Hi

Chester Comet lathe.

The numbers on my angle graduation strip wore away years ago and setting angles has been a pain.

I just started making some pullys to convert my minimill to belt drive ( dont ask

.

I came up with this quick way of doing it.

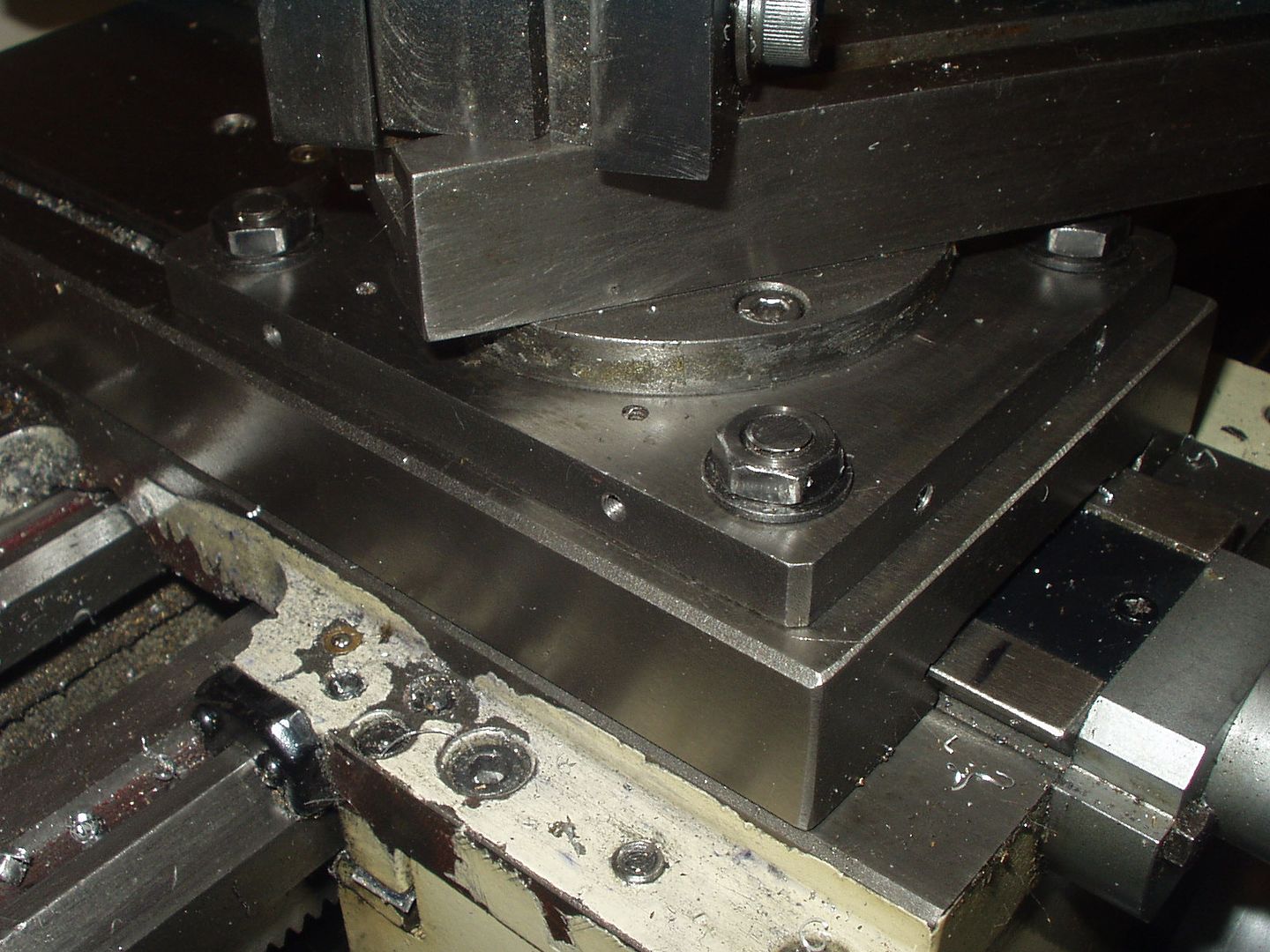

this is the plate the topslide mounts on to,

I drilled two m4 holes on each side and at the front.

now I can quickly fix a steel strip on the side and use a perspex gauge to set the angle.

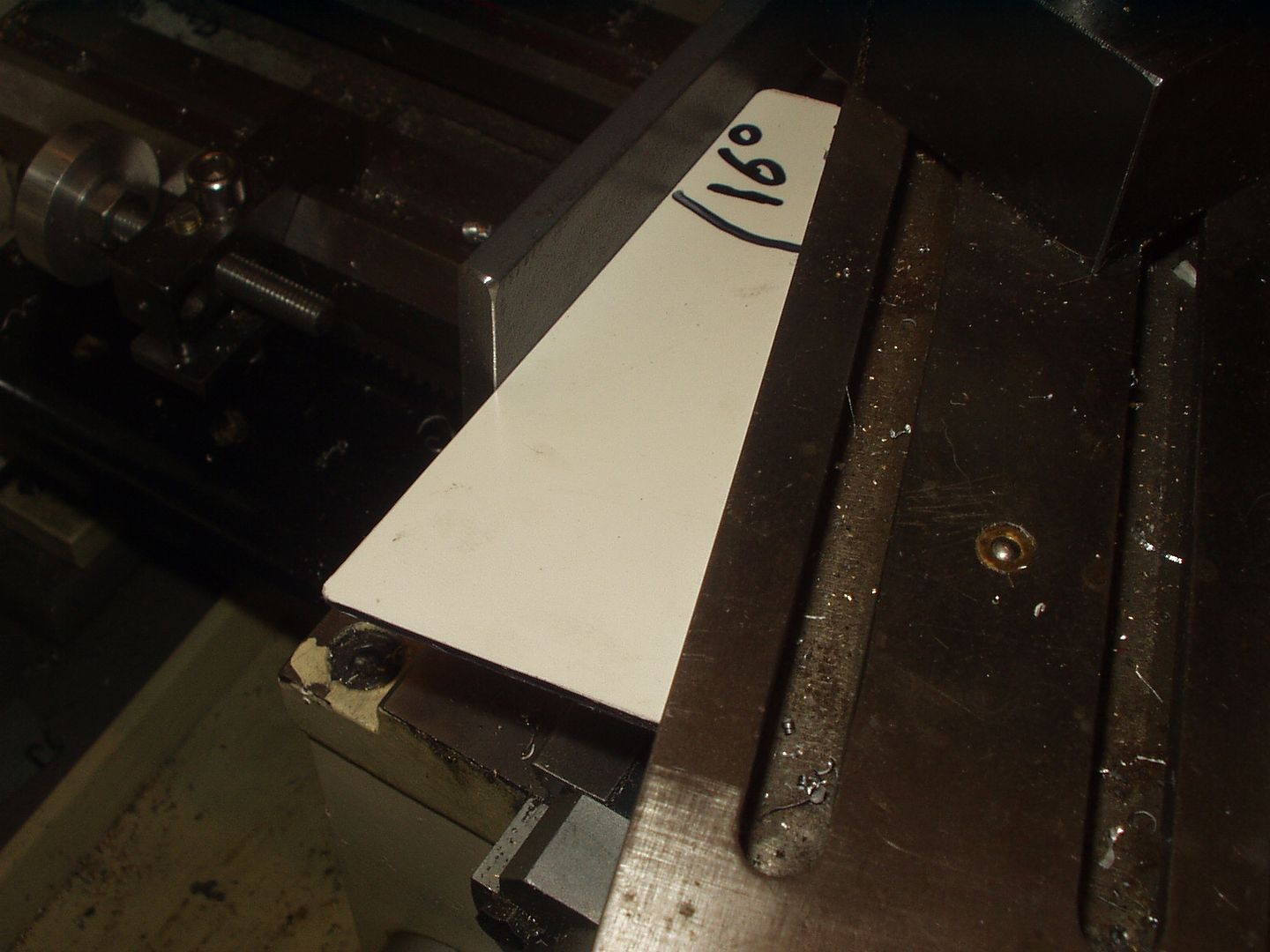

here's one for the pulley,

and one on the front for screwcutting.

I works a treat and it's quick.

the angles might not be accurate to 30 seconds but they are consistent.

hope this is of interest to someone.

Oh, in case you did ask, I trashed the low speed gear in the housing.

cheers Roy.