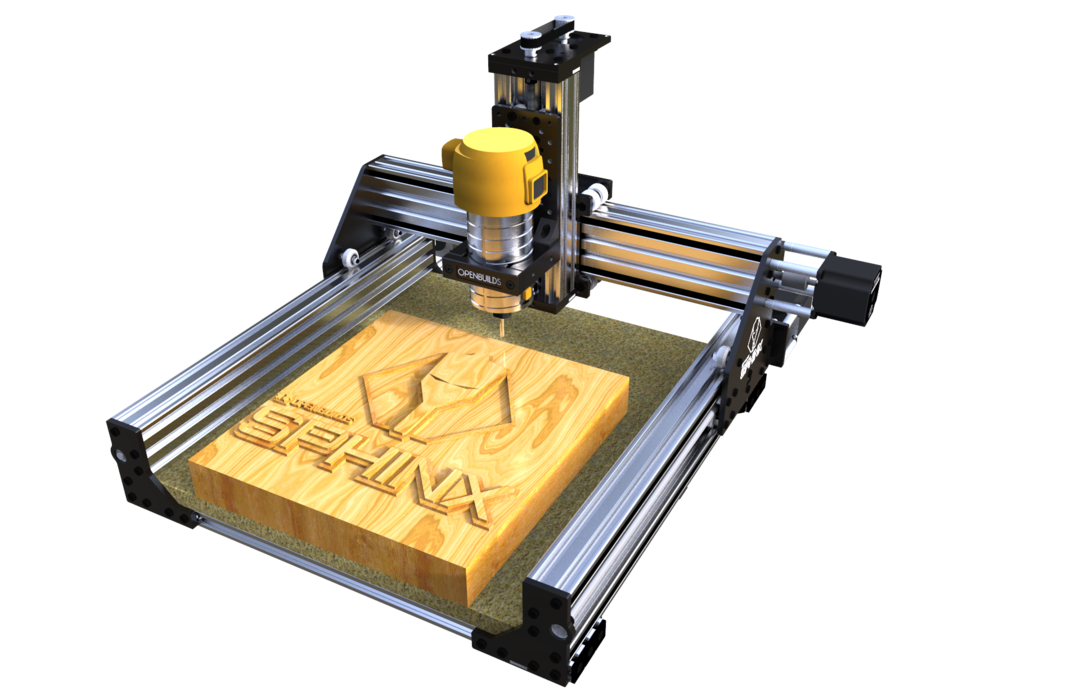

The Sphinx55

I ended up getting it converted and was able to cut some stuff. Did very well with wood. I was able to get some 3D Carved signs made for presents.

It could cut aluminum... but the cuts had to be light and speeds/feeds almost dead on. I traced a lot of the quality issues I was having to some play in the Z axis. I knew this wouldn't be the stiffest things in the world, but I thought it would be better than what it was.

I started researching ways to help stiffen things up. I then found

THIS:

Oooh. I like that. But, I didn't like the 12mm linear rails. I have those on my Ender 3. They are fine for a printer. And I am quite sure, about a million times stiffer than the stock wheels. I just didn't want the 12mm.

I email the guy selling the plates and ask him about a set of plates for the 15mm rails instead. He tells me that he designed a kit for the 15mm rails but has not yet machined a set yet.

Sign me up!

I think to myself... While I am at it. Why not increase the footprint. Right now it is at 500mm by 500mm. Let's make it 1000mm by 500mm.

Ordered a flurry of parts

Aluminum extrusions for the base

1000mm C Beam and Acme Screw for the X axis

Plate kit from Blue Ox Solutions

15mm Linear rails and bearing blocks (1000mm and 500mm(2))

A new Z axis actuator from CNC4Newbie

A bunch more bolts/nuts etc...

As soon as everything gets here, I will start tearing down and rebuilding.

[TL/DR] I am on the 3 rebuild of a CNC router to add 15mm rails to it.