Oh this has to class as a Mad Mod.... 14hr delay in hoovering the stairs !!!

My other half bought a new Dyson from Aldi, she loves her bargains. So muggins job was to hoover the stairs with new light weight model than the old upright. Break out the stair tool and join !!! NOT.

Thank You Mr Dyson for changing the fitting size. So

3D print time.

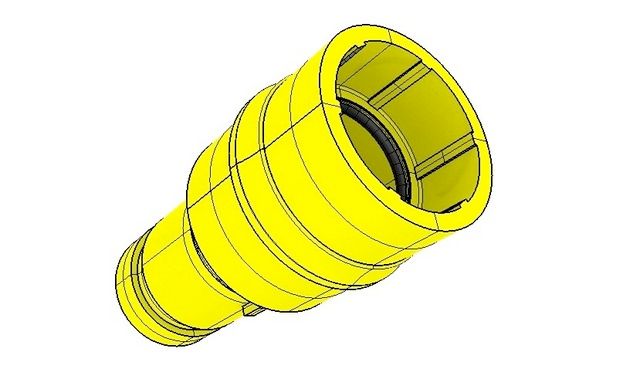

Couple of hours measuring parts resulted in above CAD model, including O ring... Oooh getting fancy now. 5hrs later I had a print.

This would be 1:30am I finished the print, and join..... NOT !!! WTF....

My measurement of the stair tool internal bore was wrong by 1mm. In all honestly it wasn't where I could reach with the calipers, thats my excuse. Out to the workshop and fire up the lathe for some very gentle boring to open out the larger end by 1mm. Bye bye to my O ring, so that was broken away to get at the bore. Slow machining cut and sealed the surface as I went, the end result was the bore to size and no ragged internal surface as the plastic rewelded into a thin skin, as seen below the step.

This time "click" it fits and the other end also fits a treat. I had spent some extra time reverse engineering Dysons locking lug, before realising I only needed the central part and not the rest, oh well I have the design for any other fitting I may design for this vac.

Just goes to show traditional machining still has a place. I modifed my 3D model to correct for the bore and take out the O ring. All finished by 3:00am, isn't insomnia great...

Stairs got done this morning, the look on my other half's face

Priceless.

To state the obvious I could have just used the upright vac

Wouldn't be a MadModder if I did that.