A good 10hrs later, second part of the first casting done. Quick clean up, pulling off the support material and push them together for a trial fit.

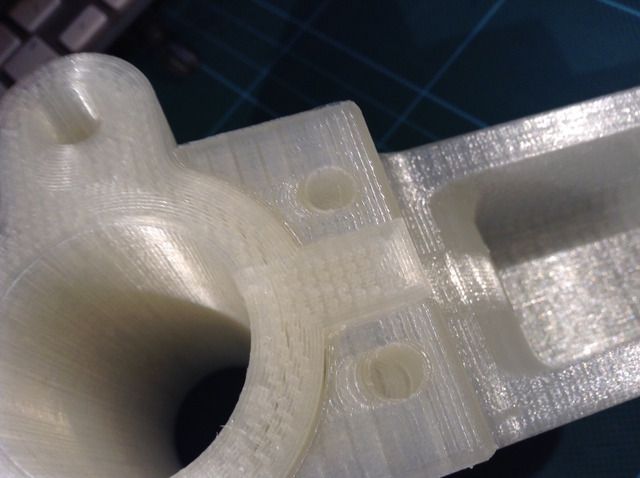

This is the fit with no clean up. Needle file will knock off some of the small blobs on the mating surfaces.

I won't know how accurate my centres are till I can put some bars in. Theory has it any error should be the same in the next part printed, so hope the centres are equal, next print will confirm that. I picked up my Perspex rod today and the 30mm is a very snug fit in the vertical column. I'm a gnats under on the 25mm, if the hole is elliptical, "Norman" it will get a skim if thats the case.

Last one for now showing the quality of fit and the holes for the dowel pins, they probably will be fitted with epoxy, but more to grout them in than glue. I'm a lot happier in the print quality on this second part. Once this section gets the bars in and welded, I can skim the underside to get them true.