I have had a dial gauge on my Taig mill for years, and always had the intention of machining a block to take a rod that can be used to set the dial gauge mounted at the top of the Z. Well, I kind of got round to it. Whilst doing other work I designed what I needed for 3D printing.

The first part printed was the body to hold the rod and take a small alloy draw bar for locking the rod in position.

This took about an hour to print, as it was printed at 0.1mm layers. Once the print was done it needed a little cleaning up and the bores reamed to size, for that reason it has the print software set to 3 side walls and 4 solid layer top and bottom. Next job was making the little ball handle, this is also a practice run for the printed Quorn handles in the future.

I'm using the splined perspex inserts, as they work so well for this kind of stuff and they are easy to make. In my case a tight press fit, but they could also be glued in if a little loose.

If my machining had been as good as the printing you wouldn't see any gaps round the splines. However, I set the indexer by eye and goofed the spline depth to machine in the perspex on the first two. Still, no one will see them, will they lads

Little bit of lathe work to make the drawbar, it hadn't been cross drilled at this stage, as rain was interfering with my 5 second commute from drawing office to workshop.

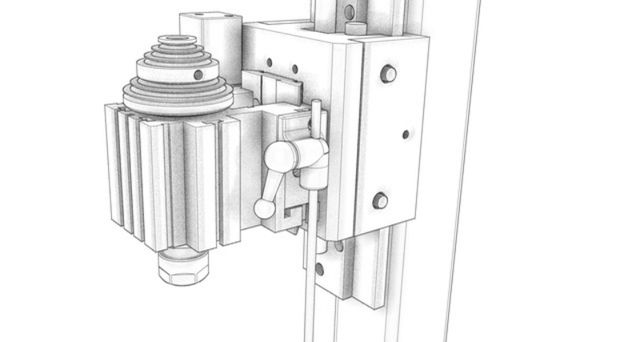

At last, final assembly and test. About 1/8th of a turn on the lever releases or locks the bar in place. I had hoped to make the tee nut for mounting but rain really has stopped play, it's bouncing down here, so calling it a night.