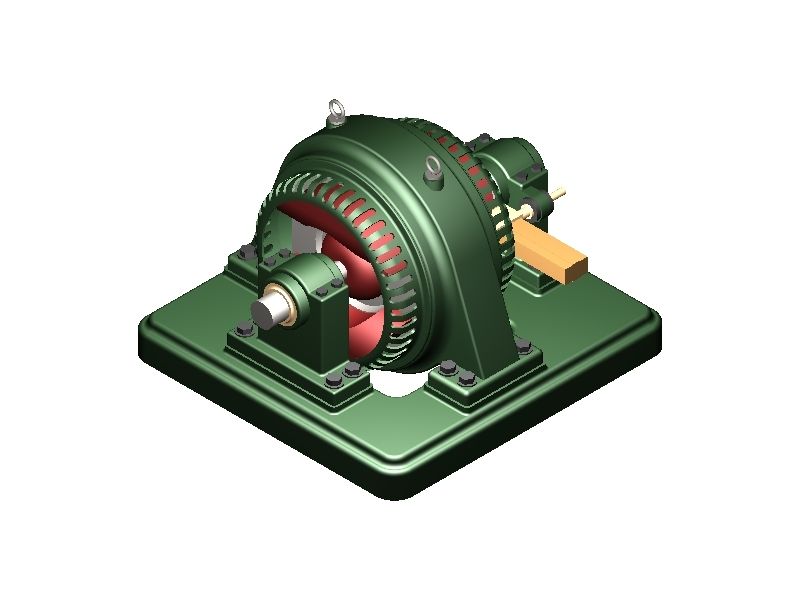

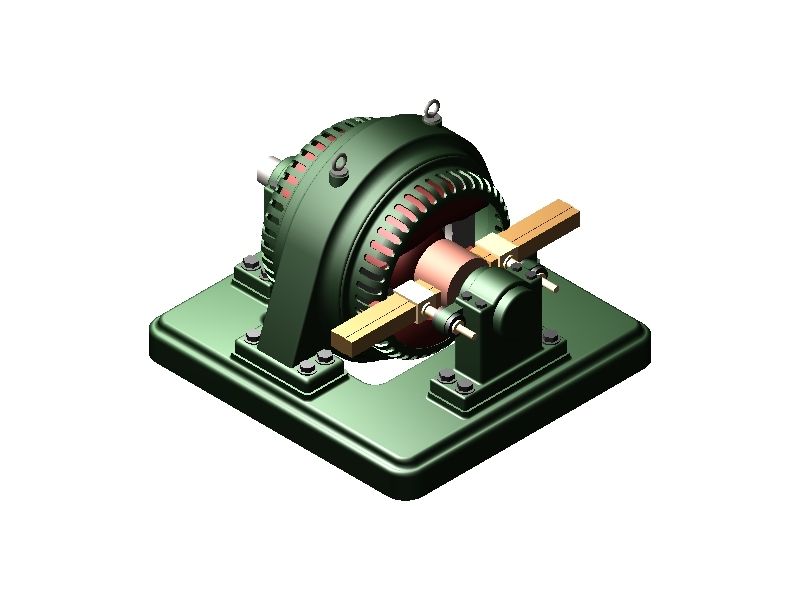

I wanted to model something to do for my Elmer mill engine so came up with this generator based on the fields and armature from a vacuum cleaner.

The various parts will be machined from solids.

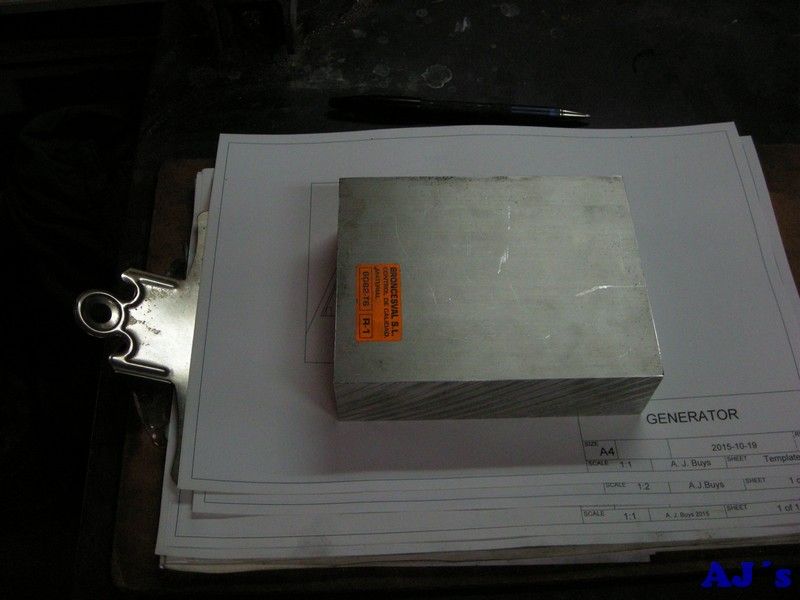

This piece will become the main housing.

A template was printed and glued to the piece. It was set up on the mill and cut with a slitting saw to mark where to cut off some of the excess.

The centre of the main bore was located and drilled 12mm for location on the rotary table.

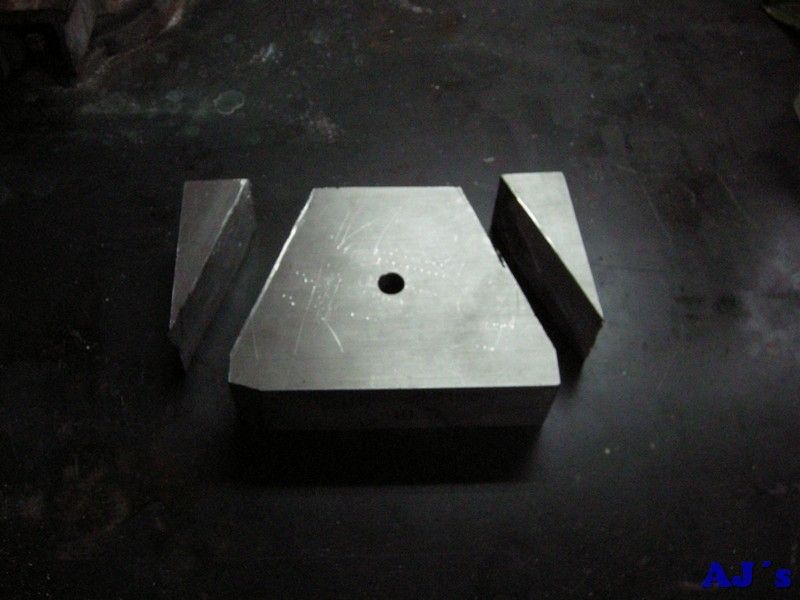

The excess was cut of with a hacksaw.

The First side was milled.

The centre was milled out halfway.

Then it was flipped over and relocated.

The second side was milled.

The centre was milled out.

The housing was set up directly on the mill table and the centre located.

It was bored to final dimension.

Then it was set up in the vice with the mounting surfaces level.

The surfaces were milled to dimension and holes drilled and tapped to mount the “feet”.

It was flipped and the holes for two eyebolts spot faced, drilled and taped.

All done and with the field fitted.

Cheers

Abraham