!!!UPDATE TIME!!!

Well I got my stuff from The Edge this week.

Im still waiting on all the parts from my waterjet guy, looks like it may

be a couple of weeks on that.

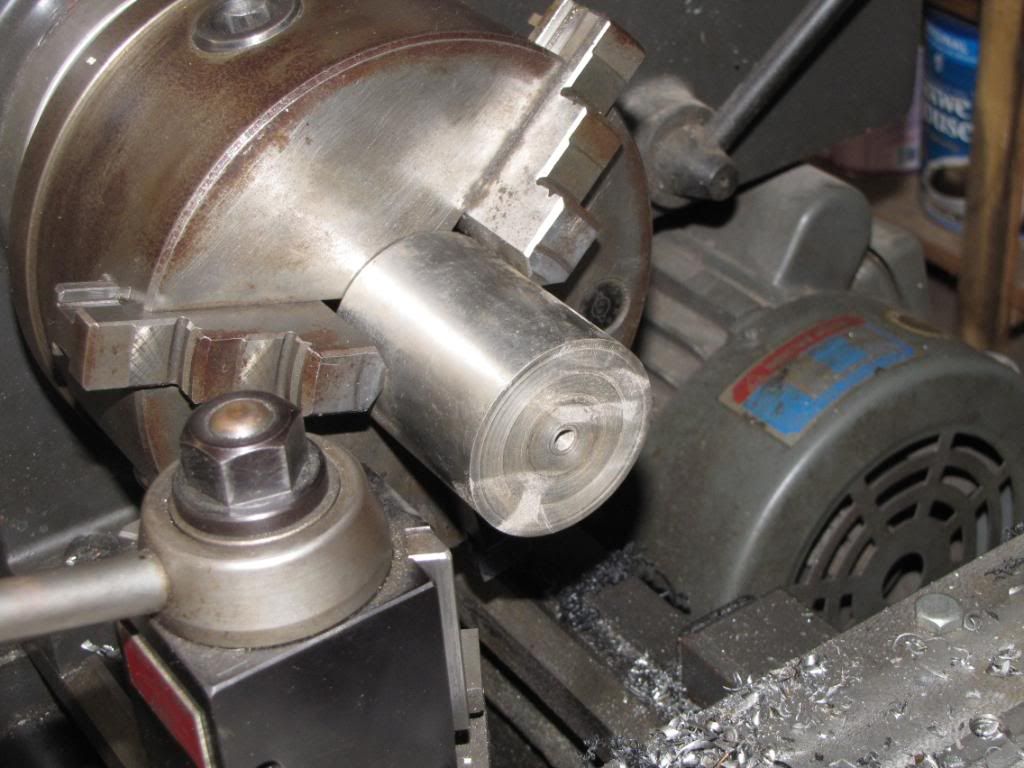

So I knocked out the front spindles. I used preheat treated 4140,

It comes in around 30 rockwell. It is not too hard but stiffened up a bit.

And machines very well, IMO better that annealed.

Here are some pics of the turning, I didnt take any pics of coping the end

to fit the spindle tube but it was straight foward. I just made a 5deg angled cut with an endmill.

Today I went and picked up some aluminum for the gas tank.

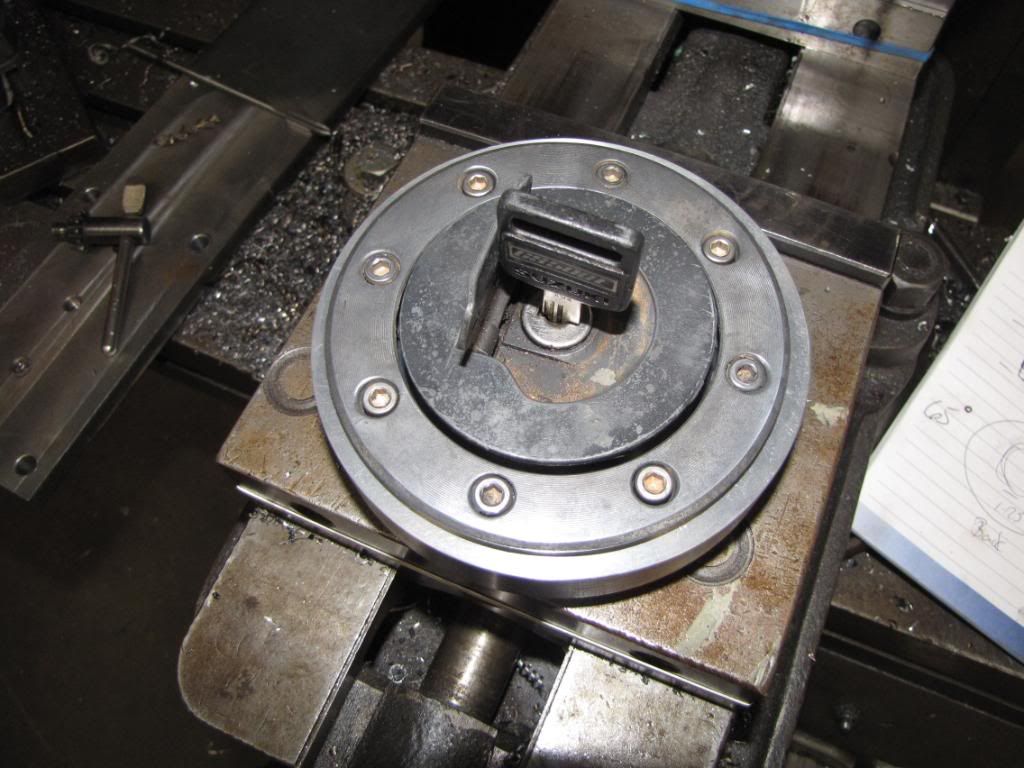

Then I decided to work on a tank lid. I really wanted to use the

cap off the GS500 tank. It is a cool flush mount cap.So I had to make a recessed

piece to weld to the tank top, so that I could use the flush mount cap.

Heres a pic of the tank. I had no intention of using it originally

so sitting out side it got mud and paint on it.

Under the cap.

First thing I did was make the center plug out of some stainless steel.

This is where the locking section goes.

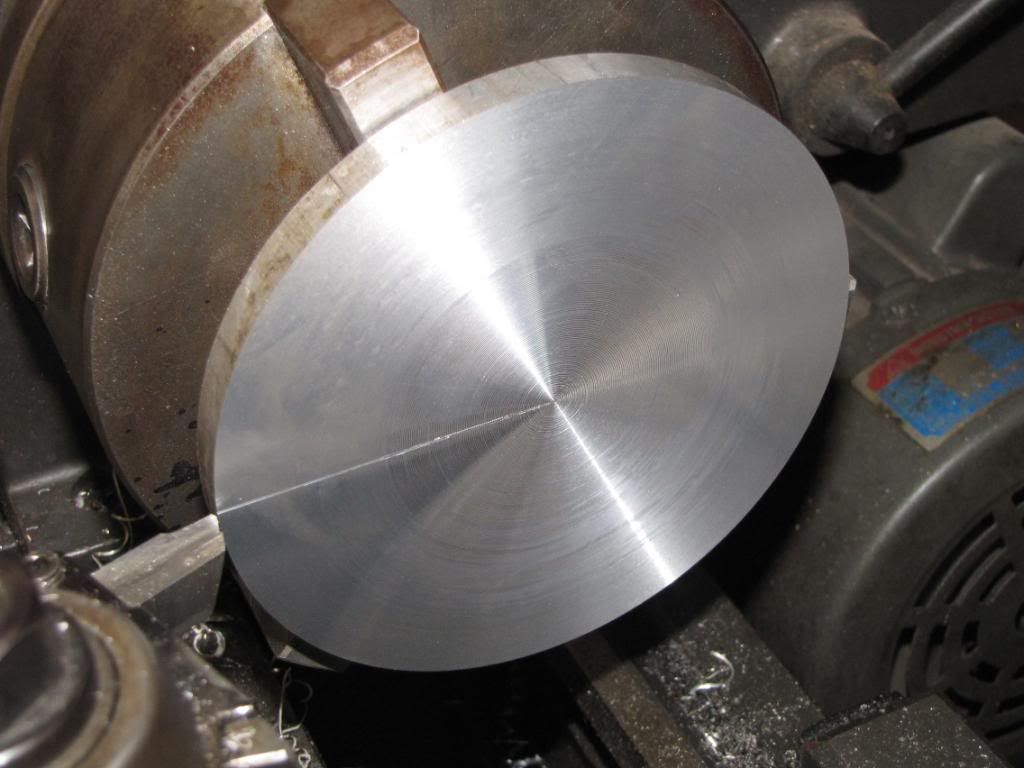

Next was making the recessed piece that would weld to the tank.

Sawing took almost 45min with my dull blade.

Chucked it up, faced and turned back as much as I could.

Then flipped it and faced to length and turned back the other half.

During the last facing operation I used the turning tool to scribe a center line for locating.

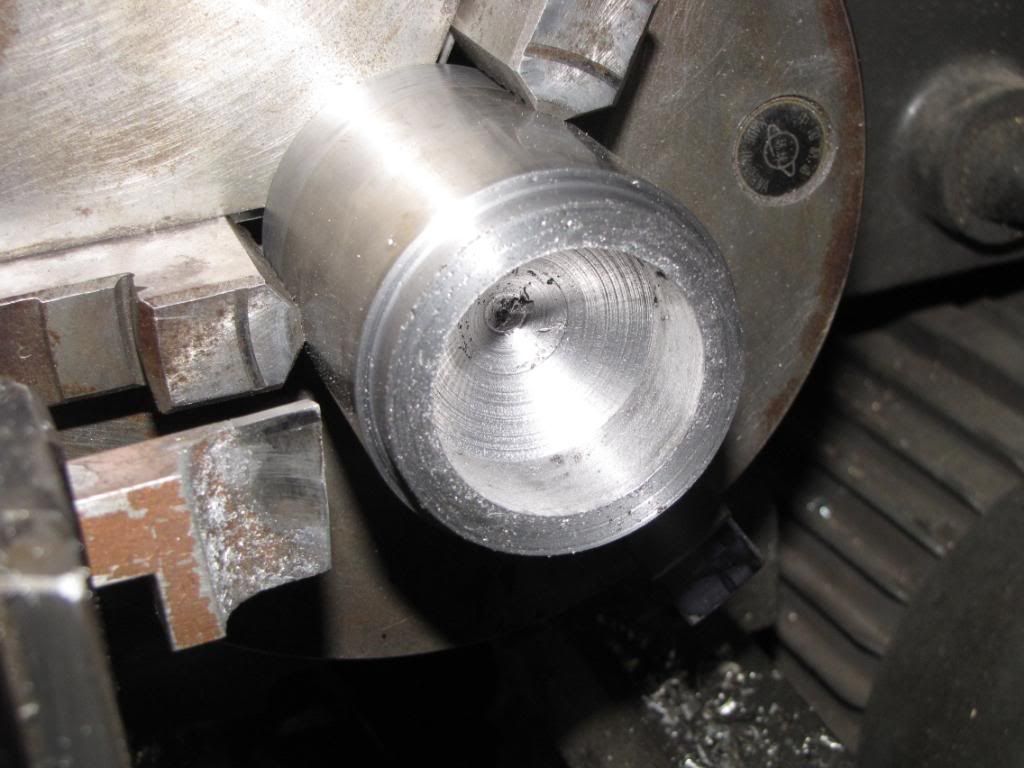

Then, I bored the center section, to the correct depth for the cap.

One thing I noticed , was that the center of the filler tube (SS piece)

Needed to be off center of the recess in the alum. On the GS tank I measued the offset at 3/16".

This has to do with the way the cap hinges and for the locking mechanisim to clear.

I mounted the 4 jaw chuck and got my part mounted so it was offcenter .188".

I then pressed my SS piece in, I wanted to keep my orientation in the 4 jaw chuck so I could bore the

SS piece so I used the tailstock as to help persuade the two to mate.

Well I just realized I didnt take a pic of the finished part. LOL

After that last pic I bored the SS to diameter, then put a 60degree taper like is on the

original. Then polished it us.

Here is a pic with the cap mounted.